CMOSImage sensor and manufacturing method therefor

A technology of image sensor and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, radiation control devices, electrical components, etc., can solve the problems of high dark current and low photosensitivity, and achieve low dark current, high photosensitivity, and good photosensitivity The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

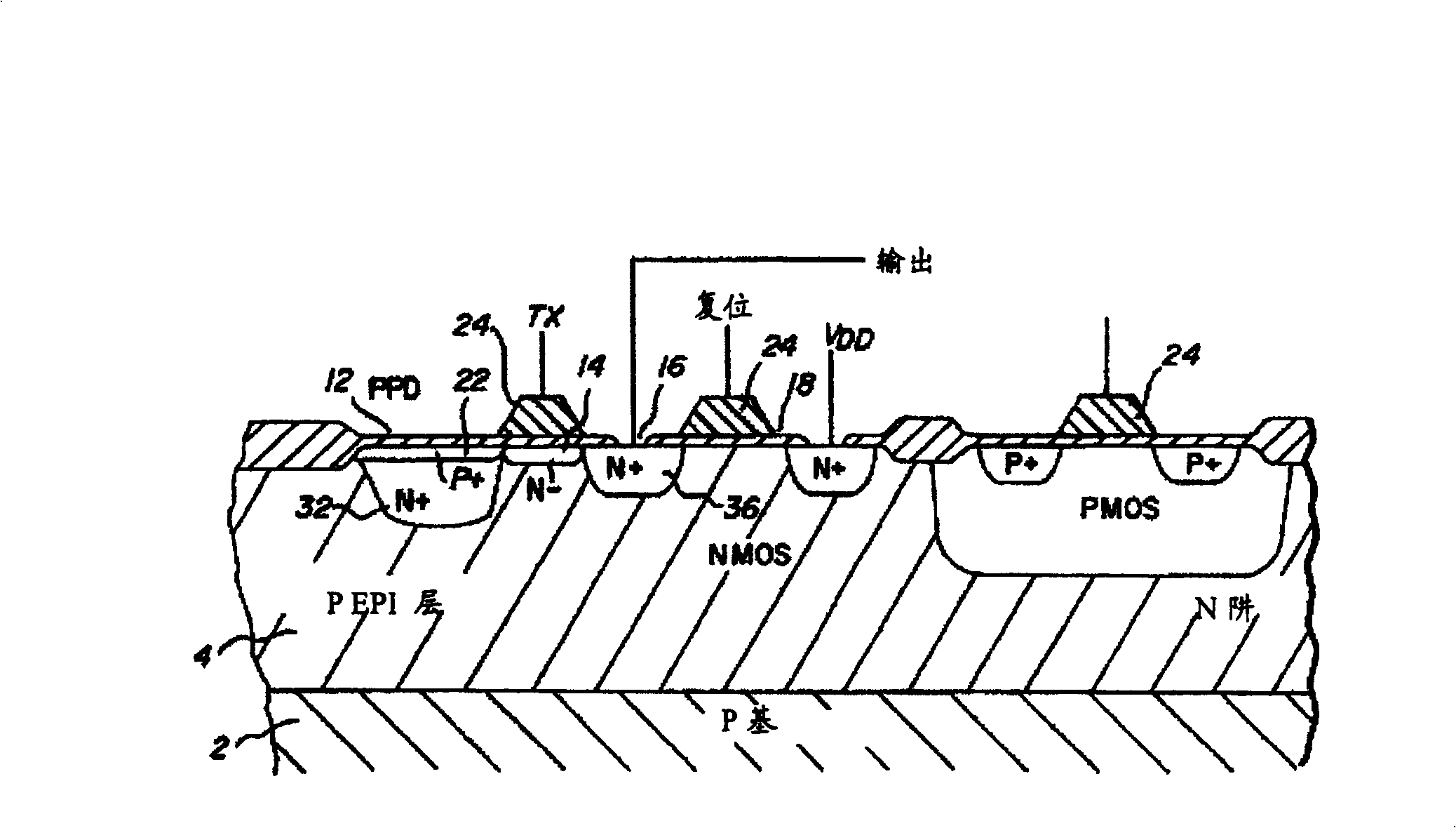

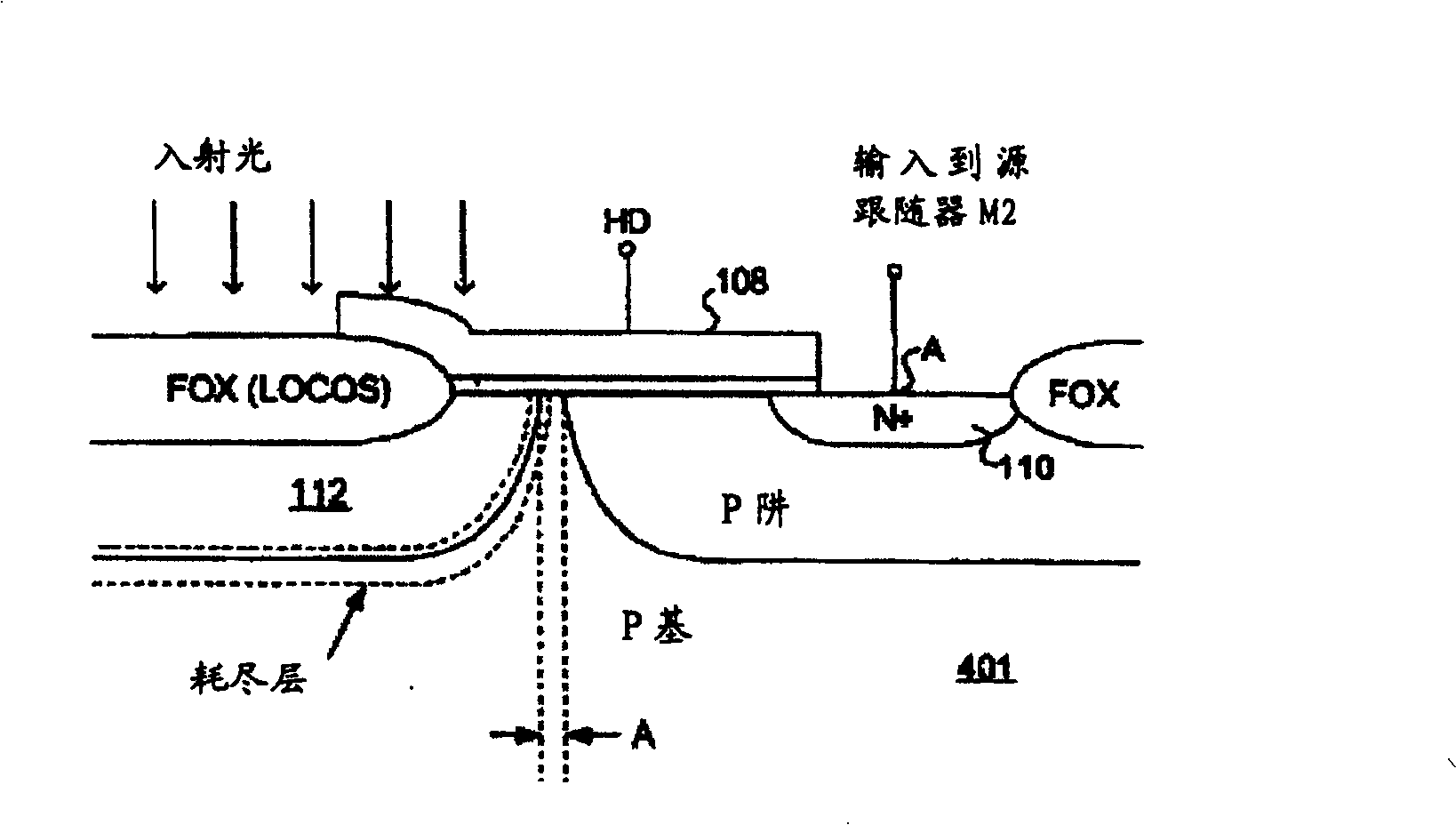

[0047] The CMOS image sensor of the present invention includes a photodiode area and a logic area. The logic area includes a source follower and a row gate. The photodiode region adopts a non-standard manufacturing method, and includes a field oxide region and an active region, on which a reset transistor and a photodiode are formed. The photodiode has a first pole and a second pole, wherein the first pole has a buried region surrounding the bottom and sidewalls of the field oxide region, and a needle-shaped region extending to the upper end of the buried region toward the reset transistor. The buried region isolates the junction of the photodiode from the bottom and edges of the field oxide region, thereby eliminating dark current that may exist at the bottom and edges of the field oxide region. The needle-shaped region is extremely sensitive to light because it is not covered by the field oxide region.

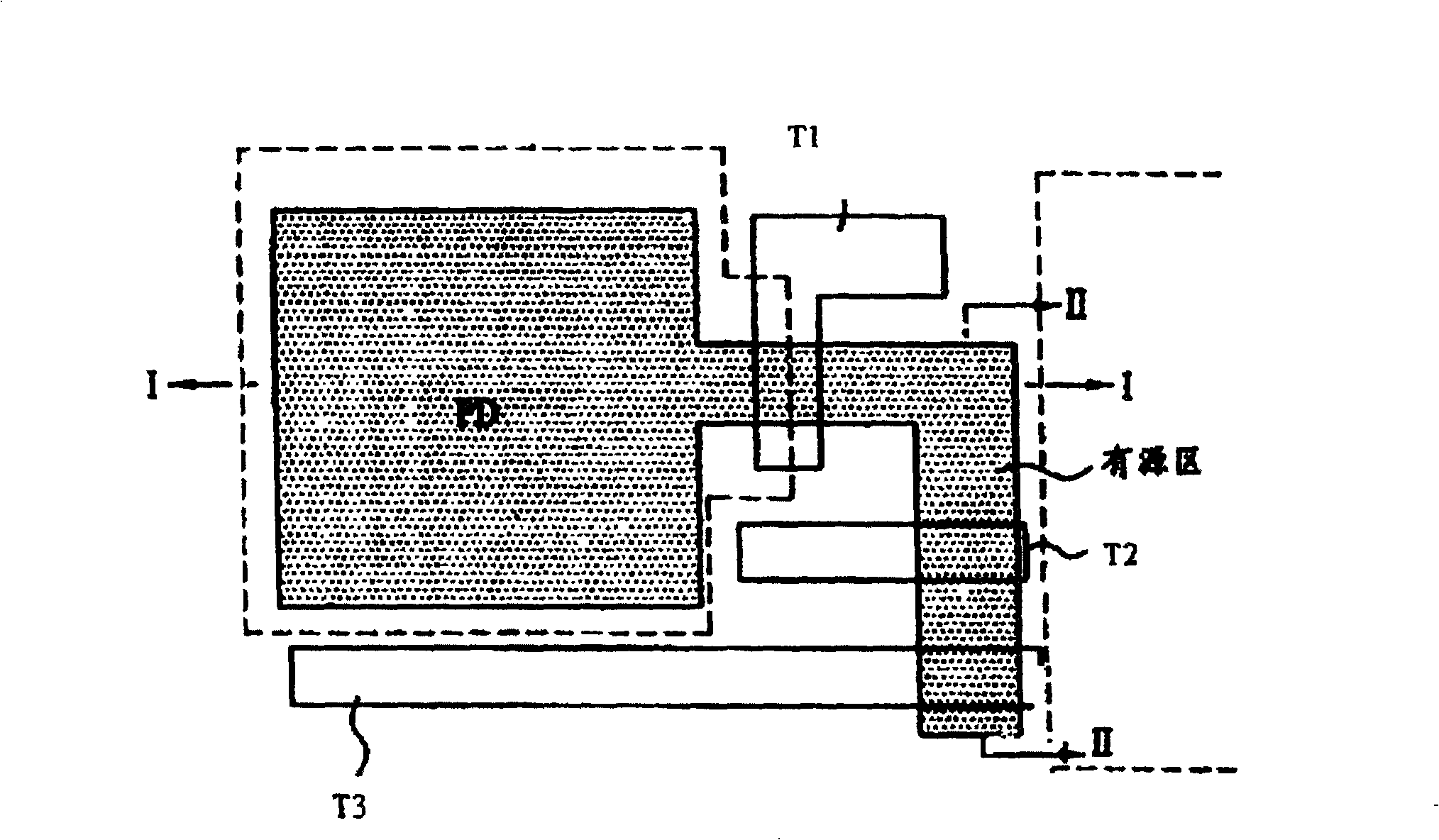

[0048] image 3 Shown is a layout diagram of unit pixels in the CMOS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com