Preparation process of barium strontium niobate ceramic powder

A technology of strontium barium niobate and ceramic powder, which is applied in the field of preparation of strontium barium niobate ceramic powder, can solve the problems of complex preparation process, influence on ceramic performance, long reaction cycle, etc., and achieve simple equipment, low cost, and low cost. The effect of synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

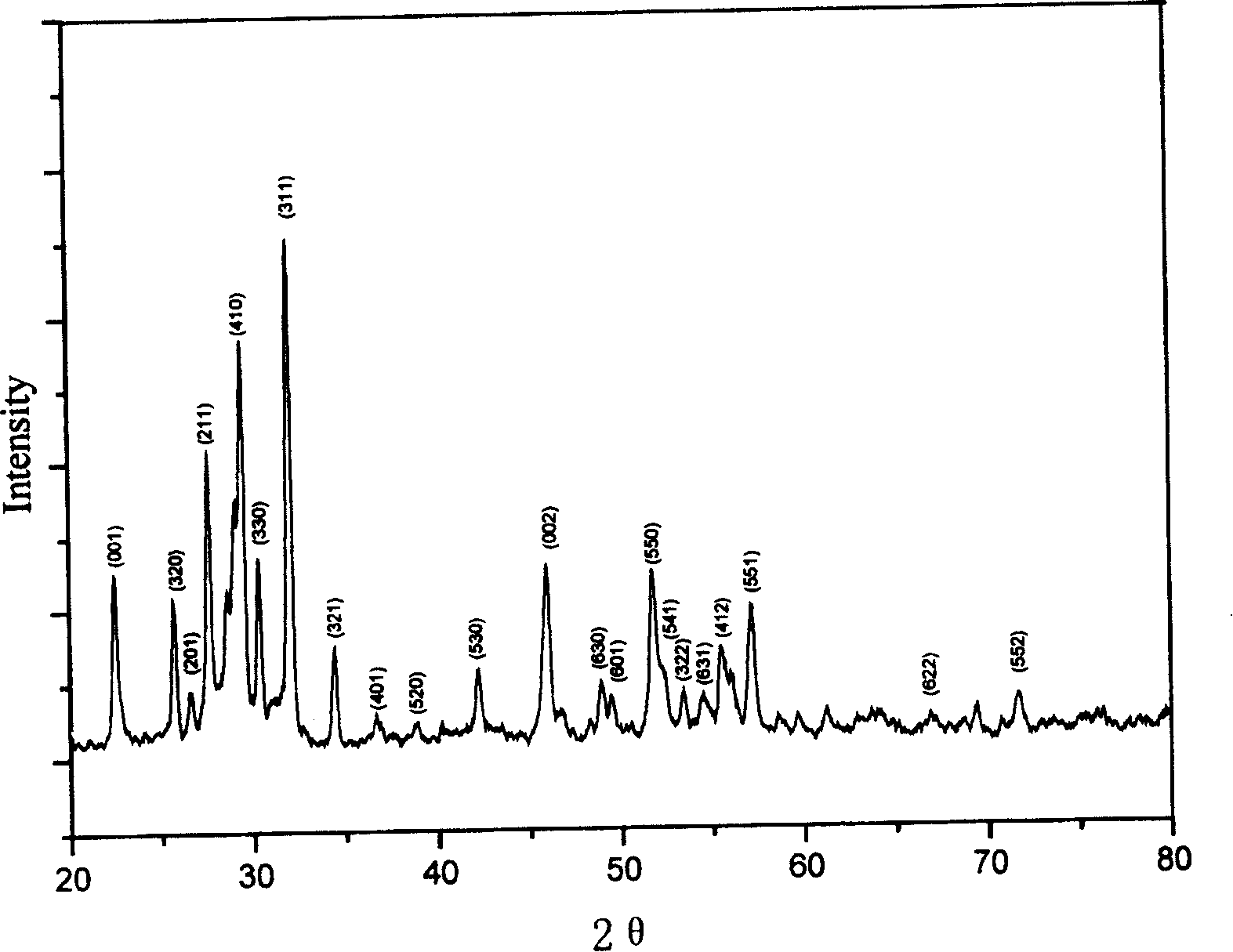

Embodiment 1

[0010] Embodiment 1: raw material adopts 0.1mol NbCl 5 (AR) reacts with 0.2mol primary distilled water, adding 0.25mol H 2 C 2 o 4 2H 2 O, add 2.19molH 2 o 2 (30%, v / w) as catalyst, stir well to obtain yellow transparent solution, add 0.0375mol Ba(NO 3 ) 2 (AR) and 0.0125mol Sr(NO 3 ) 2 (AR) as an oxidizing agent, add 0.014molC 6 h 8 o 7 ·H 2 O(AR) was used as a reducing agent to obtain a transparent yellow precursor solution. Pour the above precursor solution into an evaporating dish and heat it on an electric furnace to react to obtain a light yellow solid. This solid was roasted in a muffle furnace at 850°C. get Sr 0.25 Ba 0.75 Nb 2 o 6 Ceramic powder.

Embodiment 2

[0011] Embodiment 2: raw material adopts 0.1mol NbCl 5 (AR) reacts with 0.22mol primary distilled water, adding 0.25mol H2 C 2 o 4 2H 2 O, add 2.19molH 2 o 2 (30%, v / w) as catalyst, stir well to obtain yellow transparent solution, add 0.036mol Ba(NO 3 ) 2 (AR) and 0.014mol Sr(NO 3 ) 2 (AR) as an oxidizing agent, add 0.028molC 6 h 8 o 7 ·H 2 O(AR) as reducing agent, add 0.025mol NH 4 NO 3 (AR) is used as a combustion aid to obtain a transparent yellow precursor solution. Pour the above precursor solution into an evaporating dish and heat it on an electric furnace to react to obtain a light yellow solid. This solid is roasted in a muffle furnace at 850 ° C to obtain Sr 0.28 Ba 0.72 Nb 2 o 6 Ceramic powder.

Embodiment 3

[0012] Embodiment 3: raw material adopts 0.1mol NbCl 5 (AR) reacts with 0.24mol primary distilled water, adding 0.25mol H 2 C 2 o 4 2H 2 O, add 2.19molH 2 o 2 (30%, v / w) as catalyst, stir well to obtain yellow transparent solution, add 0.035mol Ba(NO 3 ) 2 (AR) and 0.015mol Sr(NO 3 ) 2 (AR) as an oxidizing agent, add 0.056molC 6 h 8 o 7 ·H 2 O(AR) as reducing agent, add 0.05mol NH 4 NO 3 (AR) is used as a combustion aid to obtain a transparent yellow precursor solution. Pour the above precursor solution into an evaporating dish and heat it on an electric furnace to react to obtain a light yellow solid. This solid is roasted in a muffle furnace at 850 ° C to obtain Sr 0.3 Ba 0.7 Nb 2 o 6 Ceramic powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com