Manufacturing method of organic electroluminescense display device

A display device, electroluminescence technology, applied in electroluminescence light sources, electric light sources, lighting devices, etc., can solve problems such as unfavorable production cost, reduction, and redundant manufacturing process, and achieve high yield performance and reduce contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

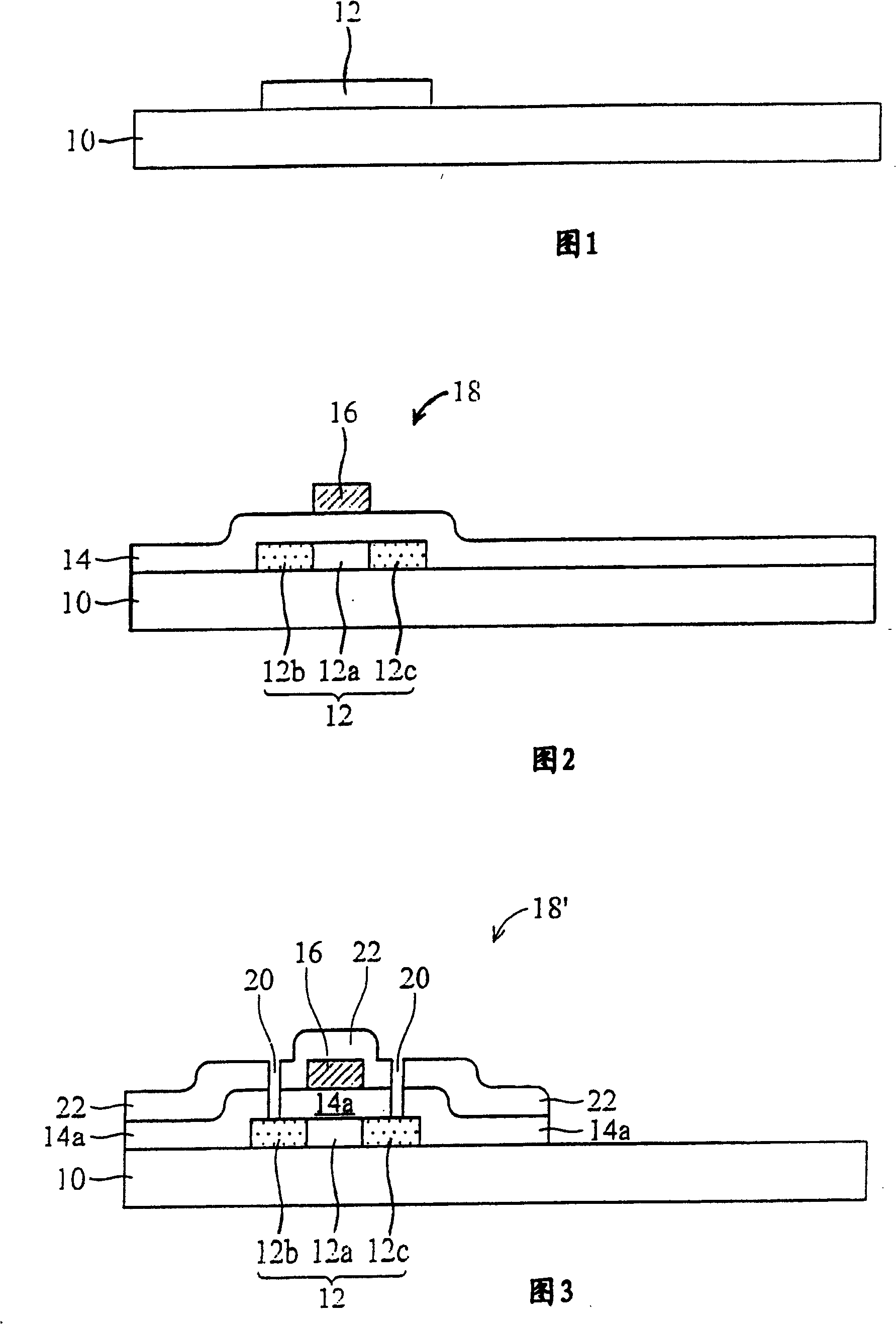

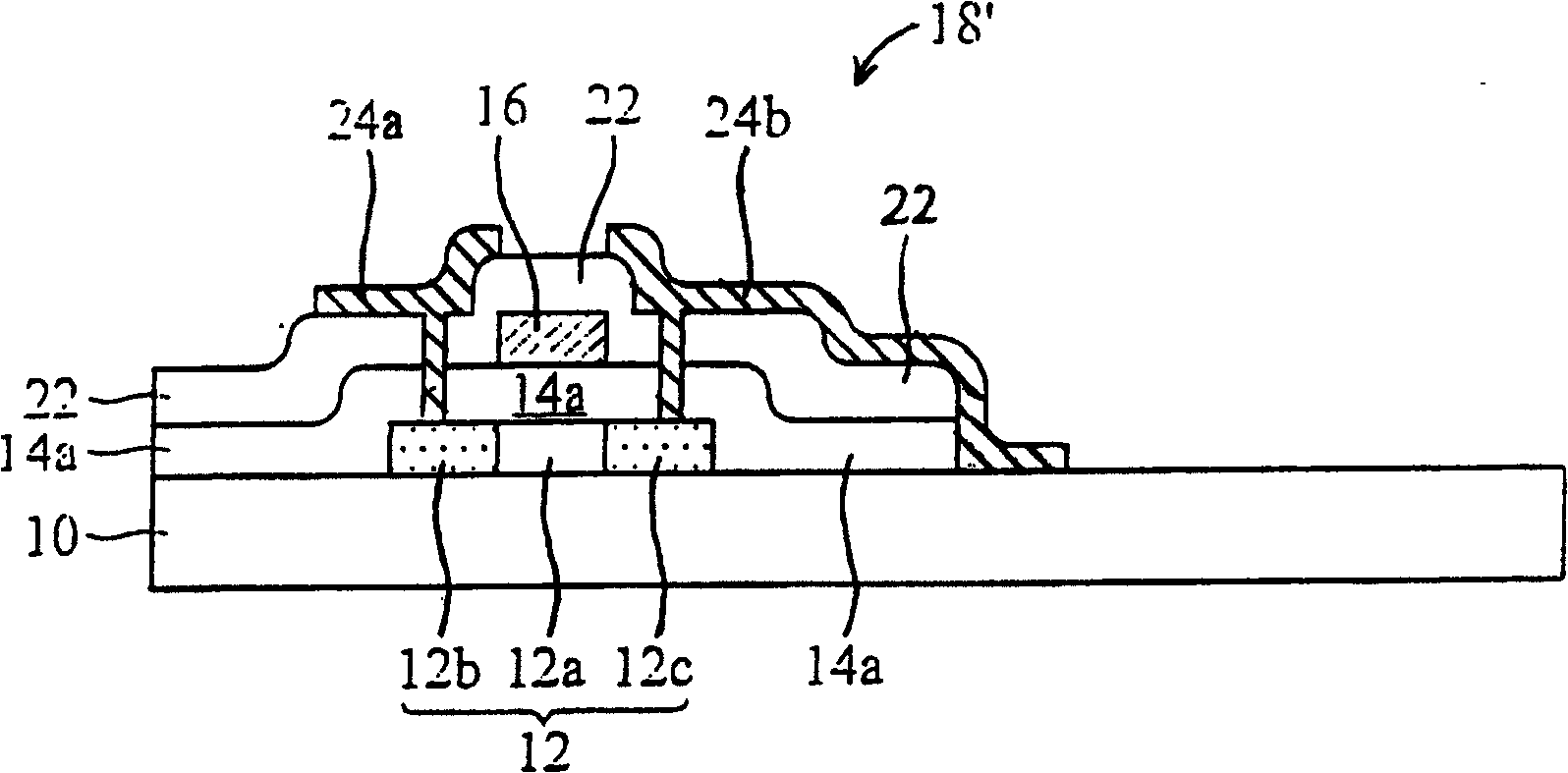

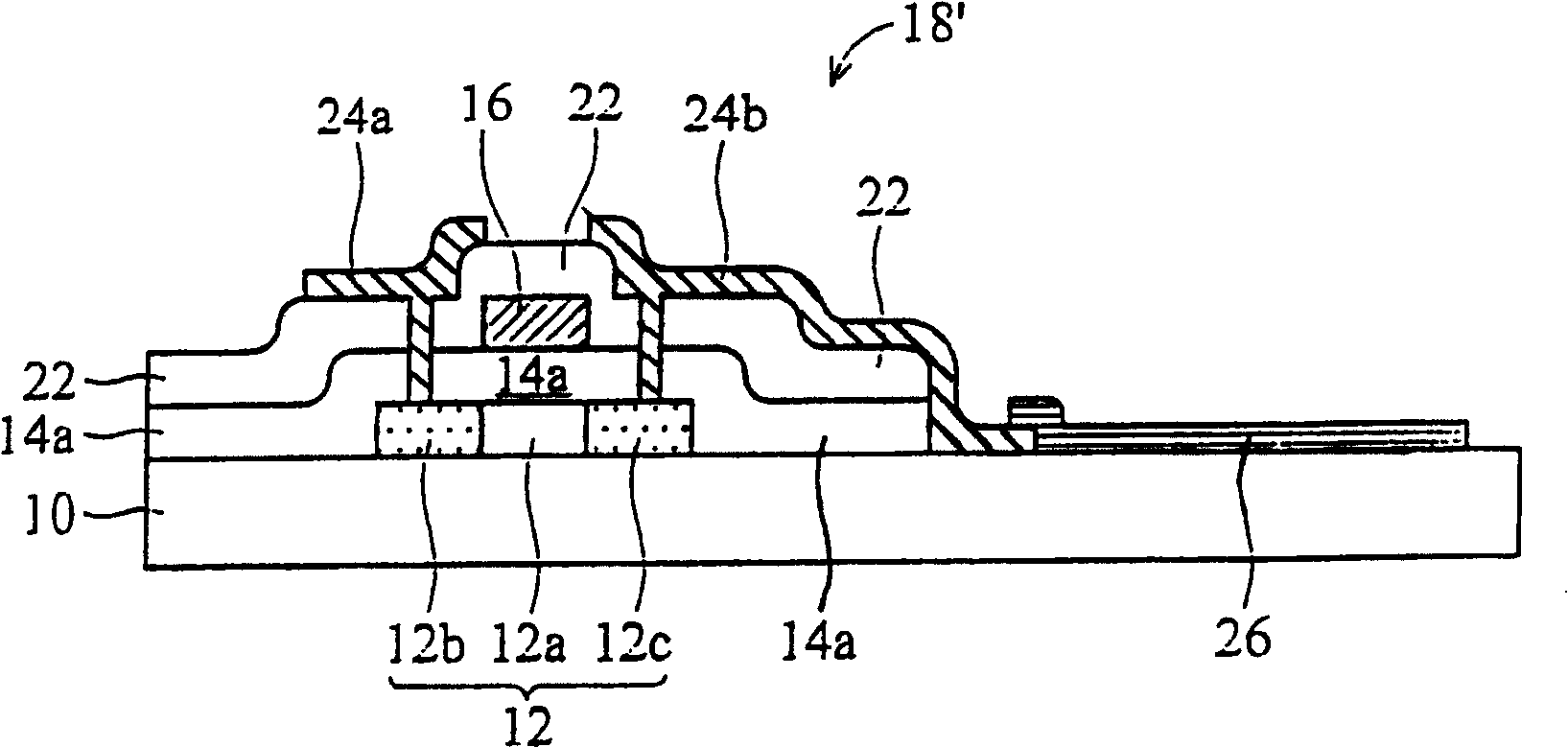

[0022] Embodiments of the present invention will cooperate with Figures 1 to Figure 7 The cross-sectional flow chart is described in detail as follows. As shown in Figure 1, first provide a transparent substrate 10, this transparent substrate 10 can be a transparent glass substrate or a transparent plastic substrate, if it is a plastic substrate, its material can be polyethylene terephthalate (polyethyleneterephthalate), polyester ester (polyester), polycarbonate (polycarbonates), polyacrylate (polyacrylates) or polystyrene (polystyrene). A buffer layer can also be formed on the transparent substrate, such as a composite buffer layer composed of a silicon nitride layer and a silicon oxide layer, so as to improve the adhesion between the subsequent film layer and the transparent substrate 10 and improve transparency. The roughness of the surface of the substrate 10. Next, an active layer is formed on the transparent substrate 10, such as a polysilicon layer or an amorphous si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com