Polyurethane fibre/real silk crepe knit fabric and preparation process thereof

A technology of spandex and real silk, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems affecting the wearability of fabrics, the spandex yarn is easy to break, and the dyeing uniformity and color fastness of fabrics are affected. It is easy to promote Small deformability and good elasticity during use and washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The process step that present embodiment adopts is:

[0021] Raw materials, winding, twisting, rewinding, knitted fabric weaving, pretreatment, dyeing, creping, drying, finishing, finished products.

[0022] 1. Raw material: The raw material of this embodiment selects a real silk-coated spandex yarn with a linear density of 20-25 denier side-by-side silk spandex-coated yarn, and the twist is 50-100 twists / meter.

[0023] 2. Winding: according to the conventional process of silk winding;

[0024] 3. Twisting: according to the existing routine process of silk twisting;

[0025] 4. Rewinding: according to the existing routine process of silk rewinding;

[0026] 5. Weaving: Weaving is carried out on a large circular knitting machine;

[0027] 6. Pretreatment: Scouring treatment is carried out on a silk scouring machine or a low-tension rope overflow machine. The purpose is to remove impurities such as oil and sericin on real silk knitted fabrics, improve the wool effect ...

Embodiment 2

[0036] The raw materials are two silk-coated spandex yarns, each spandex / silk-coated yarn has a linear density of 40-45 denier, and the twist of the wrapped spandex / silk-coated yarn is 1000-1500 twists / m. In the previous processing, two yarns are used to weave silk knitted fabrics on a knitting machine.

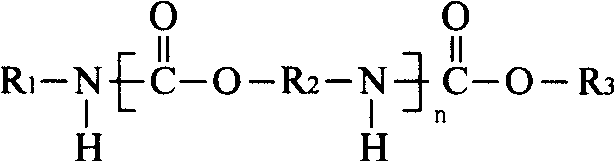

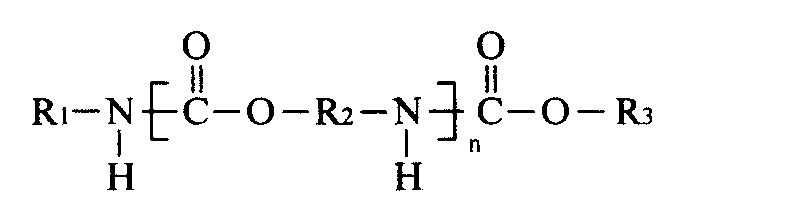

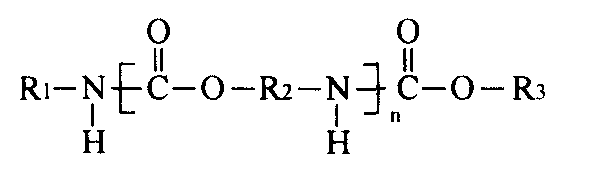

[0037] The printing and dyeing process includes scouring, dyeing, creping, finishing and other processes. The scouring process conditions are: scouring temperature 95-115°C, time 60-120 minutes, bath ratio 1:25-50, rapid scouring agent (such as AR-617) 3-10g / L, soda ash 3-10g / L. The one-step dyeing and creping process conditions are: 2% acid dye, use acetic acid or acetic acid / sodium acetate to adjust the pH of the dye solution to 4-5.5, 5% hydrophilic carbamate polymer, hydrophilic polypeptide protein The polymer is the hydrolyzate of silk fibroin protein with a concentration of 0.5%, the bath ratio is 1:15-30, the temperature is 90-120°C, and the time is 60-120 minutes. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com