An even low-shearing self-absorbing emulsion droplet preparation device

A preparation device and low-shear technology, which is applied in the field of uniform low-shear self-priming emulsion droplet preparation device, can solve the problem of low uniformity of emulsion droplet size, unstable emulsion system, and large difference in emulsion droplet size and other problems to achieve the effect of solving the uneven particle size of emulsion droplets and avoiding excessive local shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1. Preparation of polylactic acid microspheres with uniform particle size by self-priming emulsion droplet preparation device on uniform low shear

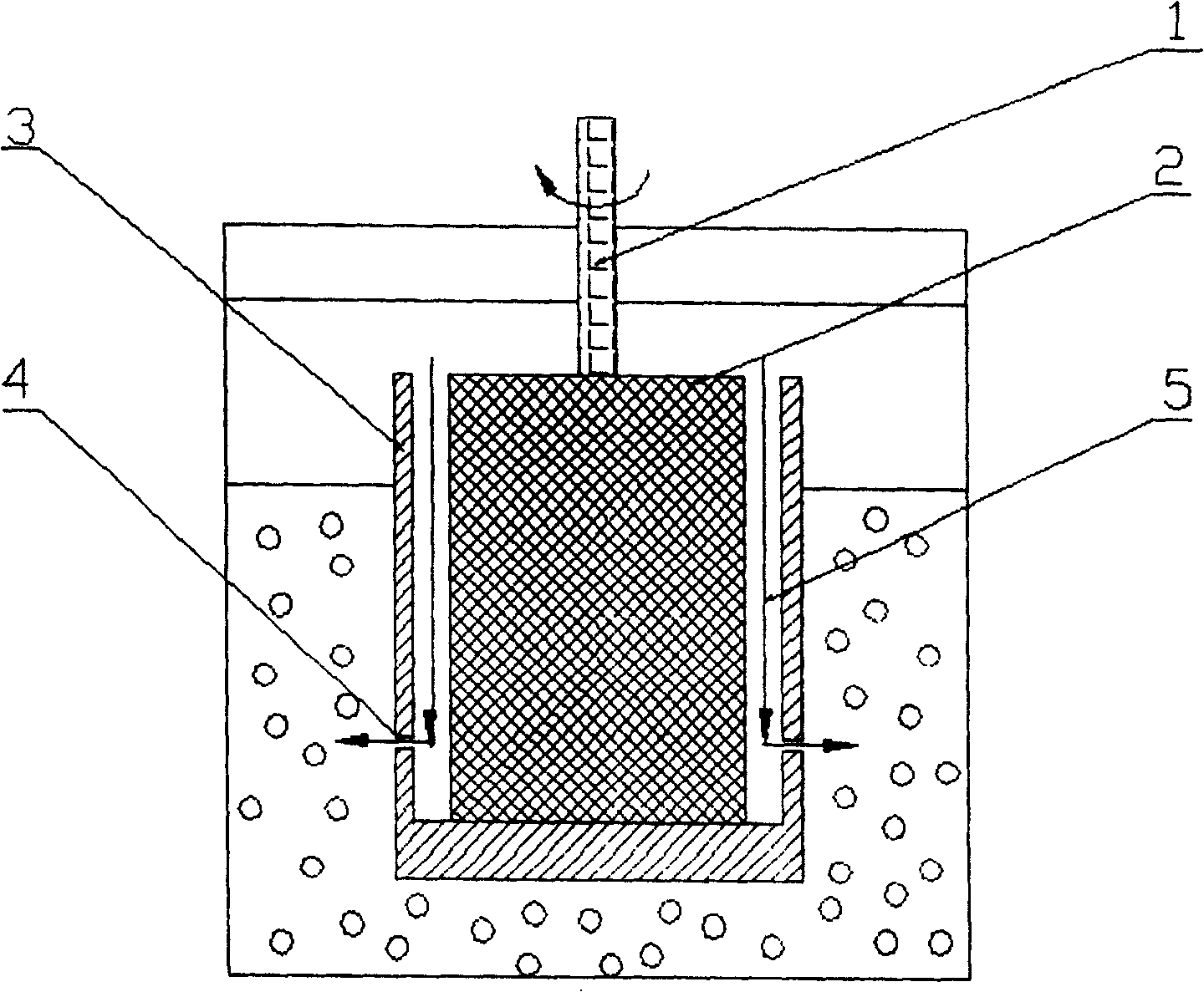

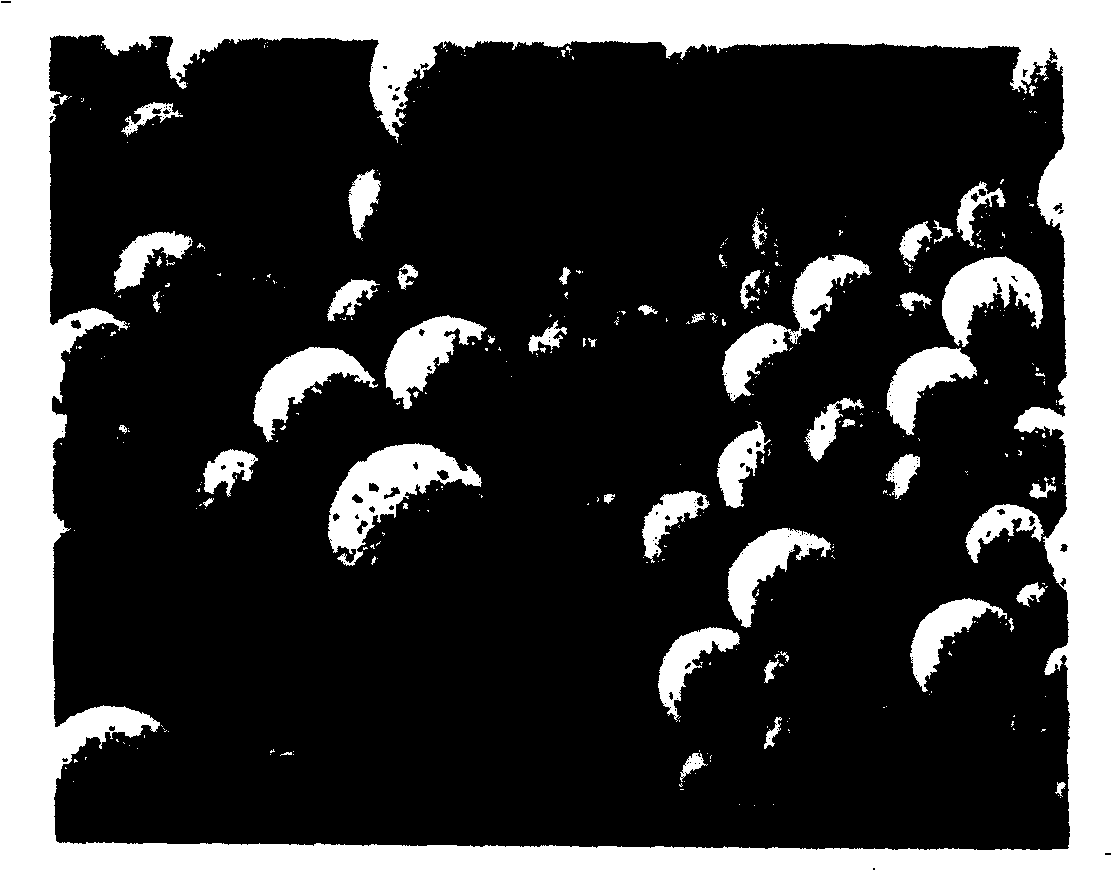

[0027] Pour 80 mL of 2.0 wt % polyvinyl alcohol (PVA) deionized aqueous solution (water phase) and 10 mL of ethyl acetate (oil phase, density of the oil phase less than 1.0 g / mL) dissolved with 500 mg of polylactic acid into a 150 mL beaker. Respectively adopt conventional anchor type mechanical stirring device, self-priming multi-channel phase dispersion extraction device (Chinese Patent Publication No. CN1318422A, disclosure date on October 24, 2001), figure 1 The shown homogeneous low-shear upward self-priming emulsion droplet preparation device (the hole diameter of the outlet is 2mm) prepares oil / water emulsion (disperse the light phase into the heavy phase) under the same conditions. The rotation speed of the driving motor was 300 rpm, and the mixture was stirred for 3 minutes. Then pour it into a 300mL conic...

Embodiment 2

[0029] Example 2. Preparation of polylactic acid microspheres with uniform particle size by self-priming emulsion droplet preparation device under uniform low shear

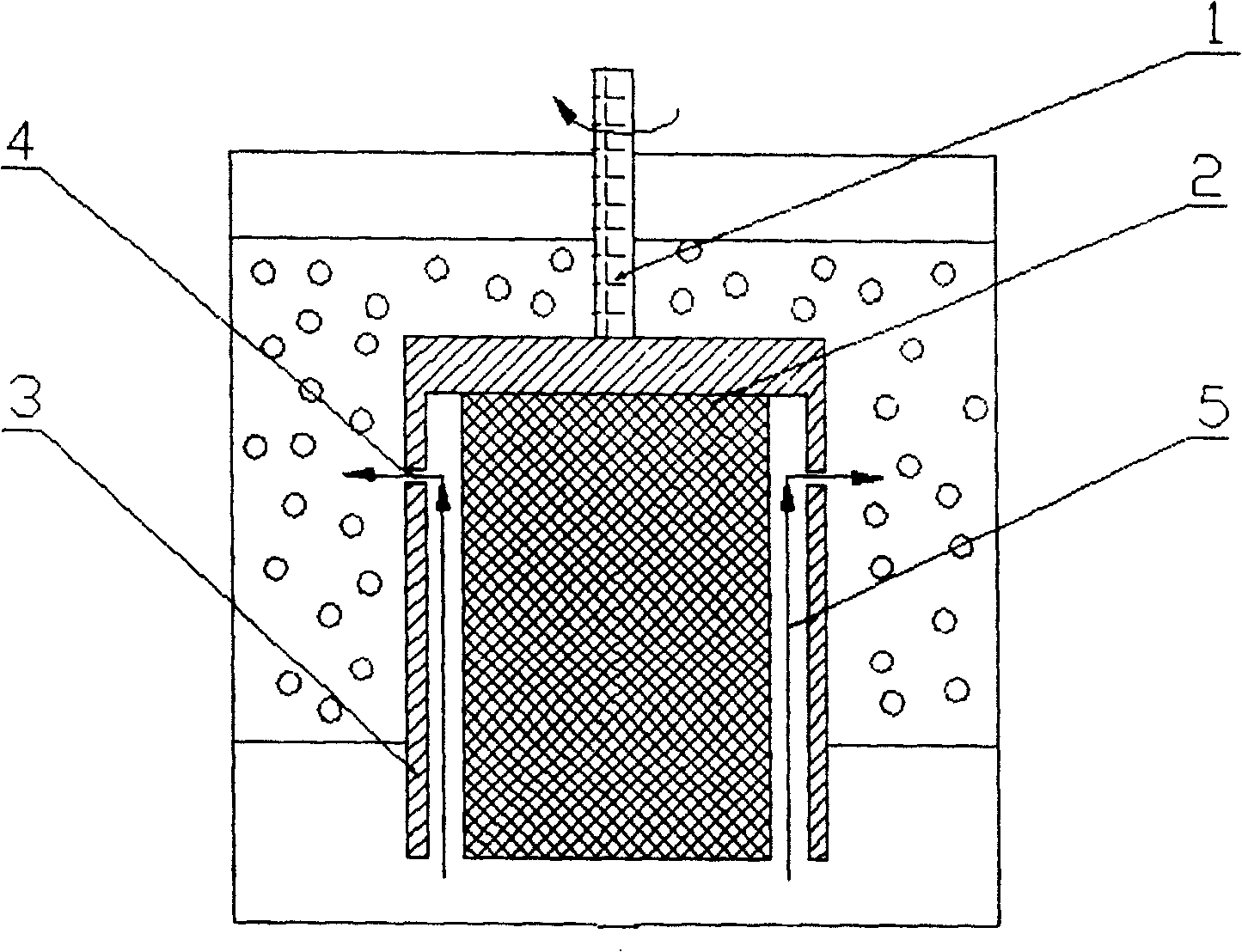

[0030] Pour 80mL of 2.0wt% polyvinyl alcohol (PVA) deionized aqueous solution (water phase) and 10mL oil phase into a 150mL beaker, and the oil phase is a mixed solution of dichloromethane and toluene dissolved with 500mg polylactic acid (by controlling both ratio to adjust the density of the oil phase to be greater than 1.0 g / mL). Respectively adopt self-priming multi-channel phase dispersion extraction device (Chinese Patent Publication No. CN1318422A, open date on October 24th, 2001) and figure 2The shown self-priming emulsion drop preparation device under uniform low shear (the hole diameter of the outlet is 2mm) prepares an oil / water emulsion (disperse the heavy phase into the light phase) under the same conditions. The rotation speed of the driving motor was 300 rpm, and the mixture was stirred for 3 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com