Device and method for wafer alignment with reduced tilt sensitivity

A technology for aligning devices and diffracting light beams, which is applied in the directions of optomechanical equipment, microlithography exposure equipment, transportation and packaging, etc., can solve problems such as complex costs, and achieve the effect of reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

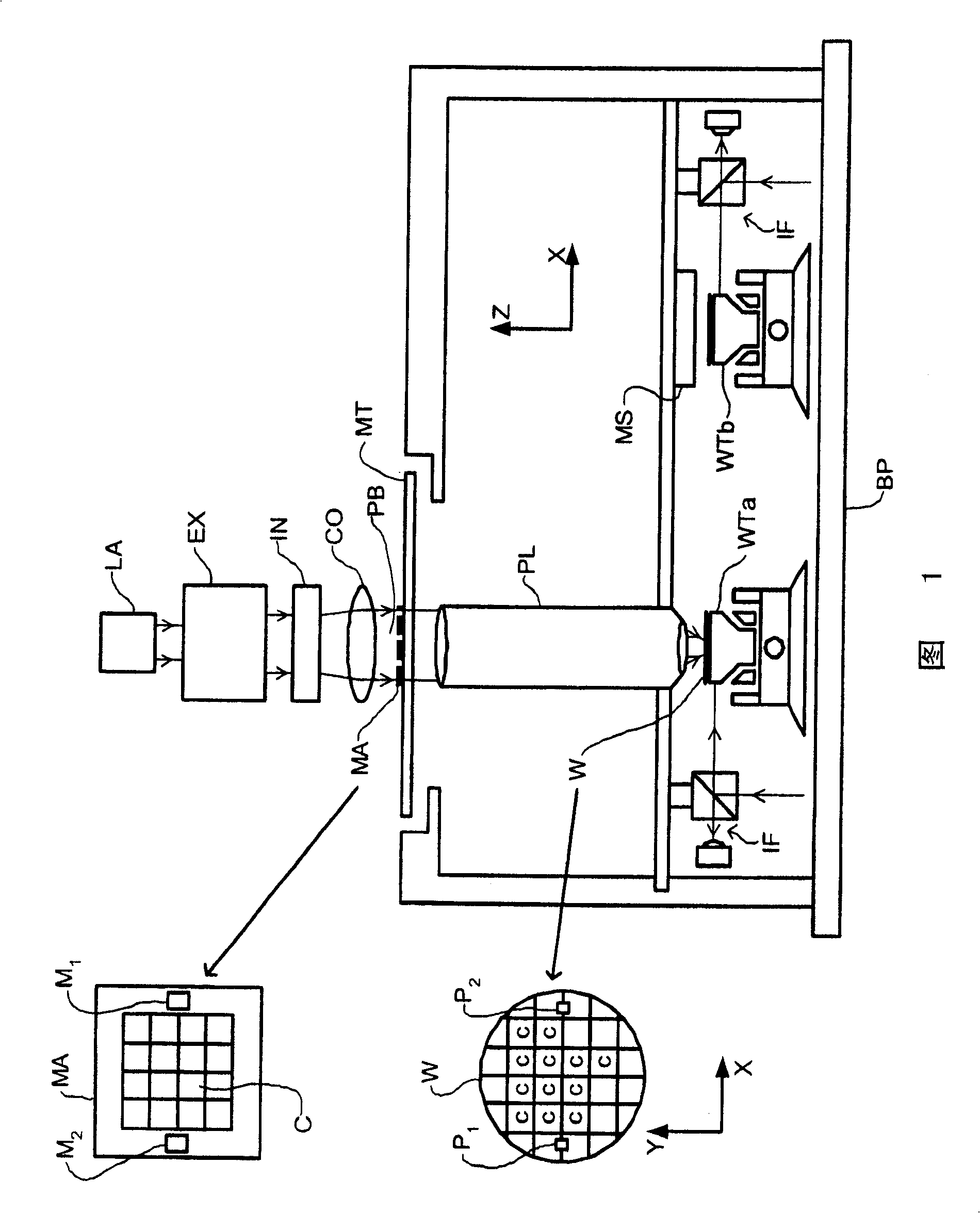

[0060] Figure 1 schematically depicts a lithographic projection apparatus 1 of a specific embodiment of the present invention. The device is of the type with two substrate tables WTa and WTb, comprising:

[0061] - A radiation system Ex, IL providing a radiation projection beam PB (eg UV radiation). In this particular example, the radiation system also includes a radiation source LA;

[0062] - a first stage (mask table) MT provided with a mask holder for holding a mask MA (eg reticle) and with a first positioning device for precise positioning of the mask relative to the object PL Device PM connection;

[0063] - second and third stages (substrate tables) WTa and WTb, each provided with a substrate holder for holding a substrate W (e.g. a resist-coated silicon wafer), and each connected to a respective stage position device (not shown), the second object stage is positioned under the projection system PL, and its stage positioning device is arranged to precisely position t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com