Actuator power-supply for driving laser diode

A laser diode, switching power supply technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as current overshoot, power grid fluctuation, circuit self-locking, etc., to achieve stable current output, high power factor, and suppression circuits Effects of the transition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of this invention will be further described below in conjunction with the accompanying drawings.

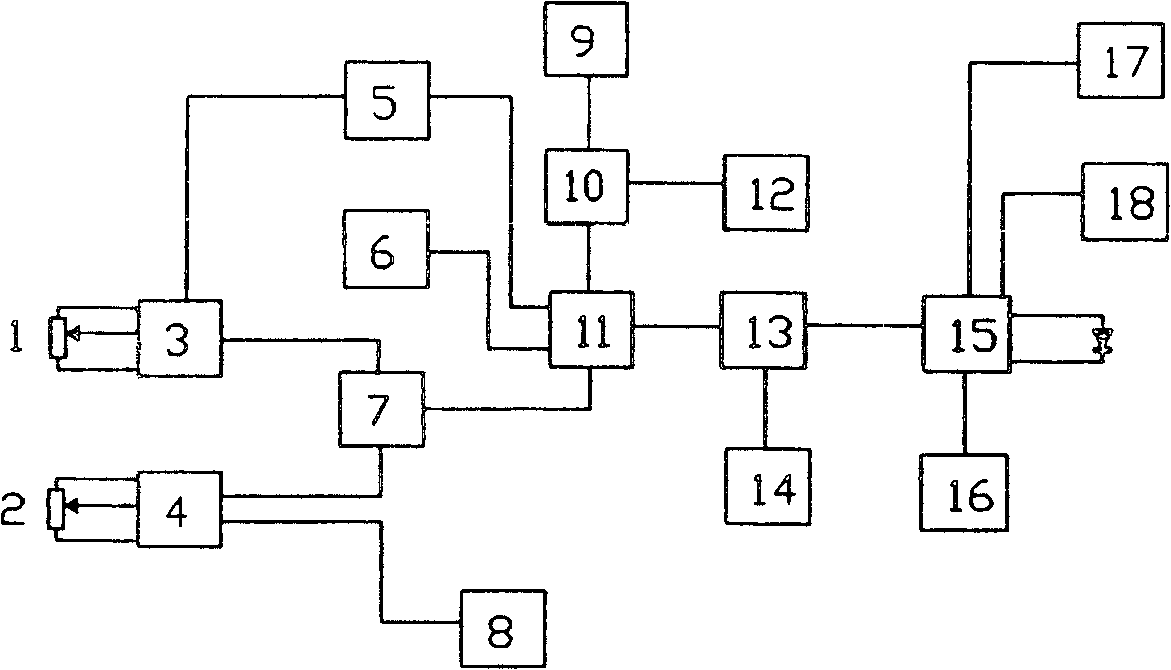

[0028] Please refer to figure 1 As shown, a switching power supply for driving laser diodes, which includes a multi-turn potentiometer 1 and an operating current amplifier 3 connected to adjust the working current, and a multi-turn potentiometer 2 connected to set the maximum current and set the current amplifier 4. The working current amplifier 3 and the setting current amplifier 4 are connected to the current value comparison gate 7, the output of the current value comparison gate 7 is connected to the output current controller 11, and the output current controller 11 is connected to the internal control and external control conversion device 13, and connect the laser through a large current power module 15.

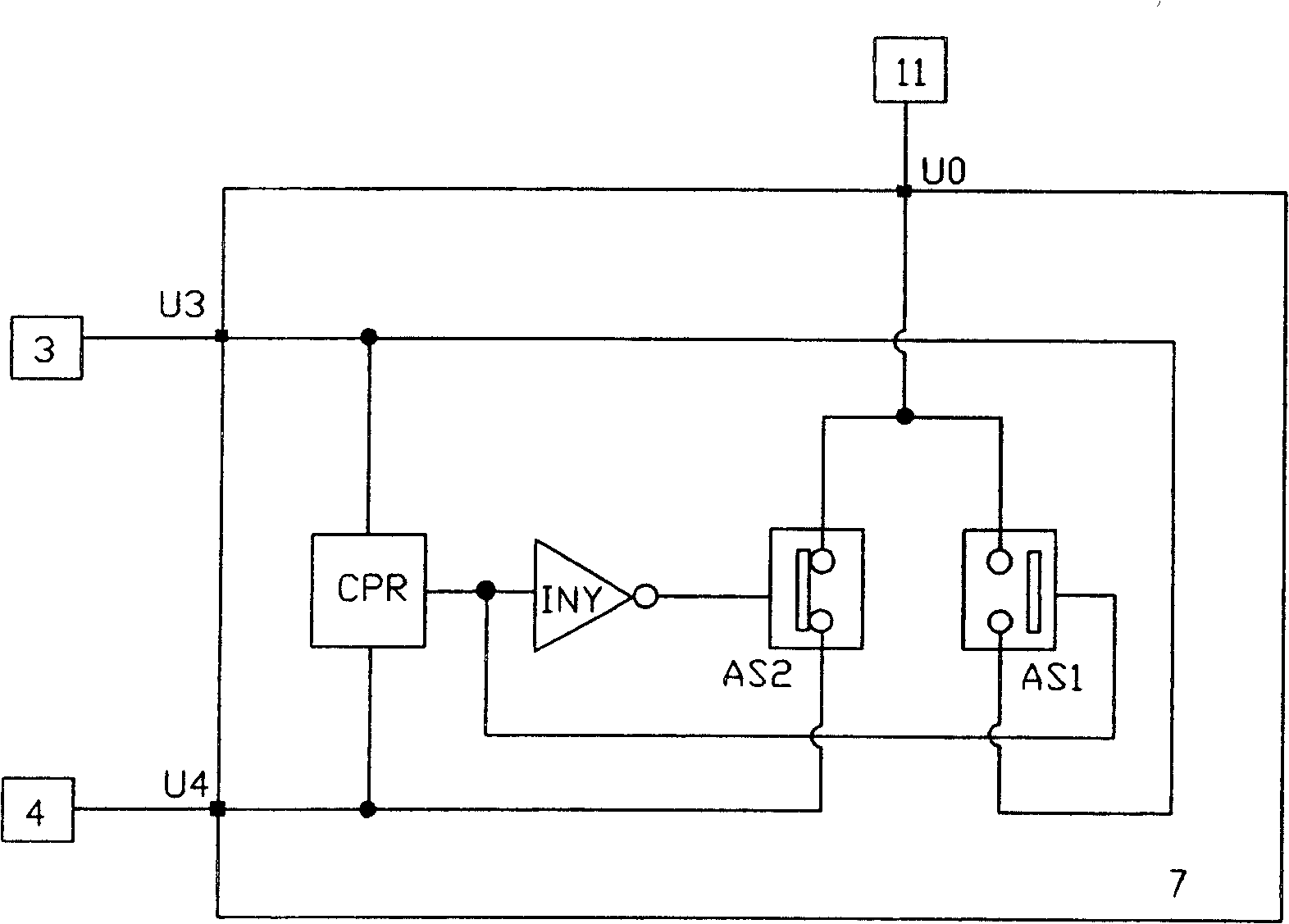

[0029] Wherein the structure of the current value comparison gate 7 is as follows figure 2 As shown, where CPR is a comparato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com