Ring-opening polymerization catalyst for lactide and process for preparing same

A ring-opening polymerization and catalyst technology, applied in the field of lactide ring-opening polymerization catalyst and its preparation, can solve the problems of high temperature, low activity, long time, etc., and achieve the effect of rapid stereoselective synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

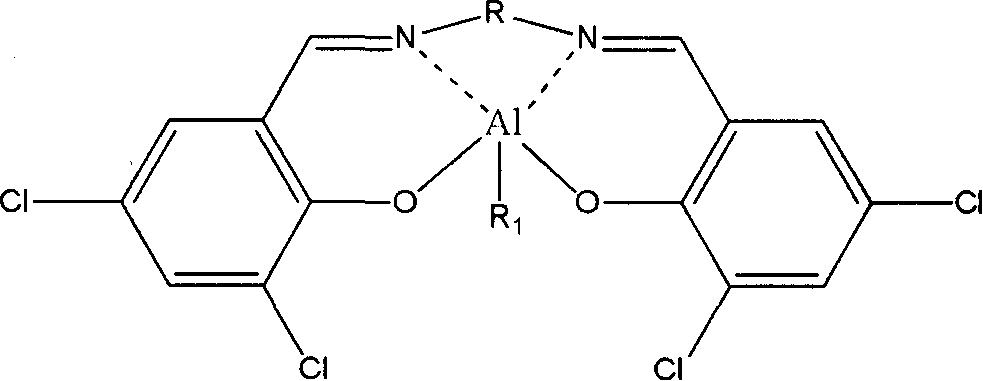

[0044] Synthesis and purification of 3,5-dichlorosalicylaldehyde ethylenediamineethylaluminum (Cat1a)

[0045] Dissolve 2.0 g of ethylenediamine in 5 ml of absolute ethanol, and 12.7 g of 3,5-dichlorosalicylaldehyde in 190 ml of absolute ethanol, wherein the molar ratio of ethylenediamine 3,5-dichlorosalicylaldehyde is 1:2. Slowly drop this ethylenediamine absolute ethanol solution into the stirred 3,5-dichlorosalicylaldehyde absolute ethanol solution at 80°C through a constant pressure funnel, and react for 0.5 hours to obtain 11.2 g of 3,5 -Dichlorosalicylaldehyde ethylenediamine ligand. 3g of 3,5-dichlorosalicylaldehyde ethylenediamine ligand was redissolved in 300ml of cyclohexane, heated to 100°C to dissolve completely, and then slowly lowered to room temperature to obtain 3,5-dichlorosalicylaldehyde ethyl Diamine ligand crystals.

[0046] Using anhydrous and oxygen-free technology, under the protection of argon, 1.0 g of purified 3,5-dichlorosalicylaldehyde ethylenedia...

Embodiment 2

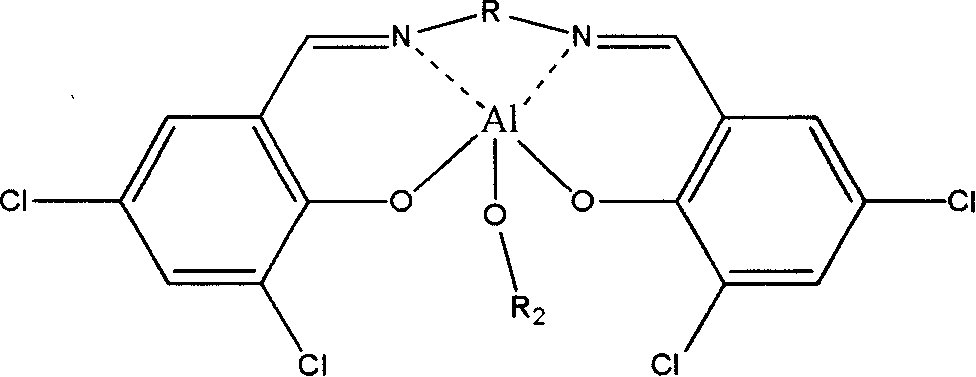

[0048] Synthesis and Purification of 3,5-Dichlorosalicylaldehyde Ethylenediamine Isopropoxy Aluminum Catalyst (Cat1b)

[0049] Using anhydrous and oxygen-free technology, under argon protection, 1.0 g of purified 3,5-dichlorosalicylaldehyde ethylenediamine ethylaluminum catalyst was dissolved in 5 ml of anhydrous toluene solvent, and 0.13 g of isopropanol was extracted. Add 2.6 ml of anhydrous toluene solvent to the stirred anhydrous toluene solution of 3,5-dichlorosalicylaldehyde ethylenediamine ethyl aluminum catalyst, heat up and reflux for reaction, and react at 80°C for 72 hours, then slowly lower the temperature to At room temperature, Cat1b was obtained.

Embodiment 3

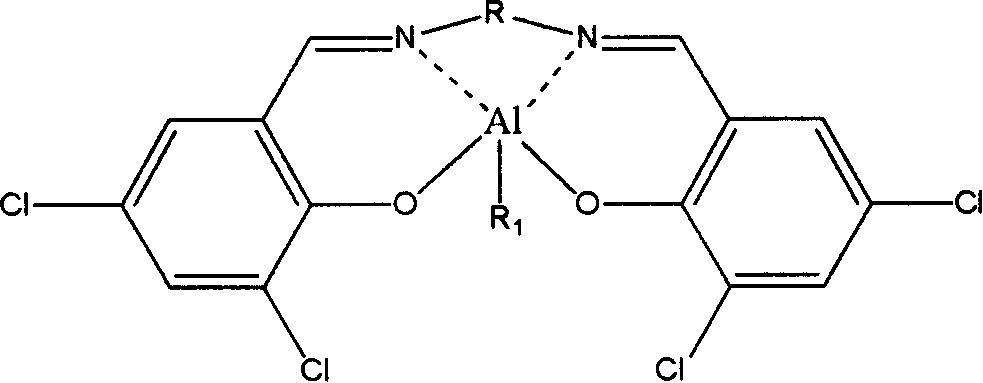

[0051] Synthesis and Purification of 3,5-Dichlorosalicylaldehyde Propylenediamine Methylaluminum Catalyst

[0052] Dissolve 2.5g of propylenediamine in 50ml of absolute ethanol, and dissolve 14.1g of 3,5-dichlorosalicylaldehyde in 1400ml of absolute ethanol, wherein the molar ratio of propylenediamine to 3,5-dichlorosalicylaldehyde is 1:2.2 . The absolute ethanol solution of propylenediamine was slowly added dropwise to the stirred 3,5-dichlorosalicylaldehyde absolute ethanol solution at 100°C through a constant pressure funnel, and reacted for 14 hours to obtain 14.9 g of 3,5- Dichlorosalicylaldehyde propylenediamine ligand. Redissolve 3g of 3,5-dichlorosalicylaldehyde propylenediamine ligand in 450ml of cyclohexane, raise the temperature to 85°C to dissolve it completely, and then slowly lower it to room temperature to obtain the purified 3,5 -Dichlorosalicylaldehyde propylenediamine ligand crystal.

[0053] Using anhydrous and oxygen-free technology, under argon protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com