Antistatic flame-proof light high-intensity resin steel mesh composite tube and production technique

A production process and high-strength technology, applied in non-polymer adhesive additives, pipes, rigid pipes, etc., can solve the problems of low bending resistance, difficult construction, poor impact load resistance, etc., and achieve enhanced bending resistance. Strength and resistance to shock loads, improved levels of friction and leakage resistance, improved wear resistance and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

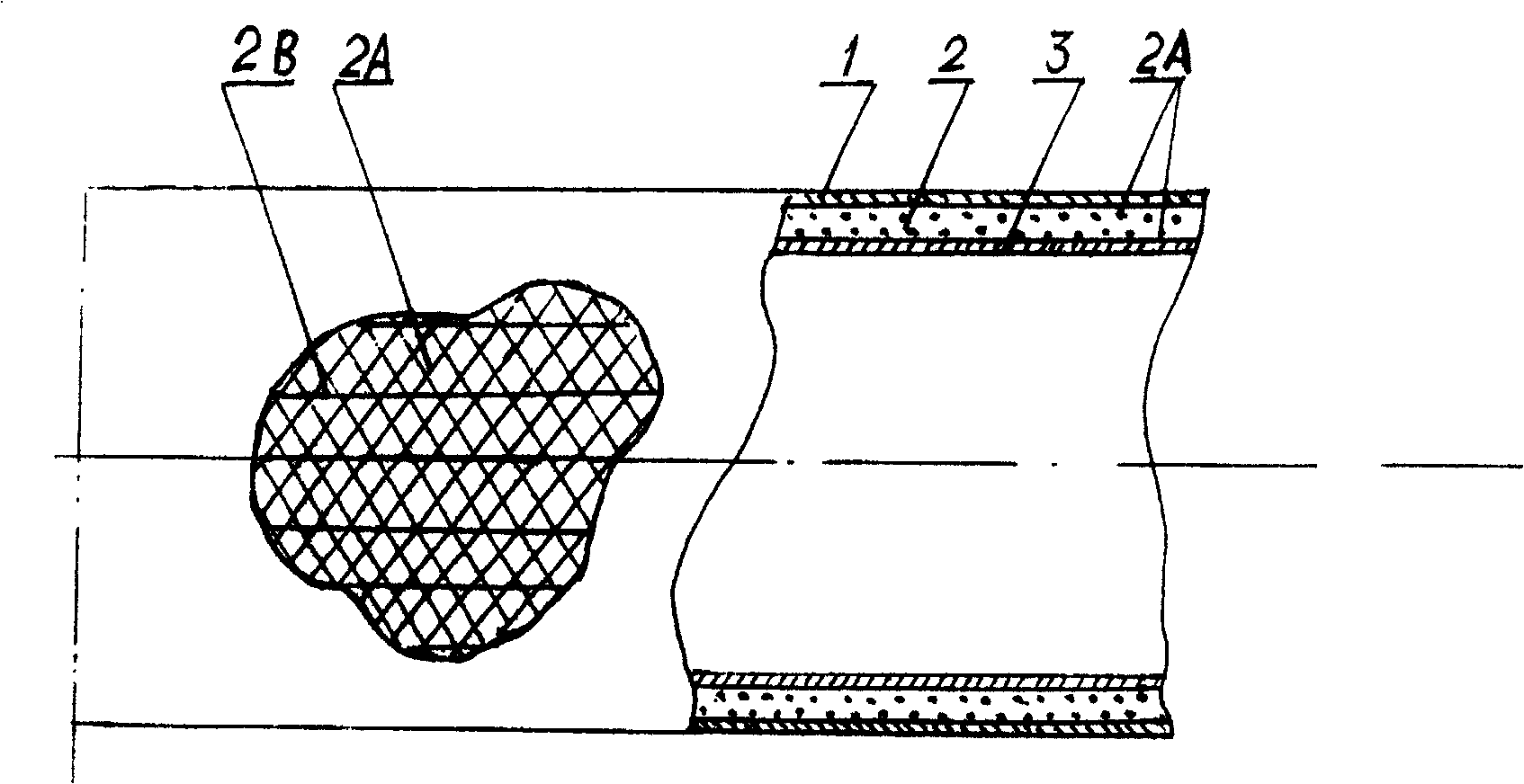

[0013] The stencil resin composite layer in the present invention is the focus of the improvement of the present invention, and the improvement also includes the improvement of the composite adhesive curing agent formula used for the processing of each layer. The specific process structure composition includes fiber, or fiber fabric, or one of fiber and fiber fabric with steel wire as the base material, and is composed of thermosetting resin glue with flame retardant, antistatic agent, curing agent, accelerator and filler. Composite adhesive curing agent, apply composite adhesive curing agent while winding the base material on the tubular mold, and form a pipeline combined with prefabricated flange fittings after final curing. The structure of the pipeline includes three layers: on the tubular mold 5 The inner lining layer 1 with anti-seepage or wear resistance formed by winding fibers and fabrics and uniformly coating the thermosetting resin adhesive with conductive and flame-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com