Method for making high-temperature-resistance polyolefin microporous membrane

A technology for microporous membranes and manufacturing methods, which can be applied to flat products, applications, household appliances, etc., and can solve the problem of affecting the air permeability and mechanical strength of polyolefin microporous membranes, reducing the shrinkage rate of polyolefin microporous membranes, and blocking the ventilation of diaphragms. Performance and other issues, to achieve the effect of small heat shrinkage, small change in air permeability, and improved high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

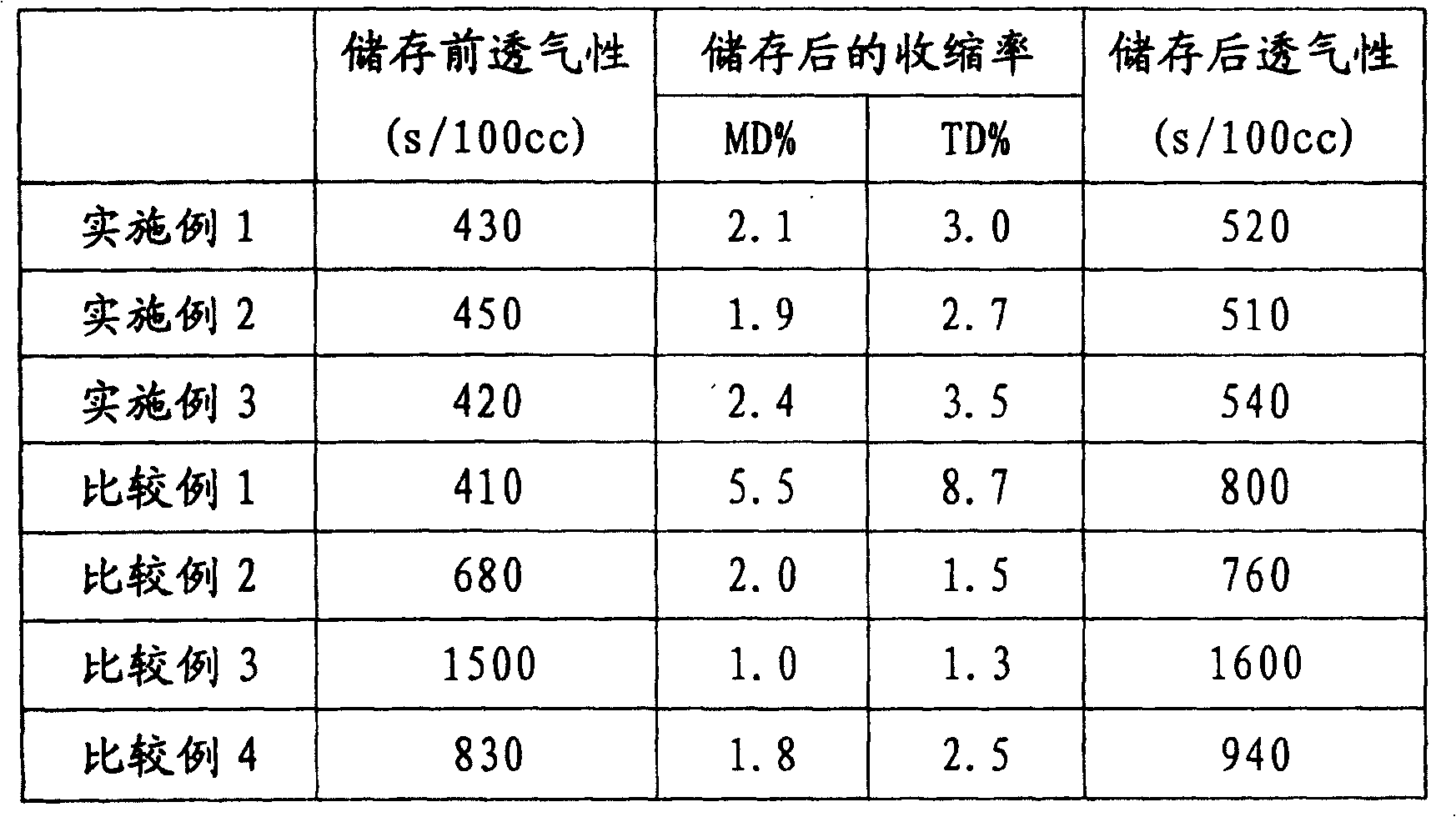

Examples

Embodiment 1

[0023] 27 (% by weight) of high-density polyethylene (weight-average molecular weight 2.7 × 10 5 , melting point 133 ° C), 3 (weight%) UHMWPE (ultra-high molecular weight polyethylene, weight average molecular weight 1.0 × 10 6 , melting point melting point 138 ℃) drop into twin-screw extruder (diameter 78mm, L / D=48, strong mixing type), add 70 (weight %) liquid paraffin (kinematic viscosity) by side feeding port with metering pump 90cst / 40°C), melted and kneaded under the conditions of 200°C and 200 rpm to prepare a polyethylene solution.

[0024] Pass the polyethylene solution through a T-shaped die (die lip opening 1.2 mm, width 260 mm), extrude at a speed of 3 m / min, and cool the cast sheet on a casting roll with a surface temperature of 10 ° C to obtain a 1.0 mm thick Thick slices.

[0025] Stepwise biaxially stretch the thick sheet, and the stretch ratio is vertical × horizontal = 5 × 7 times, wherein the preheating temperature for longitudinal stretching is 115°C, and...

Embodiment 2

[0029] In the heat treatment step, the heat treatment temperature is 130° C., and the treatment time is 5 seconds. Other steps are the same as in Example 1.

Embodiment 3

[0031] In the heat treatment step, the heat treatment temperature is 125° C., and the treatment time is 12 seconds. Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com