Semiconductor end-electrode structure and its making method

A manufacturing method and terminal electrode technology, which are used in semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve problems such as low hardness of gold bumps, shorten annealing time, improve hardness, and improve brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

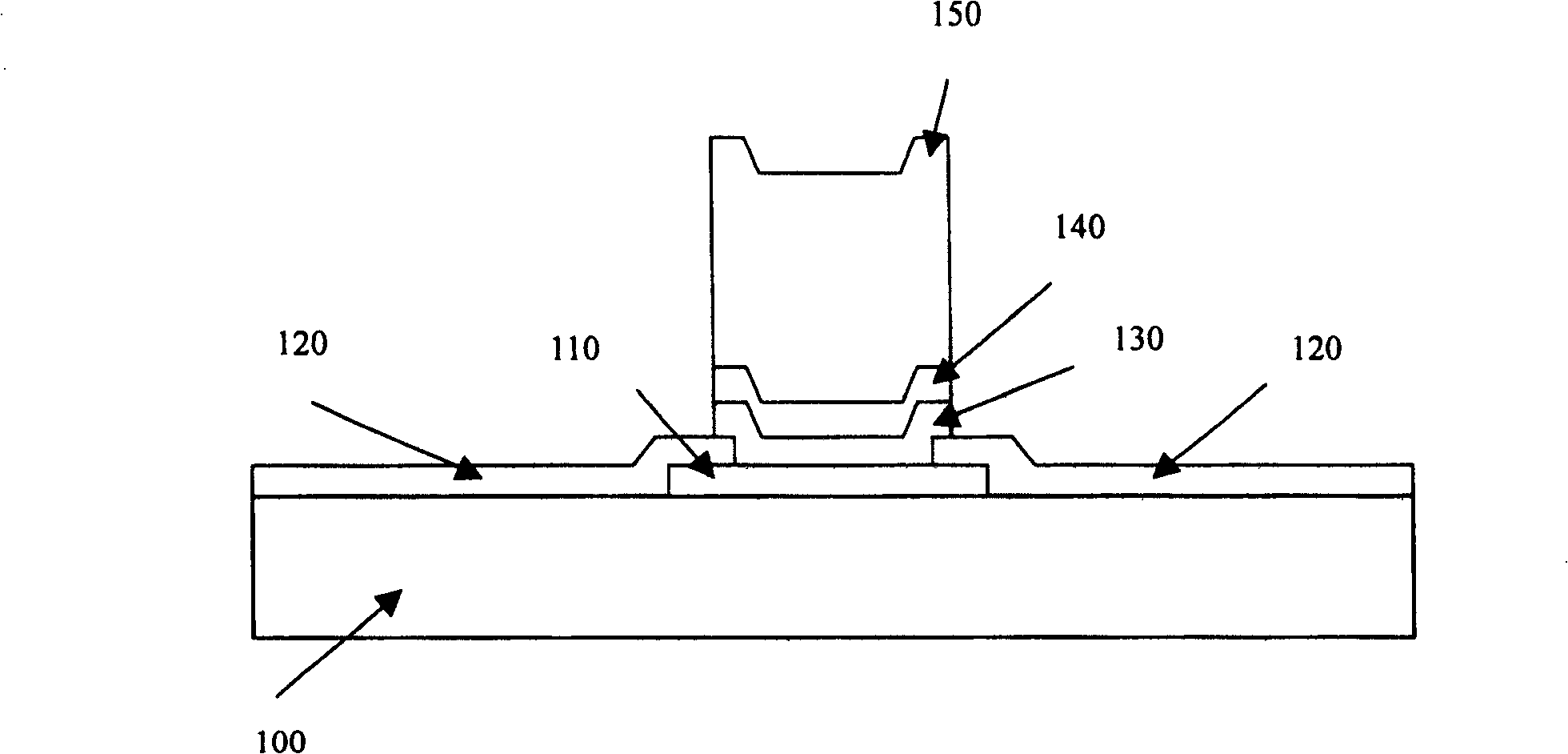

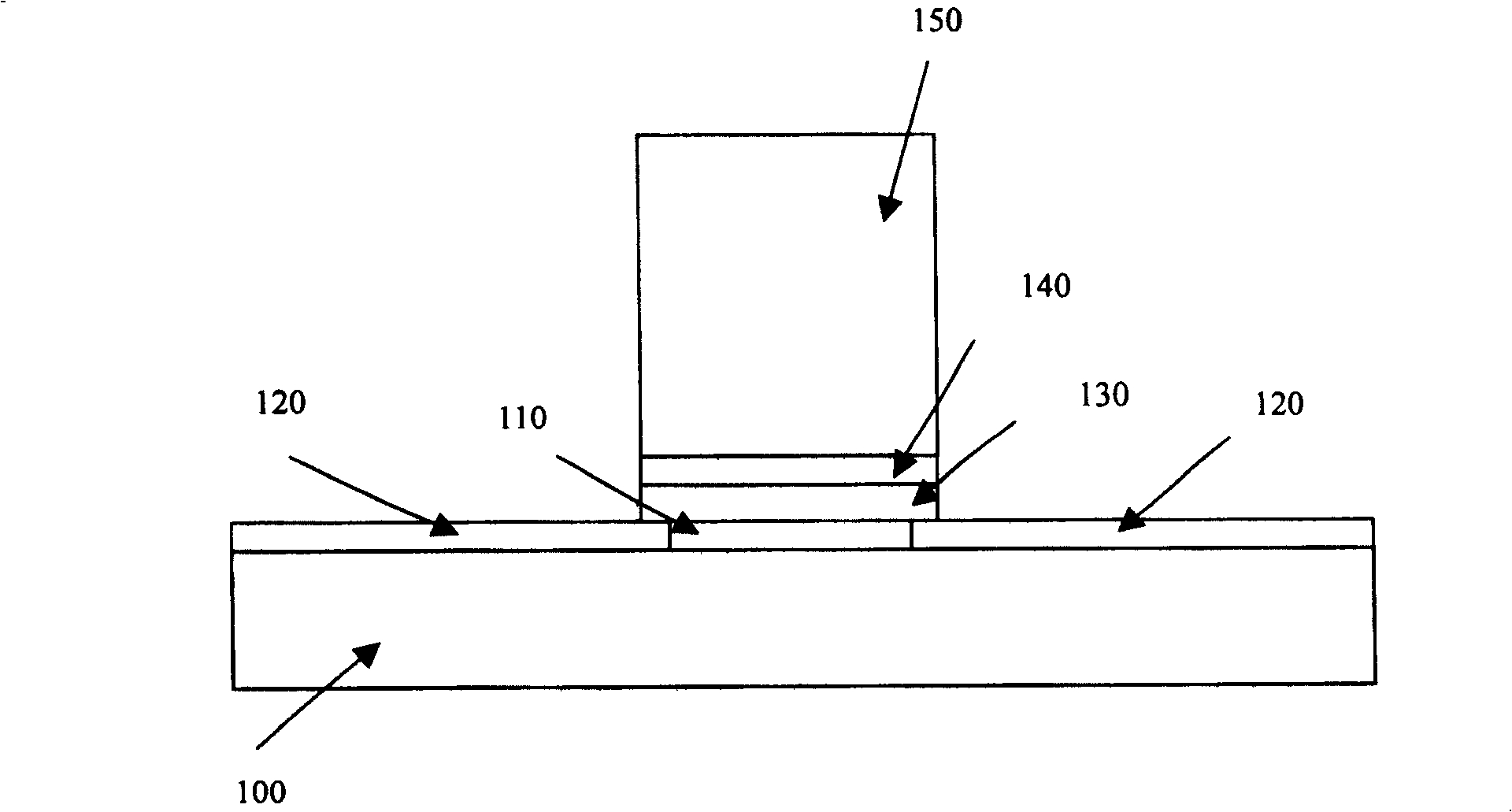

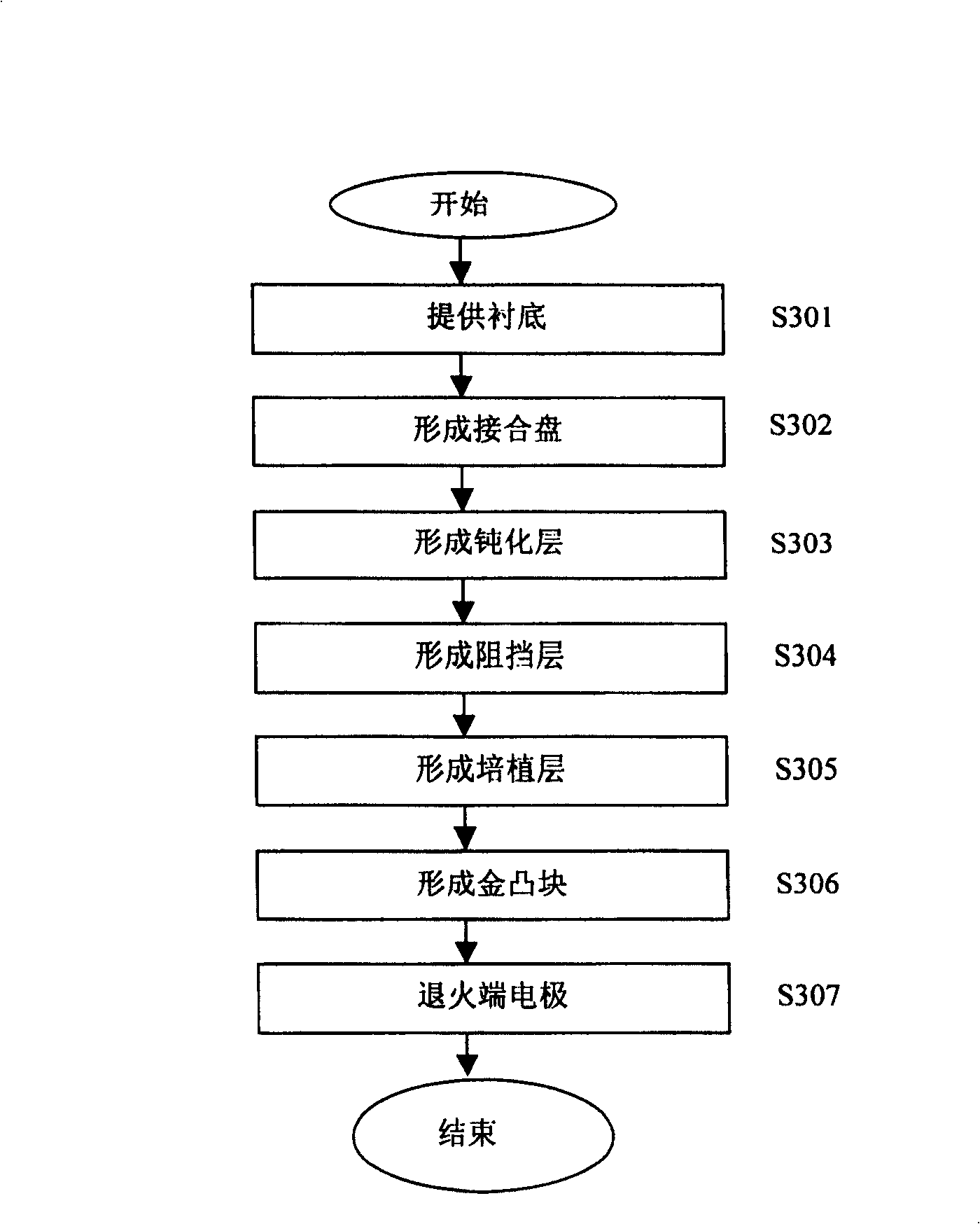

[0035] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] The semiconductor terminal electrode structure and the manufacturing method thereof of the present invention improve the hardness of the gold bump without sacrificing the purity of the gold. In the preferred embodiment of the present invention, annealing is stopped at 145°C instead of annealing at room temperature, a small amount of metal thallium is added during the process of electroplating gold bumps, and its concentration is controlled within the range of 18-28ppm. A barrier layer composed of titanium-tungsten alloy is formed on the disk, and an implantation layer composed of gold is formed on the barrier layer, and gold bumps containing a very small amount of thallium are electroplated on the implantation layer.

[0037] figure 1 It is a schematic diagram of an embodiment of the semiconductor terminal electrode structure of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com