Multiple segment steam stripping method for catalyst

A technology of catalysts and ready-to-grow catalysts, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve complex process, difficult to realize and control cooling and heating methods, and small temperature range And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

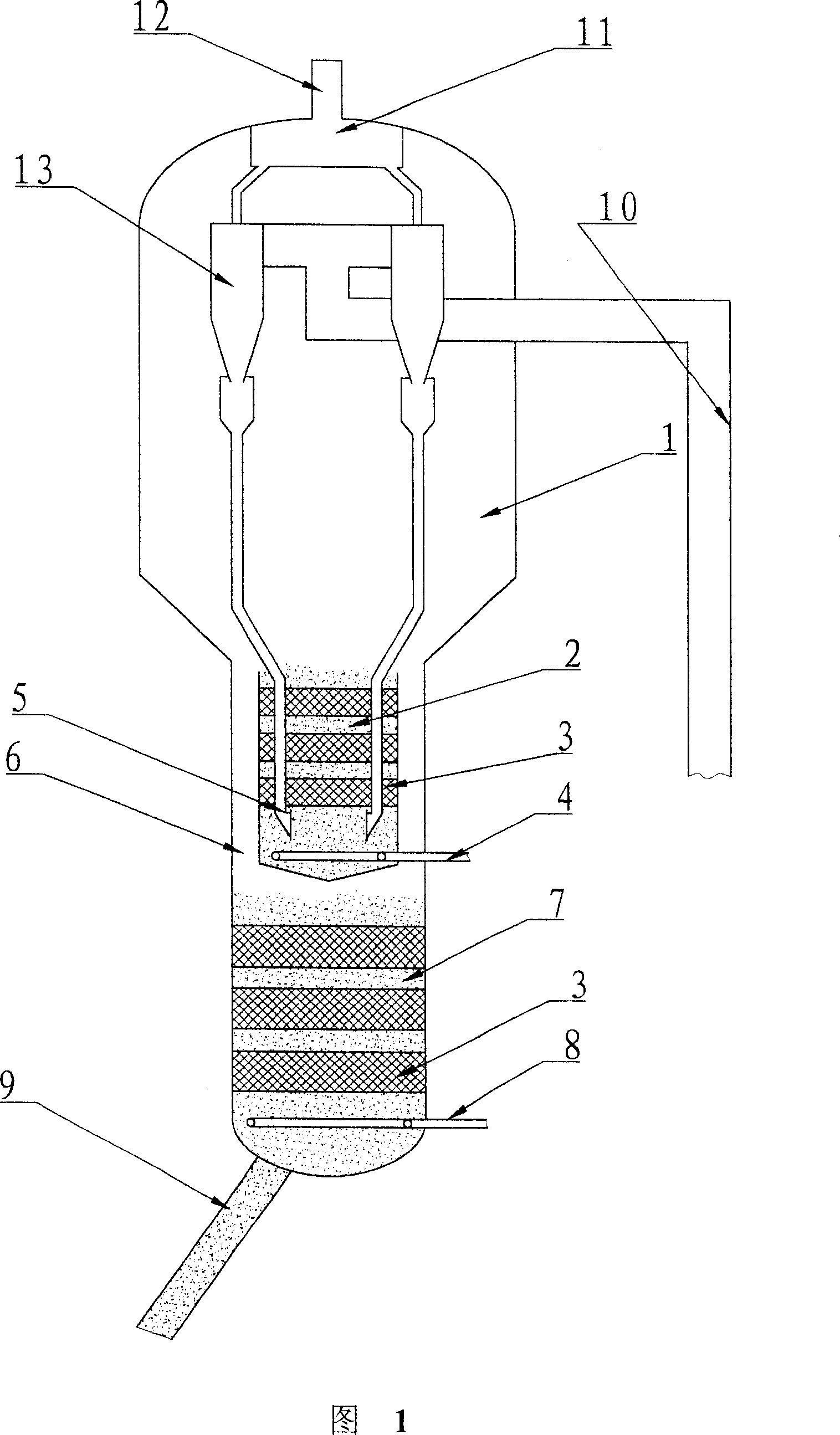

[0024] Embodiment 1: As shown in FIG. 1 , the oil gas and ungenerated catalyst after the reaction from the riser reactor 10 (part) enter into the cyclone separator 13 to preliminarily separate the oil gas and the ungenerated catalyst. After the oil and gas from different cyclone separators are collected into the gas collection chamber 11 of the settler, they enter the subsequent fractionation system through the pipeline 12 for subsequent separation of products. The spent catalyst separated by the cyclone separator 13 enters the bottom of the first stripping section 2 through the dipleg of the cyclone separator, and the stripping steam is distributed in the first stripping section 2 as uniformly as possible through the distributor 4 . Under the action of the stripping steam, the catalyst flows from the bottom of the first stripping section 2 through the multi-layer stripping packing 3 to the top of the stripping section, and overflows through the top edge of the stripping sectio...

Embodiment approach 2

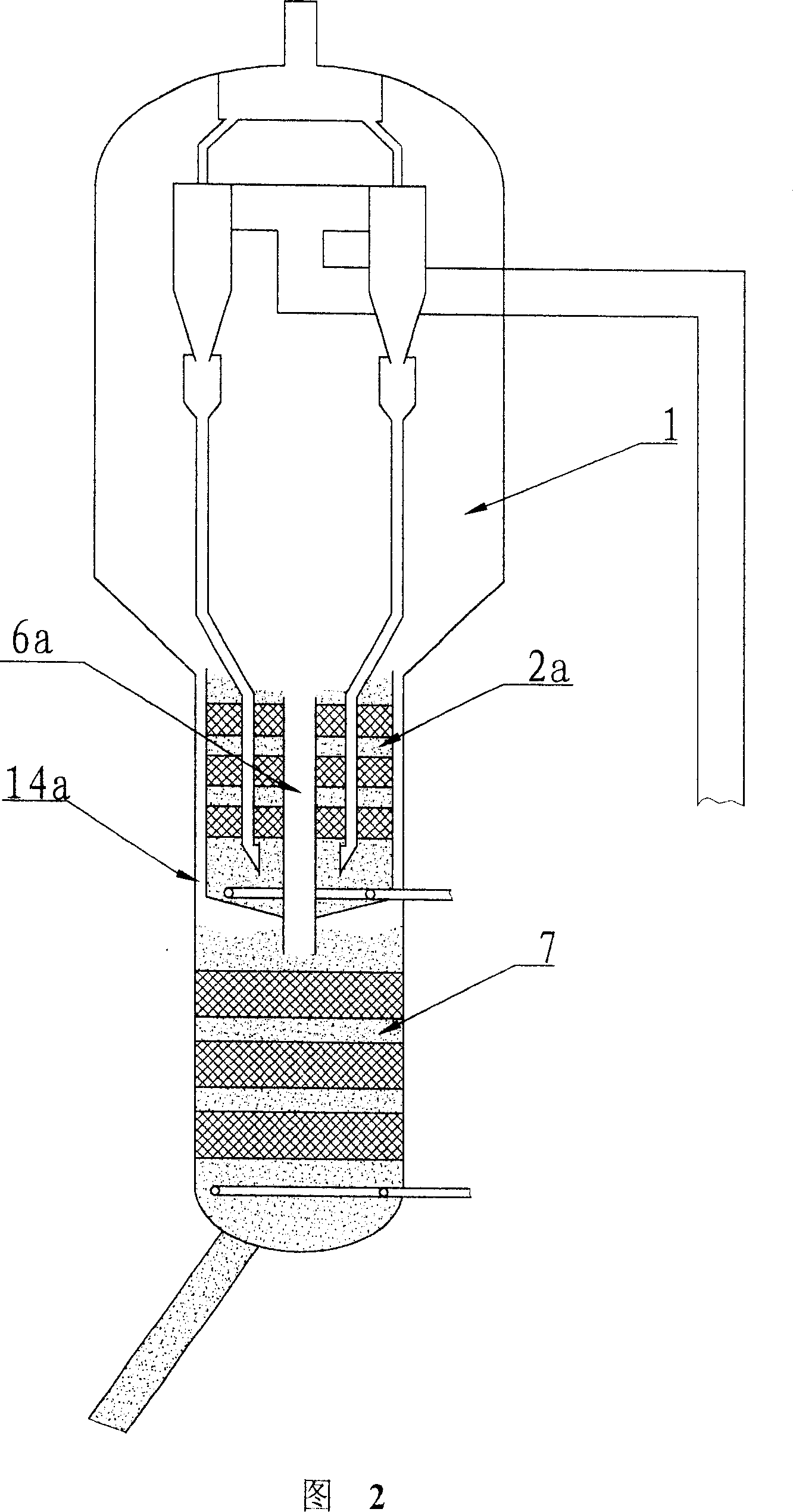

[0031] Embodiment two: as shown in Figure 2, this stripper comprises two stripper sections, and it differs from the stripper shown in Figure 1 in that: the catalyst that overflows through the first stripper section 2a is lowered by the center The feed pipe 6a enters the second stripping section 7, and the oil gas and stripping steam stripped from the second stripping section enters the dilute phase space of the settler 1 along the annular passage 14a. For realizing this purpose, the top outside edge of the first stripping section 2a will be 50-400mm higher than the top of the center lower feed pipe 6a, so just can guarantee that catalyst enters in the second stripping section from the center lower feed pipe, and Can not enter in the annular passage 14a that lifts up. Here the cross-sectional area of the central feeding pipe accounts for 5-20% of the stripper cross-sectional area, and the cross-sectional area of the annular channel accounts for 0.5-10% of the stripping cros...

Embodiment approach 3

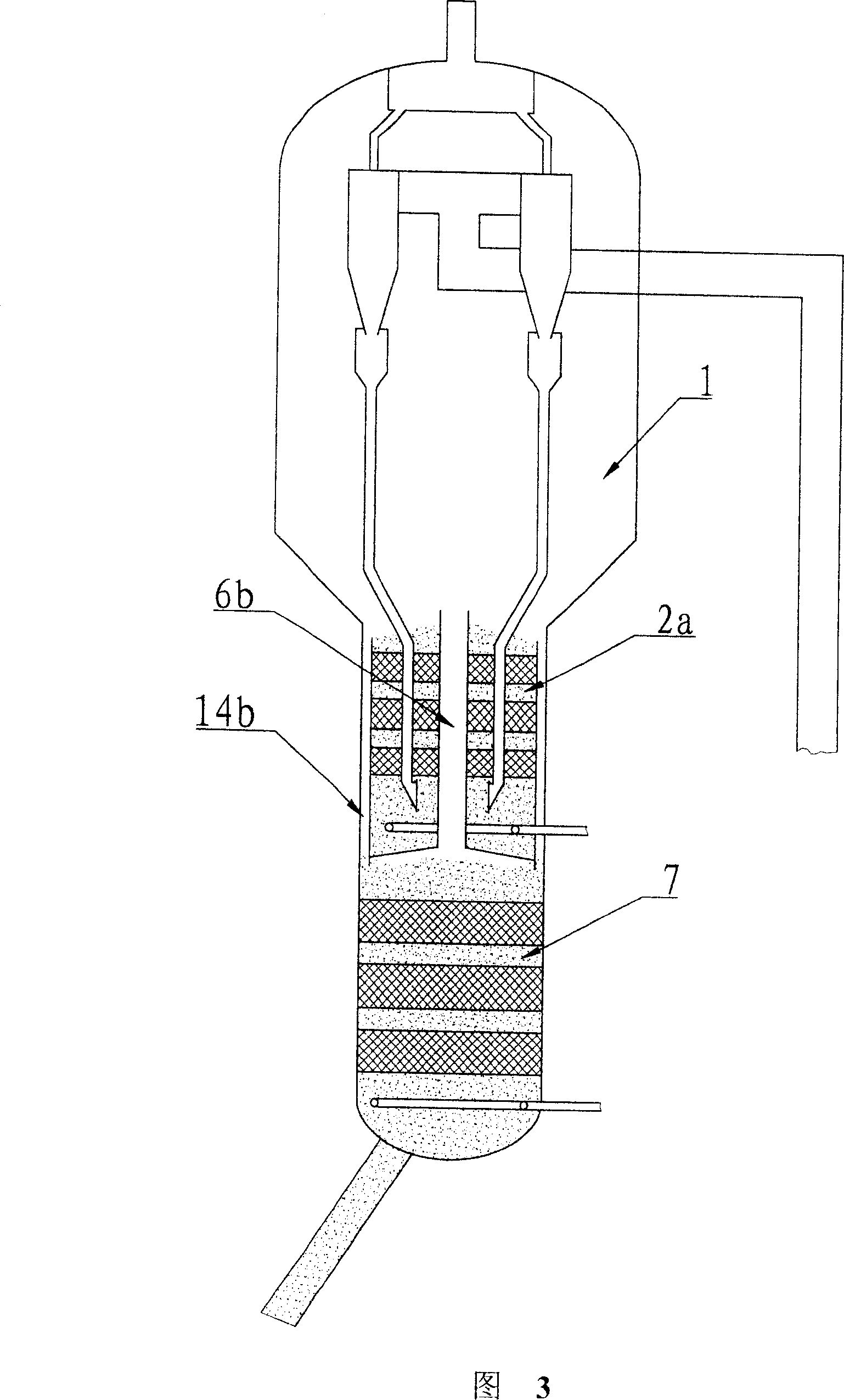

[0032] Embodiment three: as shown in Figure 3, the difference between this stripping method and the method shown in Figure 2 is: the catalyst that the first stripping section 2b overflows is overflowed by the top outside side wall of this stripping section The oil gas and stripping steam stripped from the second stripping section enter the dilute phase space of the settler 1 from the central riser 6b. For realizing this purpose, first stripping section 2b top outer edge will be 50-400mm lower than center gas riser 6b top, like this just can guarantee that catalyst enters in the second stripping section from the annular feeding channel 14b of side wall, And unlikely to enter in the central riser pipe. Here the cross-sectional area of the annular passage 14b accounts for 5-20% of the stripper cross-sectional area, and the bottom of the annular passage 14b will extend to the top of the second stripping section, and the cross-sectional area of the central air riser 6b accounts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com