Reinforced wood floor manufacturing method and reinforced wood floor

A technology for strengthening wood floors and steel plates, which is applied in the joining of wooden veneers, chemical instruments and methods, manufacturing tools, etc. Yield, reduce transfer and placement, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (embodiment 1, reinforced wood flooring)

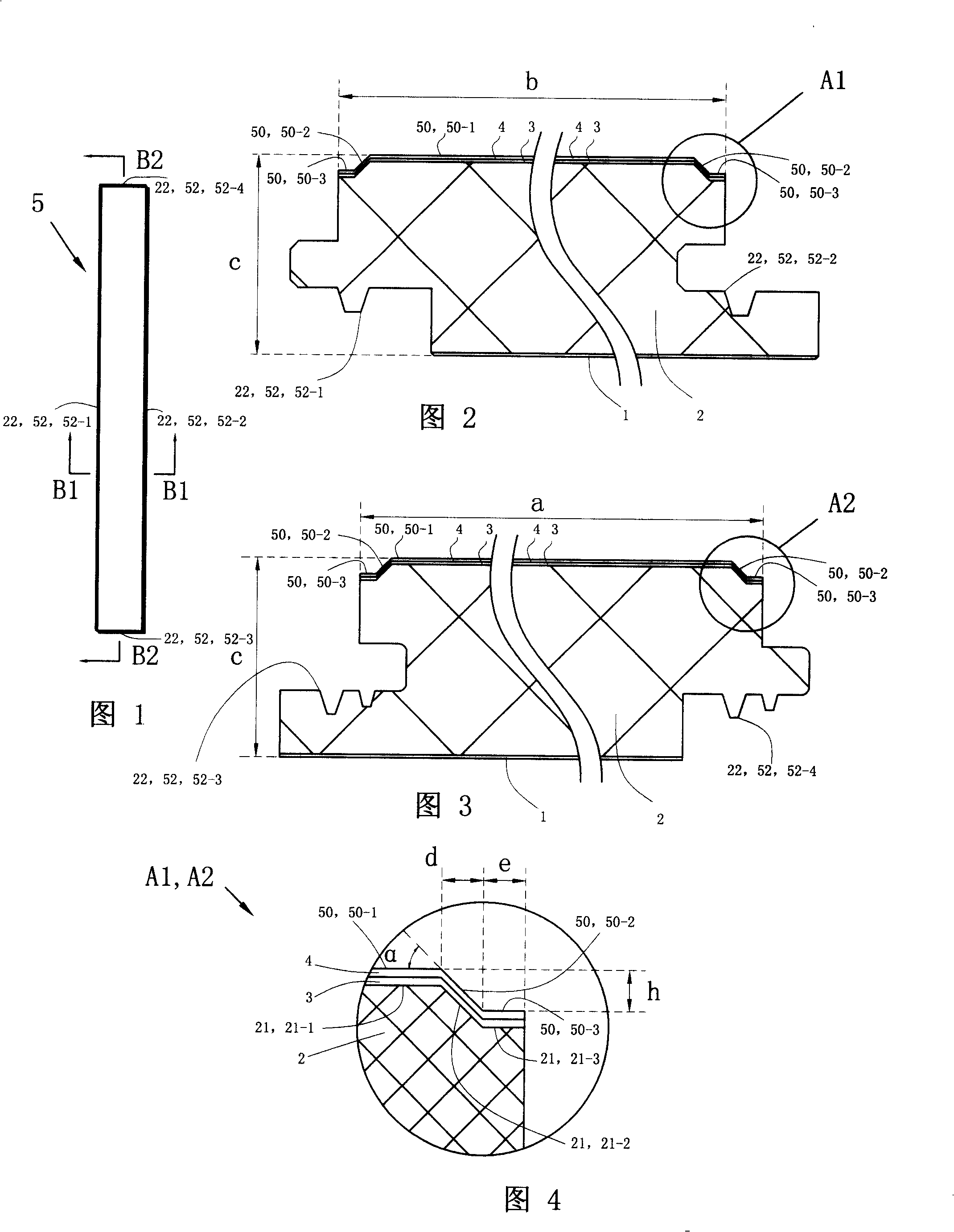

[0074]1 to 4, the heat-pressed laminate flooring 5 of this embodiment has a balance paper layer 1, a molded fiberboard body 2, a Textured paper layer 3 and wear-resistant paper layer 4, wherein balance paper layer 1, wood-grain paper layer 3 and wear-resistant paper layer 4 are all thermosetting layers bonded and fixed by thermocompression; molded fiberboard body 2 is high-density molded fiberboard body; the formed fiberboard body 2 has a fastening portion 22; the fastening portion 22 is composed of fastening parts arranged on four sides of the formed fiberboard body 2; the fastening portion 22 of the formed fiberboard body 2 is the hot-pressed laminate flooring 5 The fastening portion 52 of the molded fiberboard body 2 is a fastening tenon or a fastening groove seat; the lower surface of the balance paper layer 1 is the lower surface of the hot-pressed laminate flooring 5; wear-resistant The upper surface of the paper layer 4...

Embodiment 2

[0075] (Example 2, manufacturing method of laminate flooring)

[0076] Still see Fig. 1 to Fig. 4, the molded fiberboard body 2 in embodiment 1 uses high-density fiberboard as raw material plate, and the density of the high-density fiberboard 2 that it adopts is 900 kilograms per cubic meter, and the building decoration material market all has sales (In other embodiments, the molded fiberboard body 2 can also adopt a medium density fiberboard with a density of 600 to 800 kilograms per cubic meter as a raw material). The balance paper layer 1 adopts the melamine-impregnated balance paper distributed by Changzhou Bada Computer Room Equipment Co., Ltd. as the raw material paper, and its specification is 110 to 120 grams per square meter; It is prepared after processing steps such as dipping and drying of the glue solution. Wood grain paper layer 3 adopts melamine impregnated wood grain paper, which is called wood grain paper for short, manufactured by Zhejiang Wanli Decoration M...

Embodiment 3

[0095] (Example 3, manufacturing method of laminate flooring)

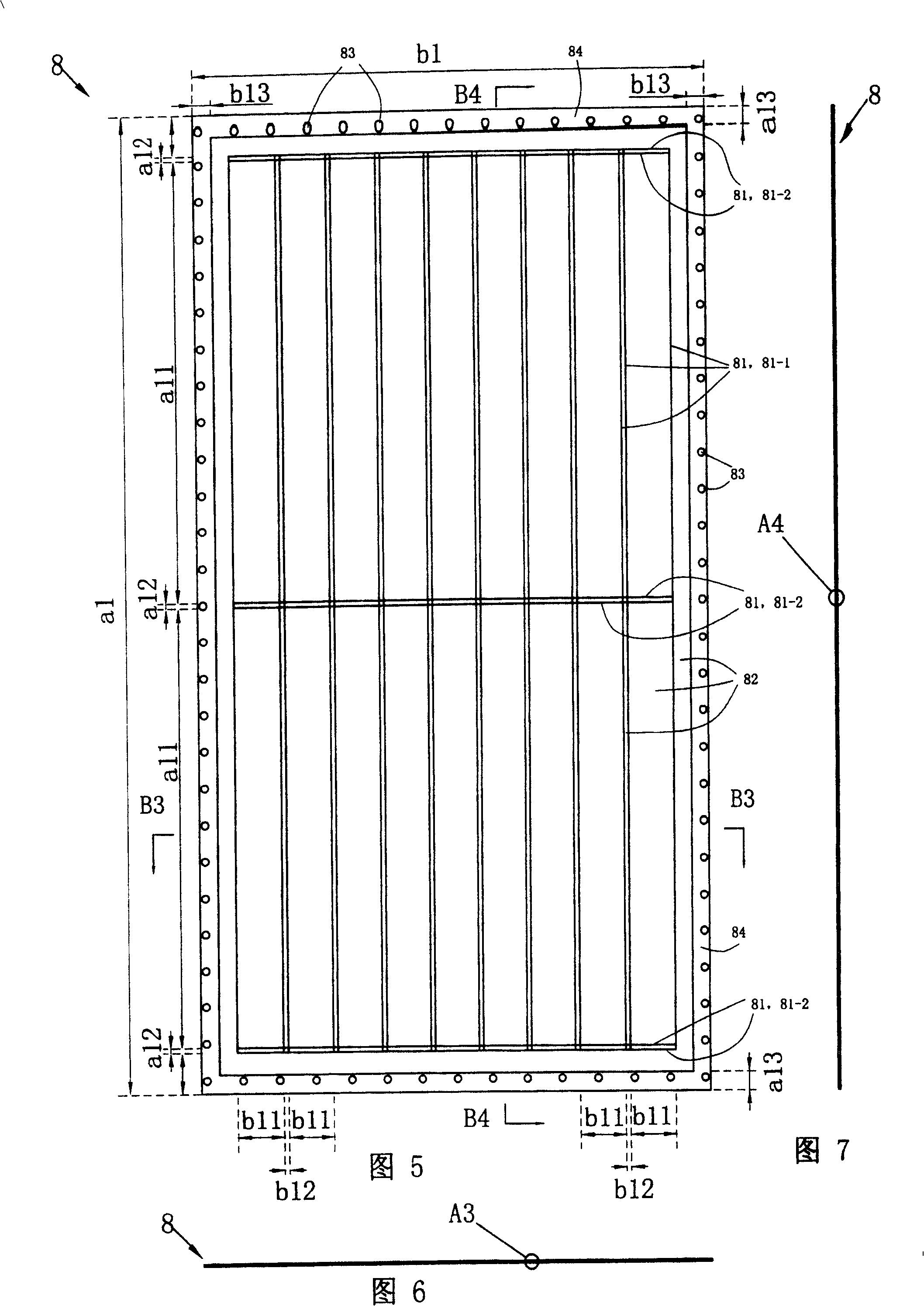

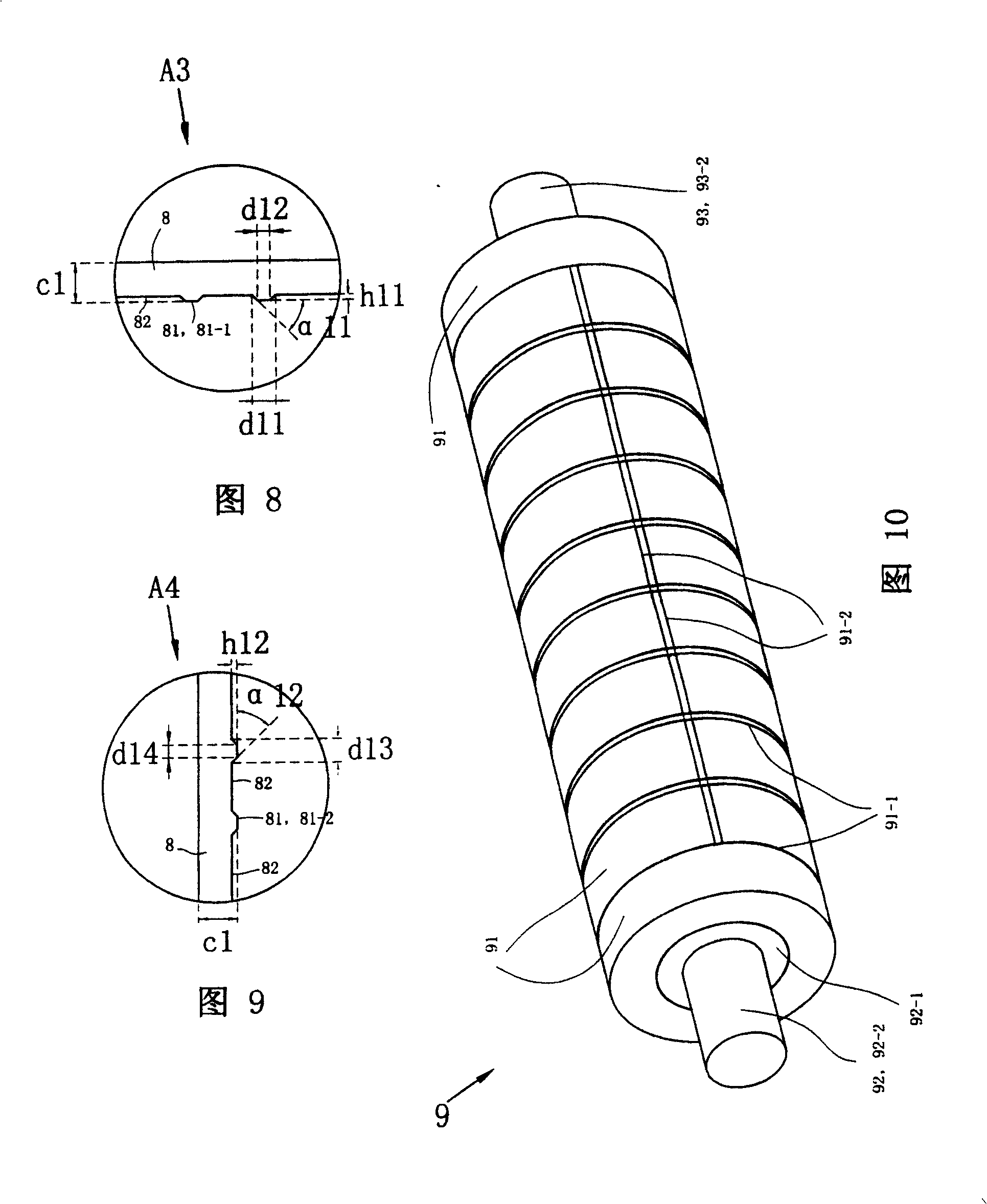

[0096] Referring to Fig. 1 to Fig. 27, all the other are basically the same as embodiment 2, the difference is that after the large piece 6 is formed by hot pressing, it is moved to the cooling rack, and the large piece 6 is air-cooled with a fan, so that the large piece 6 The temperature drops to a range greater than the indoor ambient temperature from 30°C to the indoor ambient temperature (65±2°C in this embodiment, other embodiments can be the indoor ambient temperature in the Chinese region, or 30±5°C); then use the saw board The processing equipment saws the large sheet 6 into a single piece of floor board 7 commonly known as "small sheet" of the desired size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com