Shaft kiln heat recovery method and device

A heat energy recovery and shaft kiln technology, applied in the field of cement building materials, can solve the problems of affecting the crushing particle size and the service life of equipment, increasing the labor intensity of workers, and harming the health of workers, etc., and achieves the effect of simple structure, increased thickness and reduced coal consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

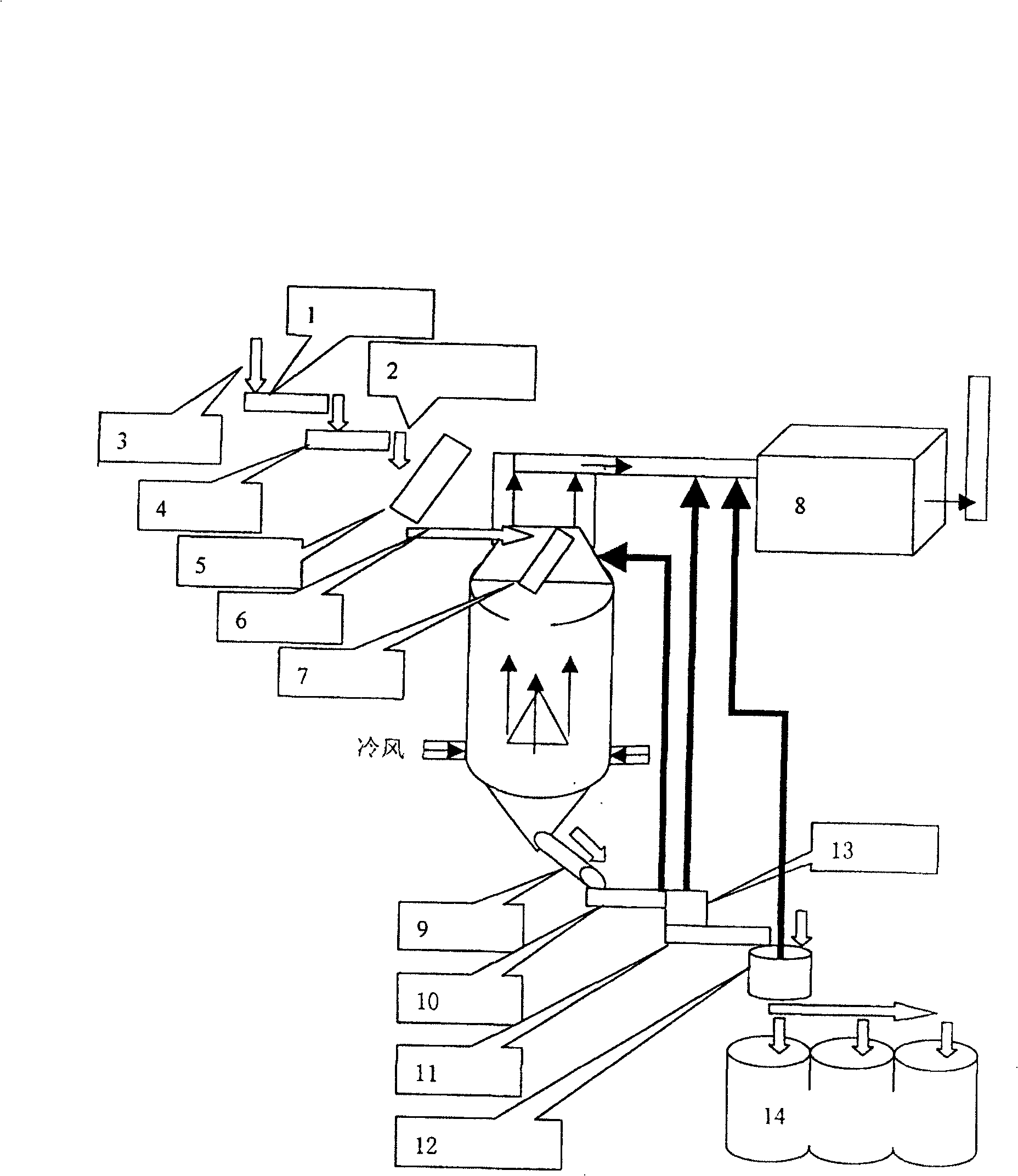

[0014] The exhaust gas from the grate cooler passes through the pipeline, enters the kiln surface and mixes the kiln surface flue gas, and then enters the dust collector; due to the high temperature of the flue gas, the bag is not easy to condense, which greatly prolongs the service life of the equipment and reduces the labor intensity of the workers. Since the flue gas entering the dust collector is mixed with the flue gas from the kiln and the exhaust gas from the grate cooler, the temperature of the flue gas from the kiln is allowed to be lower, so the preheating zone can be thickened, the thickness of the wet material layer can be increased, and the coal consumption can be reduced.

[0015] Due to the forced rapid cooling of the clinker in the grate cooler, the clinker breaks and disperses to produce a lot of fine ash and water vapor. After the clinker leaves the grate cooler and enters the dust collector,

[0016] It can enter the dust collector through the pipeline, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com