Phase locking method of using outer cavity coherent of semiconductor laser coupled to optical fiber

A fiber coupling and semiconductor technology, applied in the field of external cavity coherent phase locking, can solve the problems of complex structure, inconvenient adjustment, large loss, etc., and achieve the effect of compact and simple structure, reduced optical loss, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

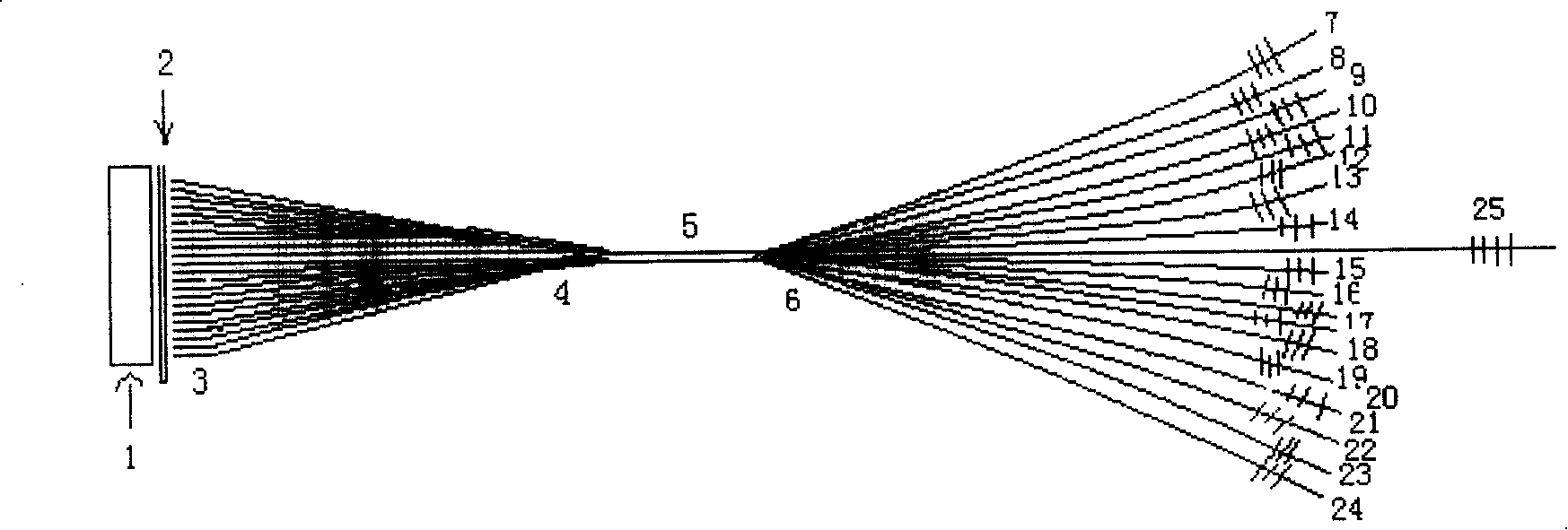

[0014] Example 1: figure 1 Shown is a first embodiment of the invention. Select a linear array of semiconductor lasers, wherein 19 light-emitting units are selected, and a focusing collimating lens 2 is installed at about 0.5mm in front of the light-emitting surface of the semiconductor laser 1, and the other side of the focusing collimating lens 2 is close to the focusing collimating lens. The output surface of the straight lens is one-to-one parallel to the light-emitting unit, and 19 optical fibers are bonded to form an optical fiber array 3, and then the other end of the optical fiber array 3 composed of 19 optical fibers pasted and coupled is bundled into an optical fiber bundle. The beam is directly fused into a large-diameter multi-film optical fiber 5, and the other end of the large-diameter multi-film optical fiber 5 is also fused with a 1×(18+1) multi-film optical fiber beam splitter 6, of which 18 output ends It is the auxiliary output terminal, and one is the main...

Embodiment 2

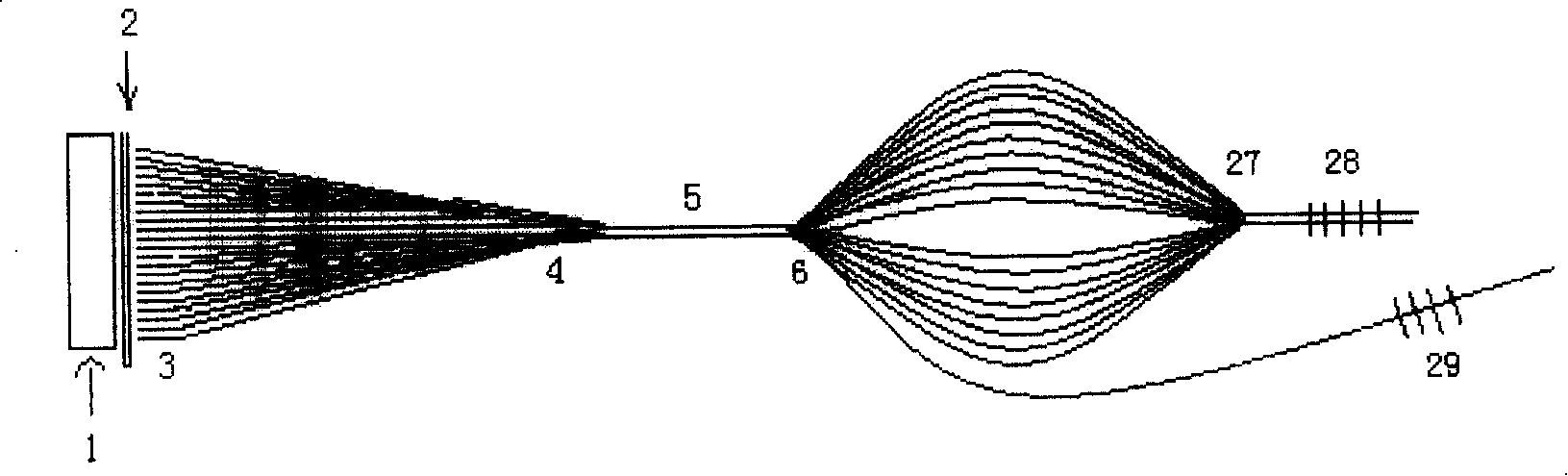

[0015] Example 2: figure 2 Shown is a second embodiment of the invention. Select a semiconductor laser linear array 1, wherein 19 light-emitting units are selected, and a focusing collimating lens 2 is installed at about 0.5mm in front of the light-emitting surface of the semiconductor laser 1, and the other side of the focusing collimating lens 2 is close to the focusing The output surface of the collimator lens is one-to-one parallel to the light-emitting unit, and 19 optical fibers are bonded to form an optical fiber array 3, and then the other end of the optical fiber array 3 composed of pasted and coupled 19 optical fibers is bundled into an optical fiber bundle. The fiber bundle is directly fused into a large-diameter multi-film optical fiber 5, and the other end of the large-diameter multi-film optical fiber 5 is also fused with a 1×(18+1) multi-film optical fiber beam splitter 6, of which 18 output The end is the auxiliary output end, and one is the main output end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com