Galantamin hydrobromide production method

A technology of galantamine hydrobromide and galantamine, applied in the direction of fermentation, etc., can solve the problems of incompatibility with high-quality requirements, low yield, and low galantamine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

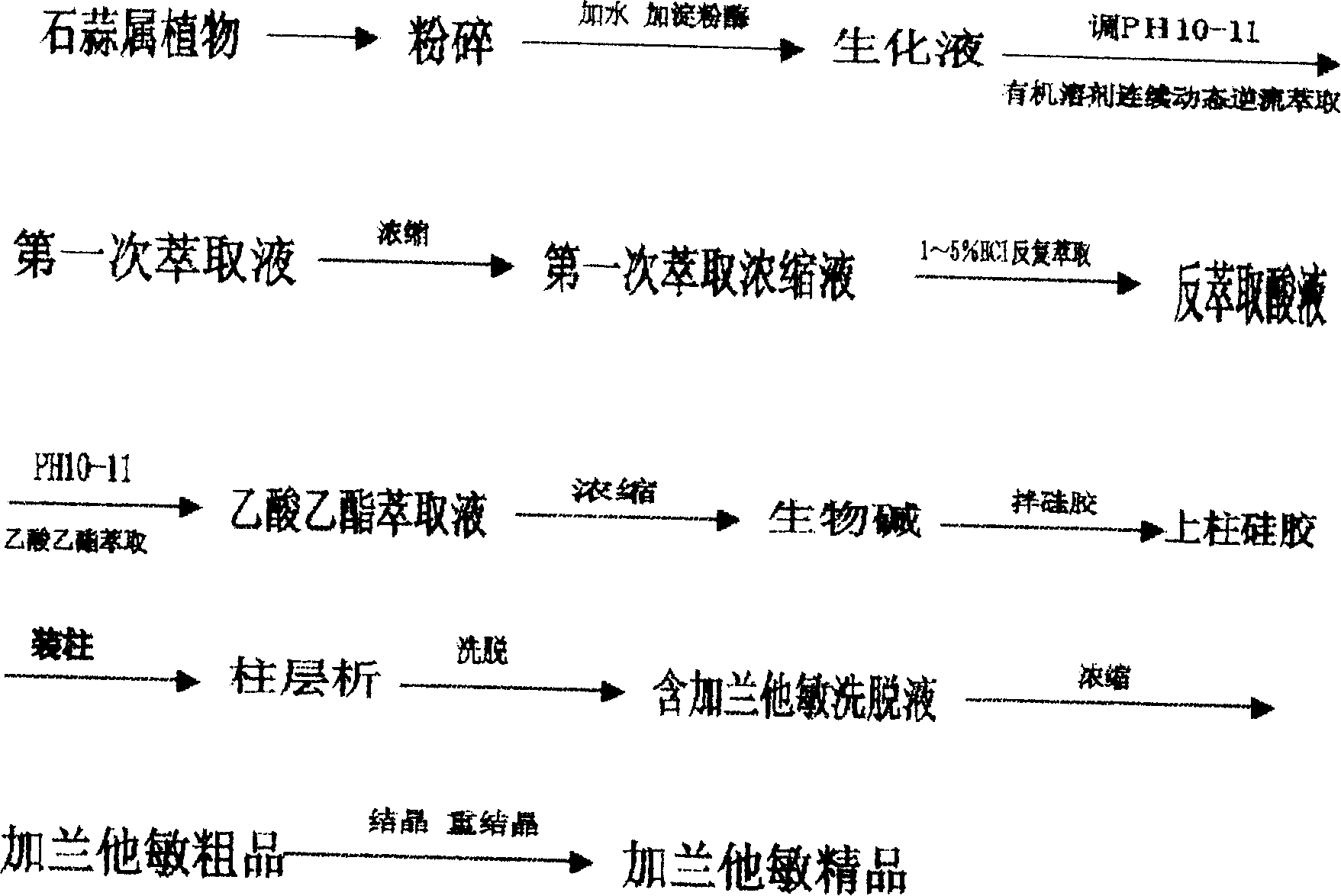

Method used

Image

Examples

Embodiment 1

[0066] Example 1. Add 200 kg of lycoris powder crushed to 80 meshes into the extraction equipment, add 800 kg of water, add 400 g of medium-temperature amylase, and hydrolyze it at 60°C for 2 hours to obtain a biochemical solution. Adjust the biochemical solution with 10% sodium hydroxide solution When the pH reaches 10, use a mixed solvent of petroleum ether ethyl acetate (petroleum ether: ethyl acetate = 9:1) to continuously and dynamically countercurrently extract the biochemical liquid until there is no galantamine in the extraction liquid at the overflow port of the extraction equipment, then concentrate and recover the solvent , 5 L of concentrated solution was obtained. Use 5L of 2% HCl solution to extract the concentrated solution for 5 times to obtain the stripping acid solution, add 10% NaOH to adjust the pH of the stripping acid solution to 10, use 25L ethyl acetate to extract the stripping acid solution for 5 times, and obtain the ethyl acetate extraction solution ...

Embodiment 2

[0067] Example 2: Add 200 kg of lycoris powder crushed to 80 meshes into the extraction equipment, add 1000 kg of water, add 500 g of medium-temperature amylase, and hydrolyze it at 60°C for 2 hours to obtain a biochemical solution, adjust the pH of the biochemical solution to 11 with 10% NaOH, and use Petroleum ether ethyl acetate (petroleum ether: ethyl acetate = 8: 2) mixed solvent for continuous dynamic countercurrent extraction of biochemical liquid until the extraction liquid at the overflow port of the extraction equipment has no galantamine, concentrate and recover the solvent to obtain 5.5 L of concentrated liquid . Use 5.5L of 5% HCL solution to extract the concentrated solution 5 times to obtain the stripping acid solution, add 10% NaOH to adjust the pH of the stripping acid solution to 10, extract with 30L ethyl acetate, and concentrate the ethyl acetate extract to dryness under reduced pressure to obtain 140 g of total alkaloids contained lycorine, saffronine, hom...

Embodiment 3

[0068] Example 3: Add 200 kg of lycoris powder crushed to 80 mesh in the extraction equipment, add 1200 kg of water, add 400 g of medium-temperature amylase, and hydrolyze it at 60°C for 2 hours to obtain a biochemical solution, adjust the pH to 10-11 with 10% NaOH, and use Petroleum ether ethyl acetate (petroleum ether: ethyl acetate = 9:1) mixed solvent for continuous dynamic countercurrent extraction of the biochemical liquid until the extraction liquid at the overflow port of the extraction equipment was free of galantamine, concentrated and recovered the solvent to obtain 6 L of concentrated liquid. Use 6L of 5% HCL solution to extract the concentrated solution for 5 times to obtain the stripping acid solution, add 10% NaOH to adjust the pH of the stripping acid solution to 10-11, extract the stripping acid solution with 30L ethyl acetate to obtain the ethyl acetate extract , the ethyl acetate extract was concentrated to dryness under reduced pressure to obtain 120 g of to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com