Hongcomb plate hollow glass

A honeycomb panel and glass technology, applied in glass/slag layered products, building components, heat preservation, etc., can solve the problems that the appearance effect and performance cannot meet the sunshade performance, weather resistance performance, new hollow glass, etc., to achieve good virtual light and shadow, avoid Condensation, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

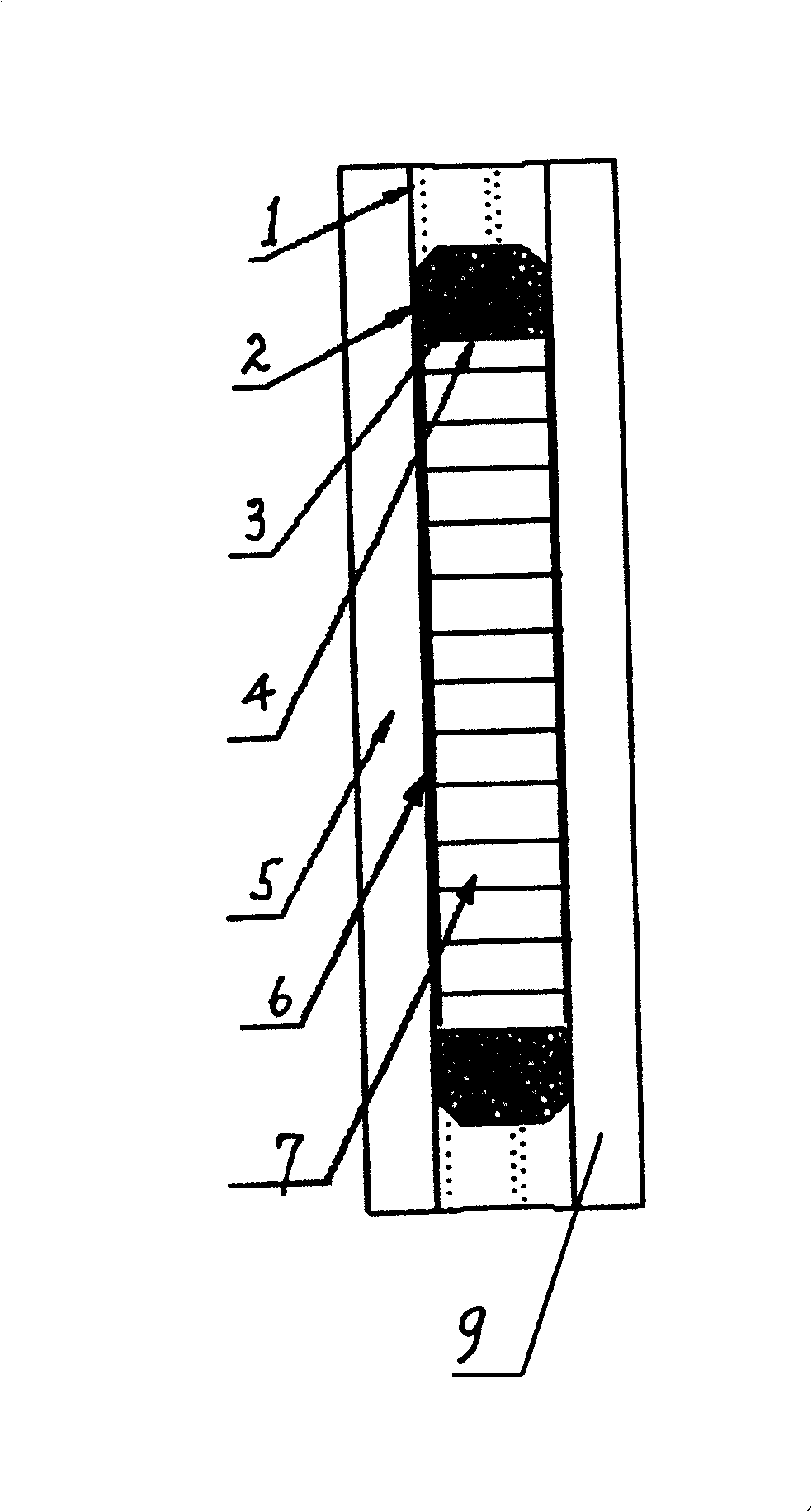

[0026] Please refer to the attached figure 1 As shown, the hollow glass structure is: a spacer frame 4 is sandwiched between the outer layer glass plate 9 and the inner layer glass plate 5; inside the spacer frame 4, a honeycomb panel 7 is installed. The spacer frame 4 is sealed with butyl glue 2 and secondary sealant 1 . The spacer frame 4 has a width of 6mm-24mm. The height of the honeycomb profile is 6-24mm. The thickness of the glass plates 5, 9 is 2mm-25mm.

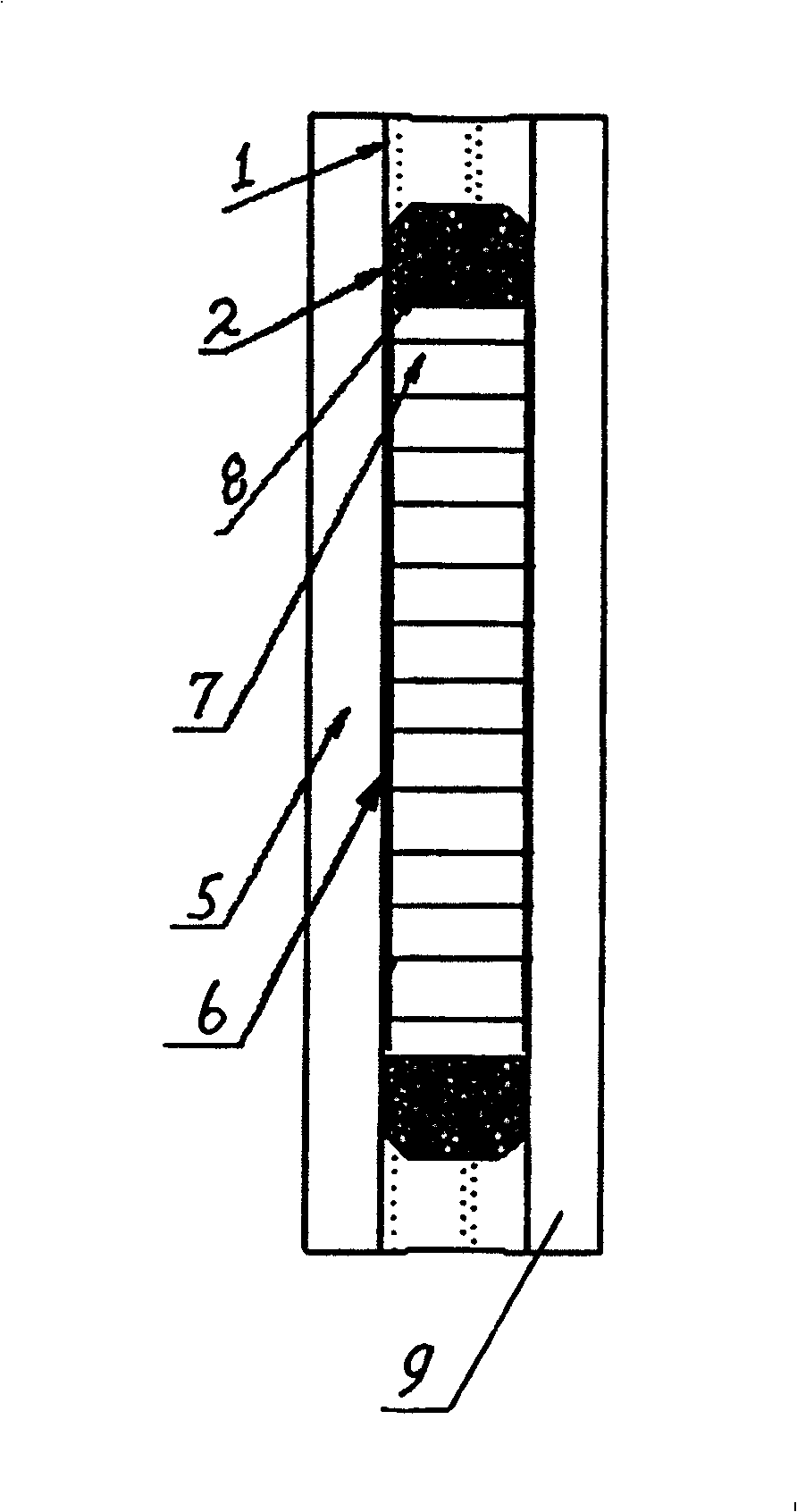

[0027] Please refer to the attached figure 2 As shown, the hollow glass structure is: a warm edge sealing strip 8 (Warm Edge Spacer) is sandwiched between the outer glass plate 9 and the inner glass plate 5; The sealing strip is sealed with butyl rubber and secondary sealant, with a width of 6mm-24mm. The thickness of the honeycomb panel 7 is 6-24mm. The thickness of the glass plates 5, 9 is 2mm-25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com