Power machine using inflammable powder as material

A technology for power machines and raw materials, applied in gas turbine devices, machines/engines, combustion chambers, etc., can solve the problems of high manufacturing cost, long installation period, waste of resources and environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

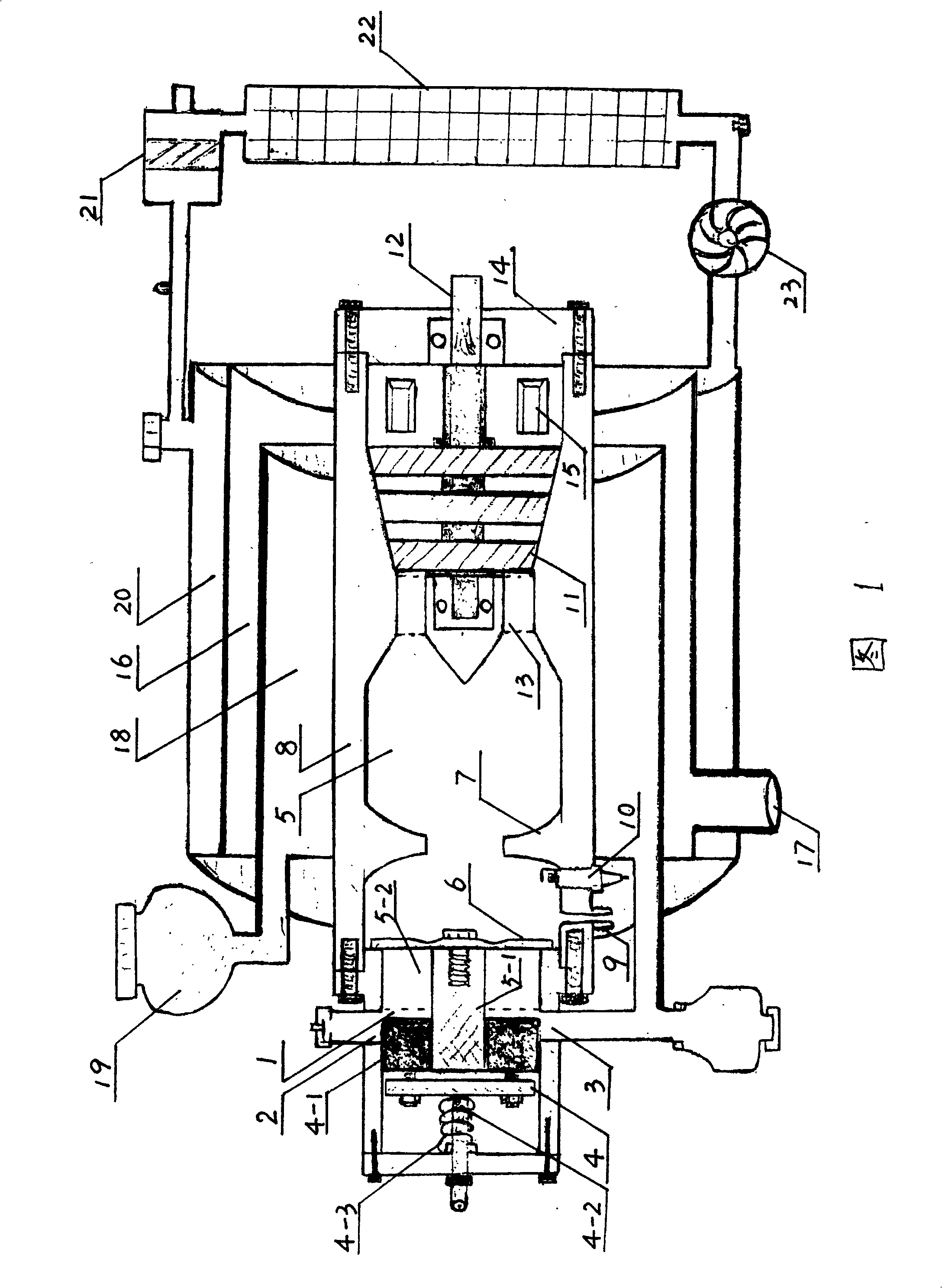

Embodiment 1

[0012] Embodiment 1: As shown in Figure 1, the air inlet chamber (1) is a cylindrical structure, and its wall is made of steel, and the two side walls of the air inlet chamber are respectively provided with an air inlet (2), a feed hole (3), the air intake hole can be covered with a cover with ventilation holes, so that the air intake chamber can communicate with the surrounding atmosphere, and the air intake chamber can enter the air through the air intake hole; combustible powder can enter through the feed hole; in the air intake chamber There is a control plug (4) at the front end, which is used to control the amount of intake air and feed material. The structure of the control plug is: the outer circumference of the piston (4-1) is closely attached to the cylindrical inner wall of the air intake chamber, The piston can be made of high-temperature-resistant material, and can move back and forth in the air intake chamber (the front and rear direction described in this embodim...

Embodiment 2

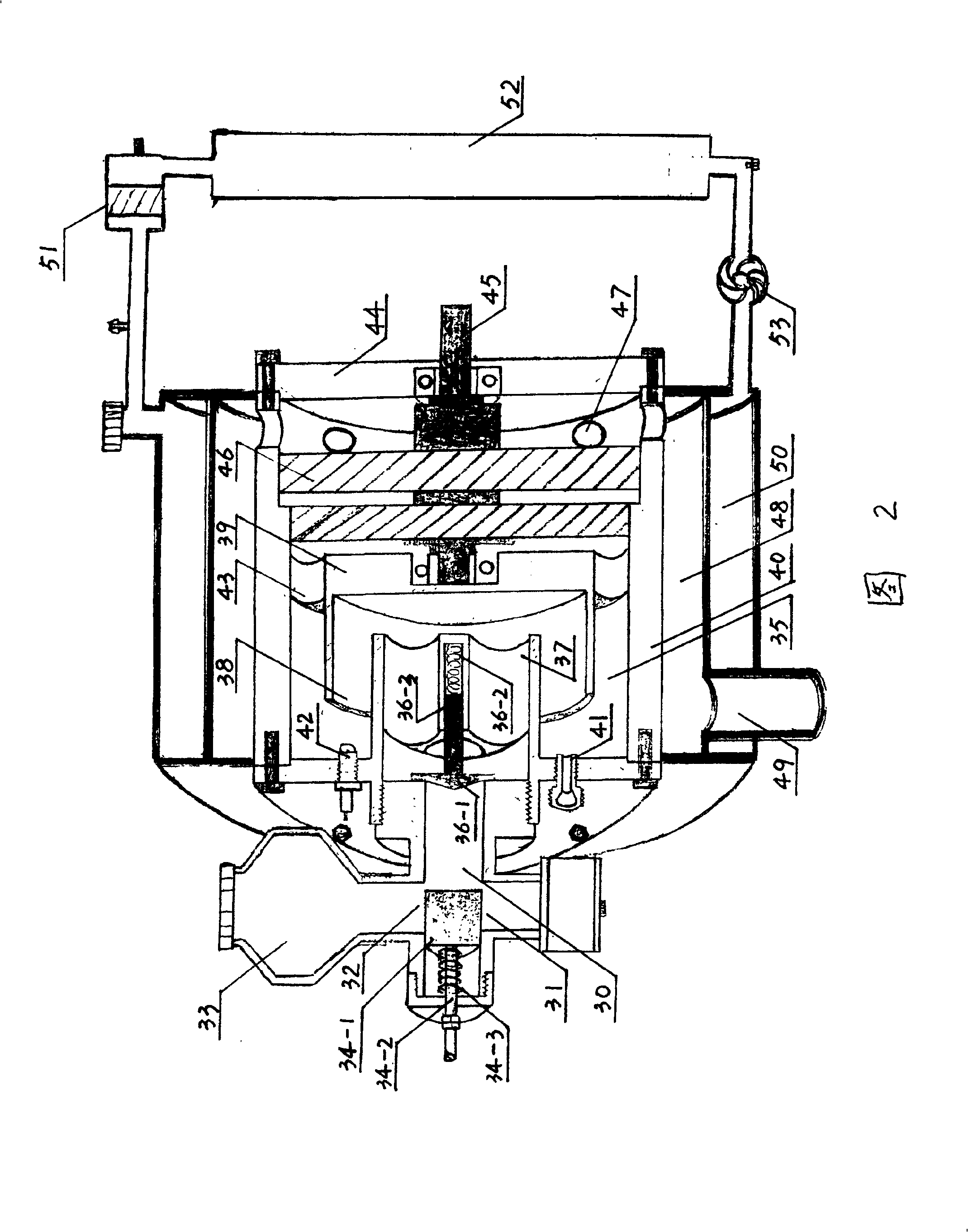

[0022] Embodiment 2: as shown in Figure 2, the air inlet chamber (30) is a cylindrical structure, and the two side walls of the air inlet chamber are respectively provided with an air inlet (31), a feed hole (32), and the air inlet The hole can be covered with a cover with an air filter, so that the air inlet chamber communicates with the surrounding atmosphere, and the air inlet chamber can enter the air through the air inlet hole; The material hole can enter combustible powder, and a control plug (34) is provided at the front end of the air intake chamber. The structure of the control plug is: the outer circumference of the piston (34-1) is close to the cylindrical inner wall of the air intake chamber, And can move back and forth in the air intake chamber (the front and rear direction described in this embodiment, with the fuel moving from front to back as the criterion), the piston is connected to the connecting rod (34-2), and the connecting rod is covered with a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com