Preparation method of reflection circularly polarized light polaroid

A circularly polarized light and polarizer technology, which is applied in the field of preparation of reflective circularly polarized light polarizers, can solve the problems of unstable optical properties, high brittleness of glassy liquid crystal materials, etc., achieves suitable mechanical properties, overcomes high brittleness, The effect of simple film forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of Mesogen Density Gradient Distribution Composite Films

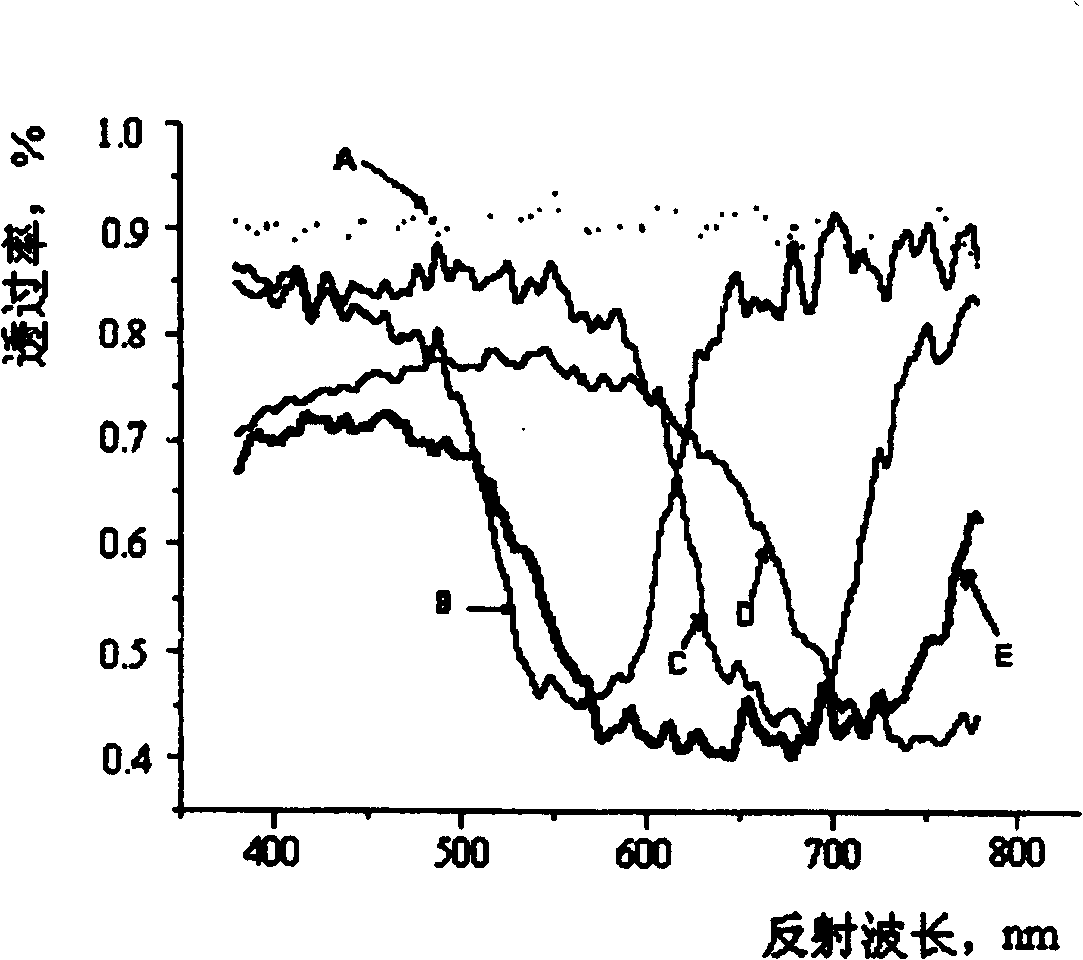

[0025] The glassy cyclosiloxane liquid crystals with central reflection wavelengths of 550nm, 660nm and 750nm (the central reflection wavelengths refer to those obtained under the same process conditions in different glassy liquid crystals) were mixed with dichloromethane, photoinitiator, The photopolymerizable monomers, solvents, etc. are mixed evenly. First, coat the glass substrate with a mixed solution with a central reflection wavelength of 550 nm. Under dark conditions, evaporate the solvent at room temperature; 24 hours later, coat the central reflection on the basis of this film. The mixed solution with a wavelength of 660nm, under the dark condition, volatilizes the solvent at room temperature; 24 hours later, the mixed solution with the central reflection wavelength of 750nm is coated on the basis of the film, and under the dark condition, the solvent is volatilized at room temperature to ob...

Embodiment 2

[0031] Preparation of Mesogen Density Gradient Distribution Composite Films

[0032] The glassy cyclosiloxane polymer liquid crystal with the central reflection wavelengths of 550nm, 660nm and 750nm is mixed with photoinitiator, polymerization inhibitor, dichloromethane, etc., respectively, and after vacuum drying, powder is made separately; The powders were mixed uniformly in a ratio of 1:1:1.

[0033] Orientation processing

[0034]The mixed powders with different central reflection wavelengths are placed on the surface of the glass substrate that has been polished and oriented with alcohol cotton, and then the glass substrate with the mixed powders and the polyester film substrate that has been polished and oriented on the surface are placed in a 90°C heat. On the stage, after half a minute, the polyester film is covered on the surface of the composite film, and the roller is oriented.

[0035] Fixation of molecular helical structure and pitch gradient distribution

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com