Main material of spraying film waterproofer with high extension strength and method for preparing the same

A spray film waterproof and tensile strength technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems that cannot fully meet the practical application requirements of underground engineering and the service life of magnesium acrylate waterproof materials , tensile strength and other mechanical properties decline, to achieve the effect of increased cross-linking points, enhanced force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

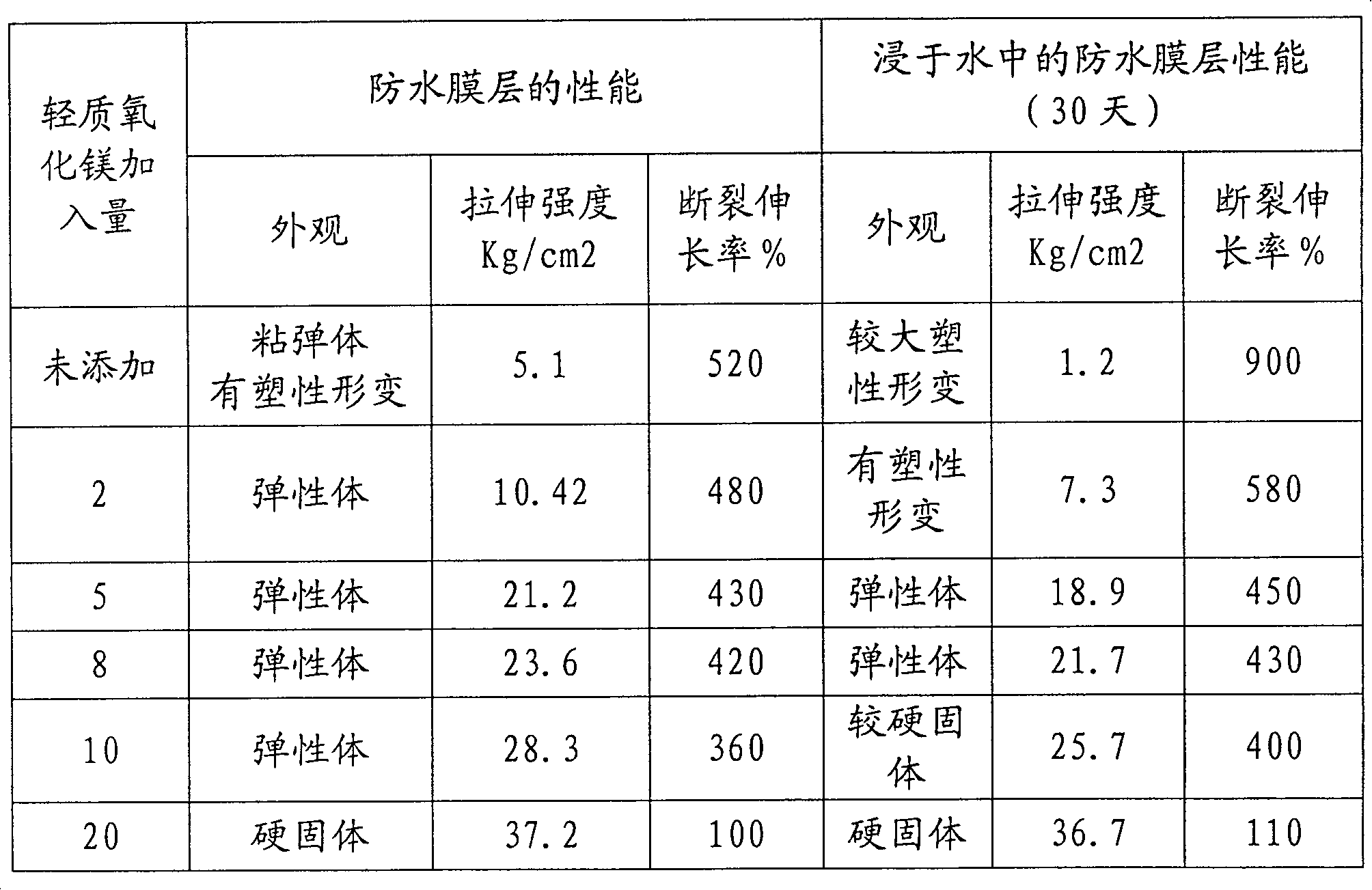

Examples

Embodiment 1

[0014] Add 1 part of light magnesium oxide with a particle size of 300 meshes to 100 parts of magnesium acrylate monomer aqueous solution; after mixing and soaking, then carry out high-speed stirring at 1500 rpm or more until there are no visible agglomerated particles in the solution, and this product is obtained. Example of spray film waterproof material main material.

Embodiment 2

[0016] The composition and preparation method of this example are basically the same as those of Example 1, except that 20 parts of light magnesium oxide is added, and the particle size is 600 mesh. Replace high-speed stirring with a ball mill until no agglomerated particles are visible in the solution.

Embodiment 3

[0018] This example is basically the same as Example 1, except that the added light magnesium oxide is 8 parts, and the particle size is 325 mesh. Replace high-speed stirring with a colloid mill until no agglomerated particles are visible in the solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com