A photodetector based on twisted bilayer graphene and its preparation method

A double-layer graphene, photodetector technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., to achieve the effects of high mobility, high photodetection efficiency, and low dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

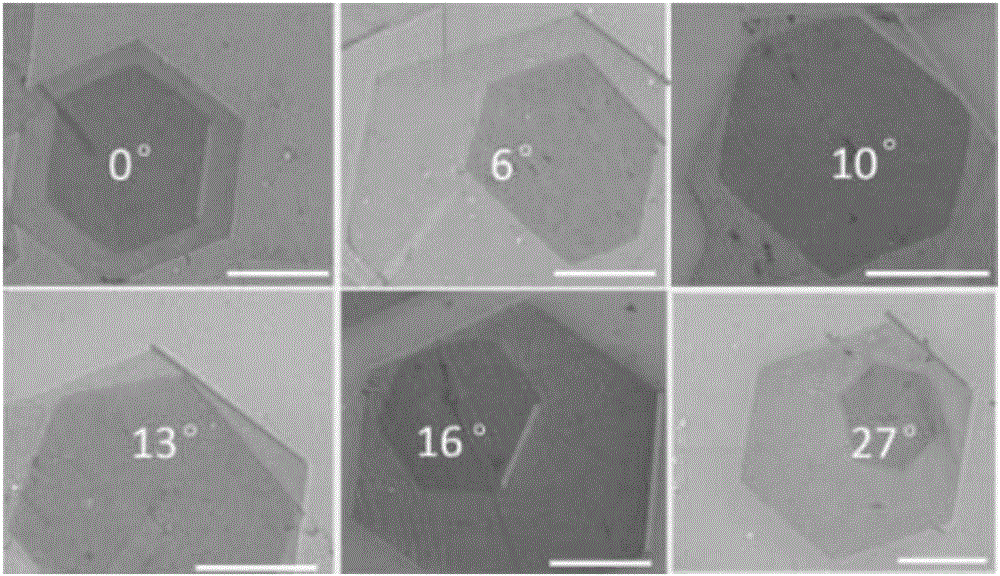

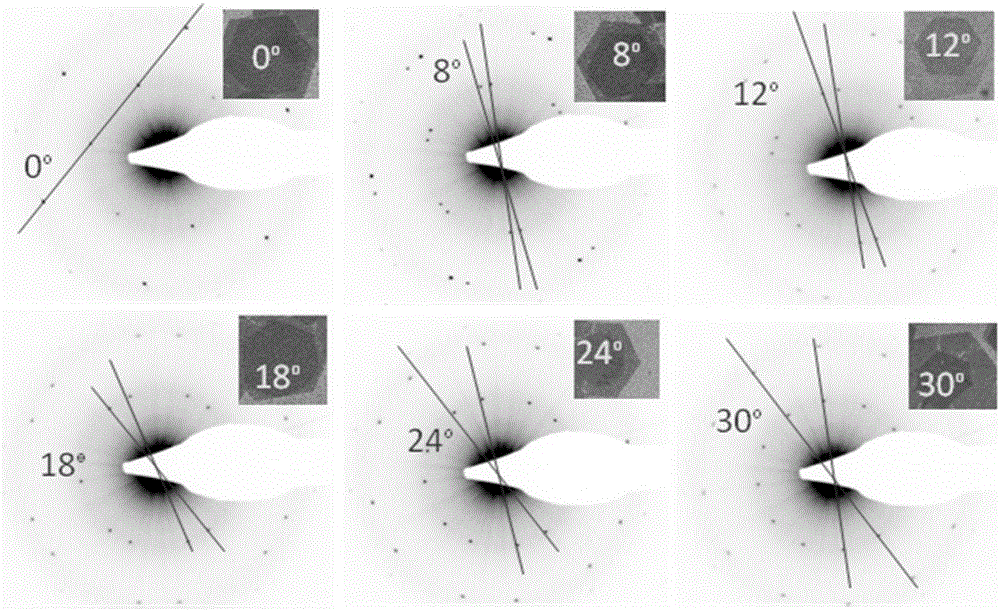

[0071] Example 1: Preparation of a twisted bilayer graphene-based photodetector enhanced by 532nm laser resonance

[0072] 1. Preparation of twisted bilayer graphene:

[0073] 1) Copper foil (copper foil with a purity of more than 99% and a thickness of 20-100 μm) is annealed at a high temperature of 1020-1040 °C in a hydrogen atmosphere. The annealing conditions are: the flow rate of hydrogen is 400-800 sccm, and the pressure is 1000-2000 Pa. Each annealing time is 20-60min to reduce the residual oxide on the surface of the copper foil to expand the size of the copper domain.

[0074] 2) Quickly transfer the copper foil from a high temperature zone of 1020-1040°C to a zone of 25°C to quickly lower the temperature of the copper foil; temperature, so cycled 3 times.

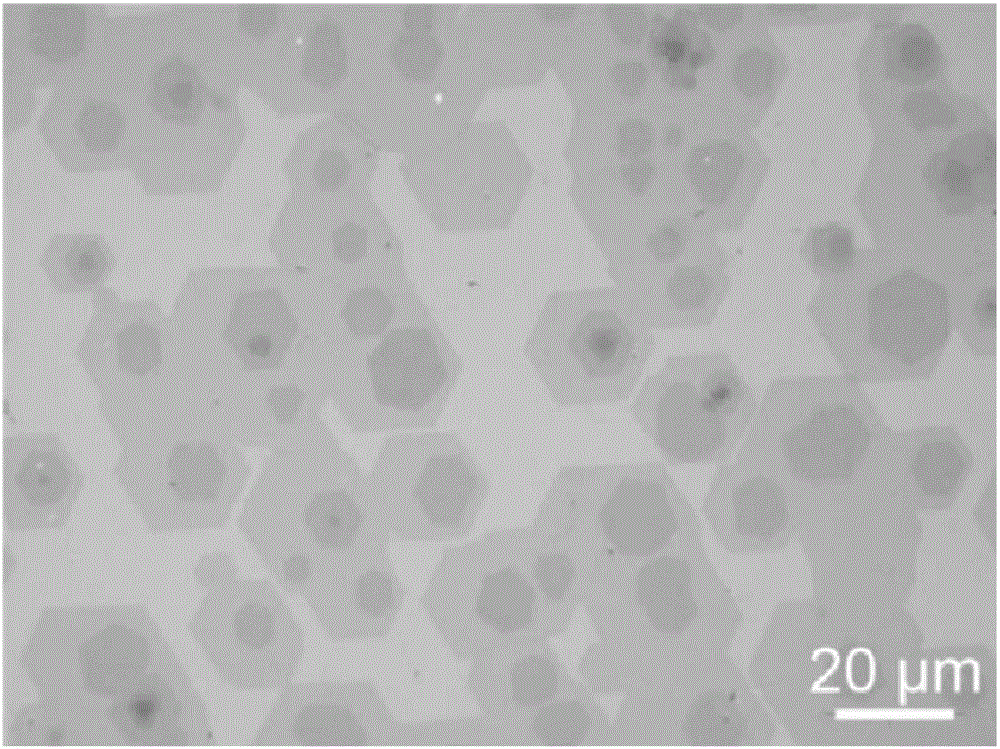

[0075] 3) At a high temperature of 1020-1040°C, feed methane gas (carbon source, purity not less than 99.999%) for 30 minutes, the flow rate of methane is 1 sccm, and the flow rate of hydrogen gas is 500 sccm, a...

Embodiment 2

[0093] Embodiment 2, preparation of a photodetector based on twisted bilayer graphene enhanced by 633nm laser resonance

[0094] 1. The preparation of twisted bilayer graphene is the same as that of (1) in Example 1.

[0095] 2. Fabrication of photodetectors based on twisted bilayer graphene:

[0096] 1) Select the twisted bilayer graphene prepared in (1) for screening, and select the sample with a twist angle of 13°. Coating polymethyl methacrylate (PMMA) on the sample with a coating thickness of 300nm, using electron beam exposure (the electron beam exposure process is 950K PMMA 3000r / min spin coating 50s, 170 ° C baking 3min) on the twisted double layer Make a 5-500 μm channel on the graphene, clean the channel with oxygen plasma, the power of the oxygen plasma is 90W, the oxygen flow rate is 15sccm, and the time is 3min, and then use 25% of the mass fraction of tetramethyldipentyl A ketone (isopropanol as a solvent) developer was developed for 2 min, and an isopropanol f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com