Organic light emitting diode and its producing method

A light-emitting diode, organic technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of complex process, low yield, and many defects, and achieve simple process, extended life, and good white balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

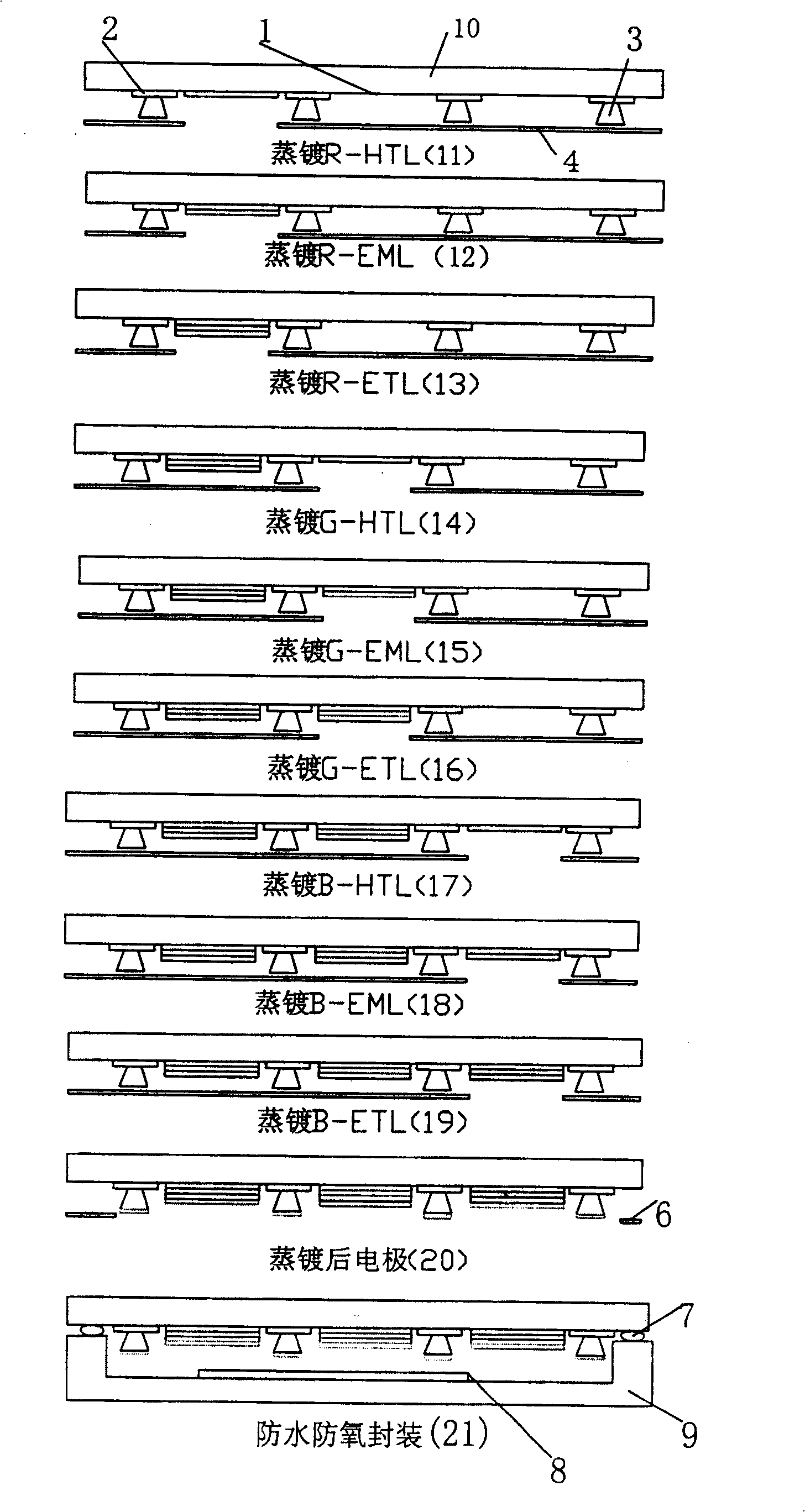

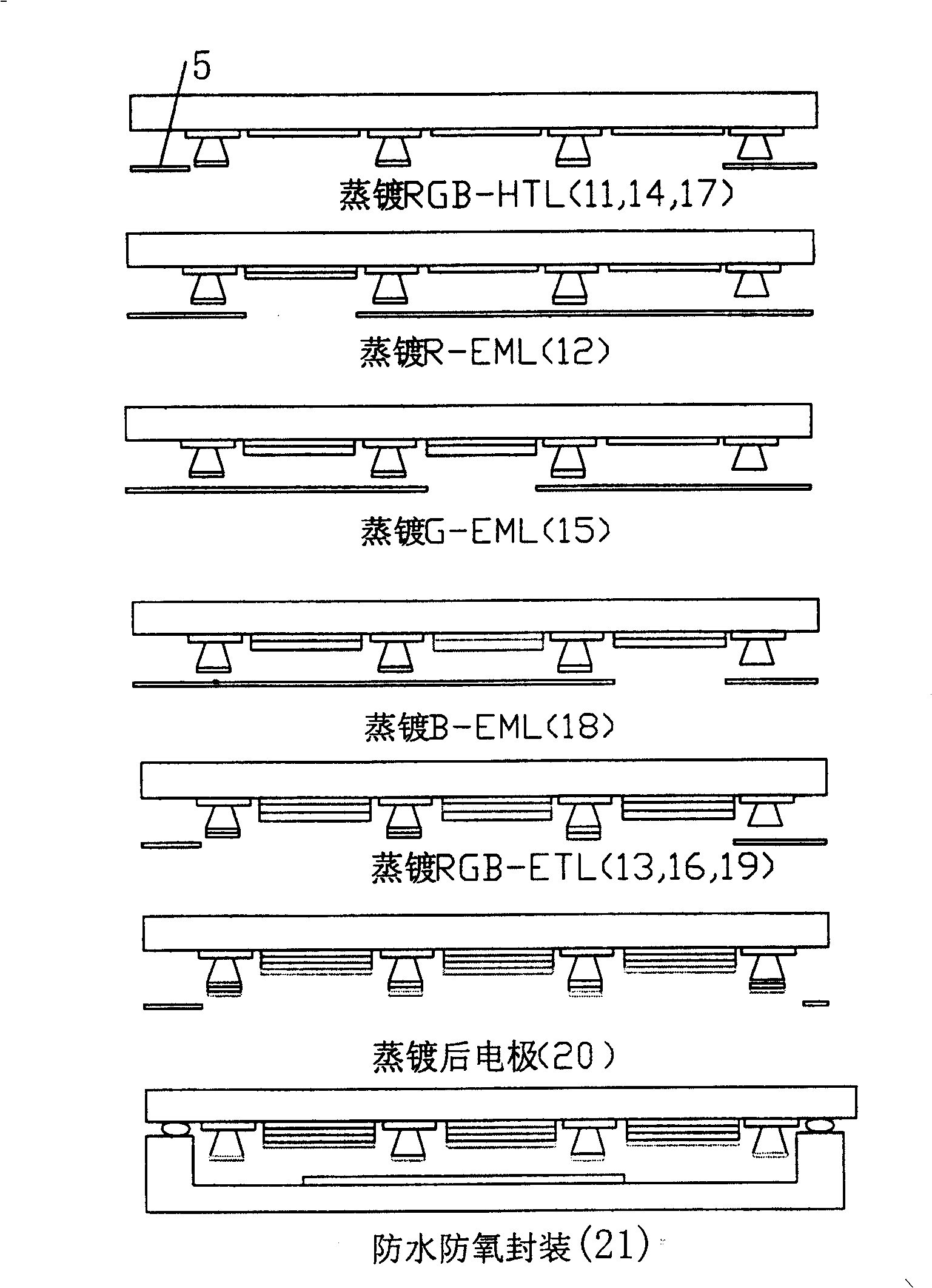

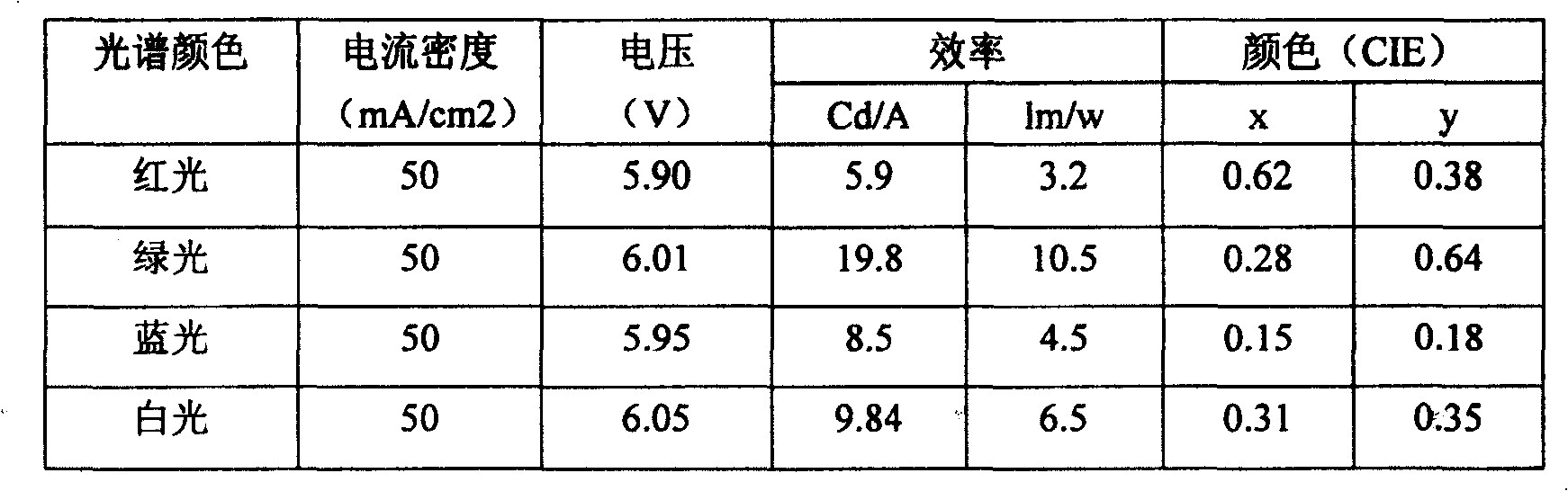

[0020] The full-color organic light-emitting diode of the present invention is mainly composed of two electrodes, the cathode and the anode, and an organic functional layer located between the two electrodes, wherein the organic functional layer includes a hole-transporting functional layer, three light-emitting functional layers of red, green and blue, and an electron-transporting functional layer. , the above-mentioned three independent light-emitting functional layers of red, green and blue all use the same host material, the main peak of the visible light spectrum of the electroluminescence of the host material is less than 480nm, and the energy gap is between 2.8ev~4ev, and each light-emitting functional layer is correspondingly doped to emit 400~ Luminescent materials with different objects within the wavelength range of 700nm; the weight ratio of the object material to the host material in each light-emitting functional layer is between 0.1% and 10%, and the object can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com