Method of bacterial eliminating sulfur in high sulfur bauxite

A bauxite, high-sulfur technology, applied in the direction of bacteria, improvement of process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

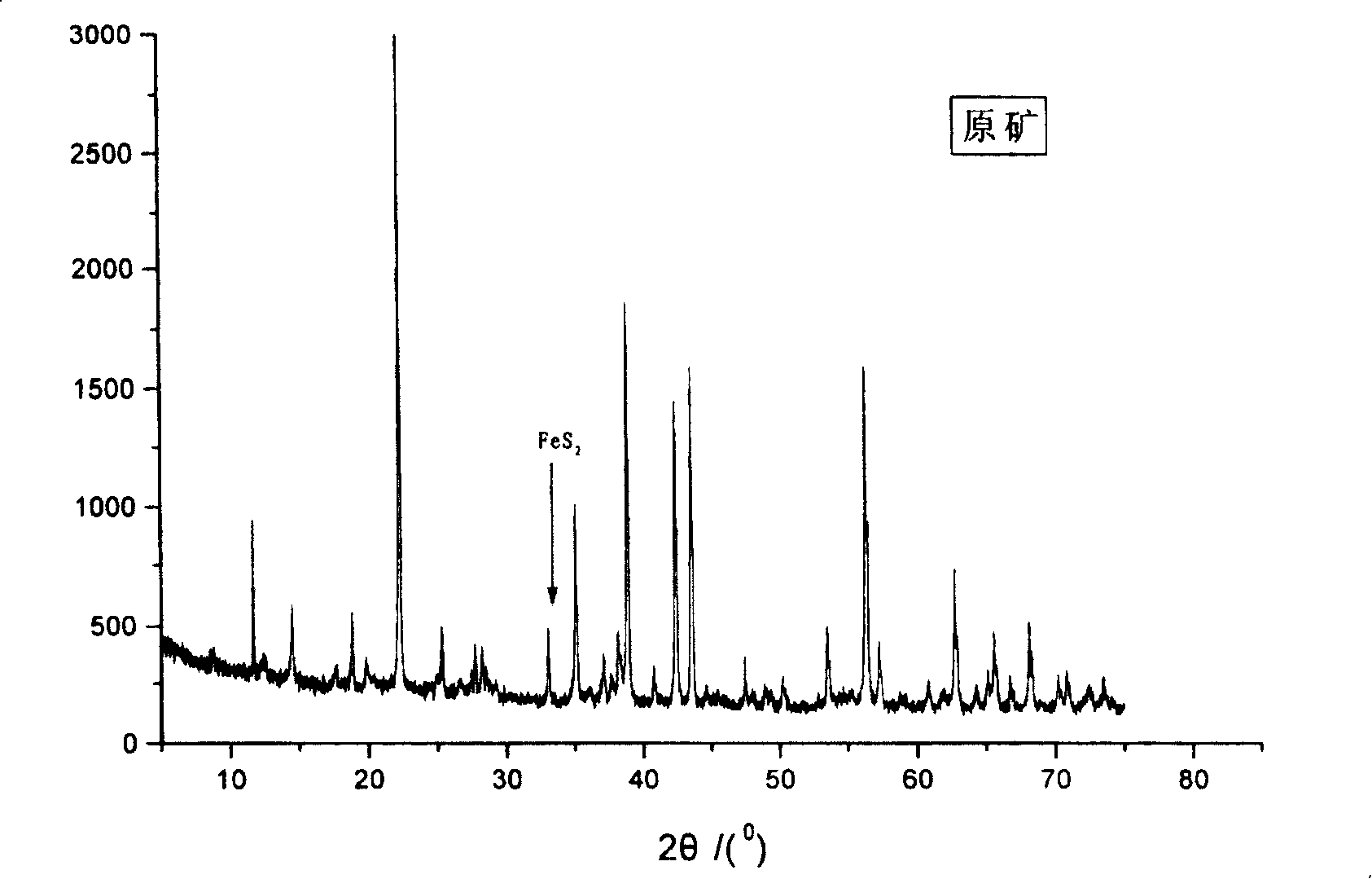

[0025] An enriched strain of Thiobacillus ferrooxidans with the ability to oxidize ferrous ions, elemental sulfur and sulfides was isolated from high-sulfur coal mine pit water, and the ferrous ion-free 9K medium (M9K - ) as the medium, and the high-sulfur bauxite with a sulfur content of 3.83% is used for domestication and cultivation, and the domestication process gradually increases the slurry concentration of the bauxite (1%, 2%, 5%, 10%) to obtain efficient Thiobacillus Mixed strains, the SEM image of the bacteria is shown in figure 1 .

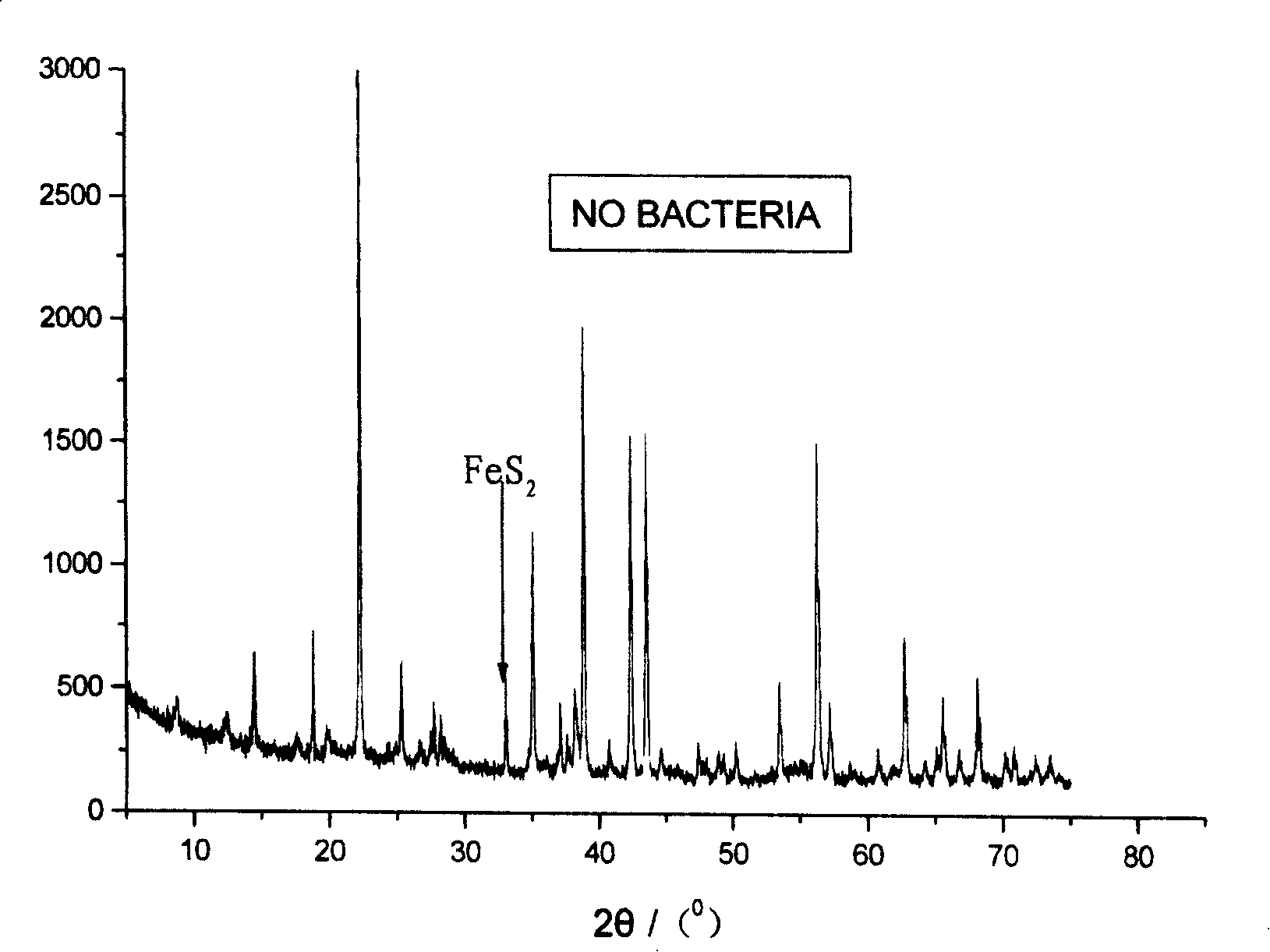

[0026] The enriched strain of Thiobacillus ferrooxidans obtained by screening and domestication is used for leaching of high-sulfur bauxite. The high-sulfur bauxite is crushed, and the particle size of the ore sample after fine grinding is less than 40 mesh. The leaching solution is prepared with tap water The 9K medium without ferrous ions does not need to be sterilized. Take the acclimatization culture solution and inoculate it in 9K...

Embodiment 2

[0030] Other conditions are the same as Example 1. The pH of the leaching system is 2.0, the rotating speed of the shaker is 250r / min, the leaching mineral sulfur content is 3.83%, the leaching temperature is 25°C, the inoculum size is 10%, and the pulp concentration is 10%. After leaching for 20 days, the mineral sulfur content is 0.55%, and the desulfurization rate is 86.96%. Al 2 o 3 The recovery rate is 97.21%.

Embodiment 3

[0032]Other conditions are the same as Example 1. The pH of the leaching system is 1.5, the rotating speed of the shaker is 150r / min, the leached mineral sulfur content is 3.83%, the leaching temperature is 30°C, the inoculum size is 10%, the mineral sulfur content after leaching for 15 days is 0.81%, the desulfurization rate is 80.97%, Al 2 o 3 The recovery rate is 92.49%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com