Treatment process for industrial wastewater of yellow phosphorus production

A technology of industrial wastewater and treatment methods, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of surrounding residents' life and work impact, achieve the effects of increased recovery rate, reduced investment, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

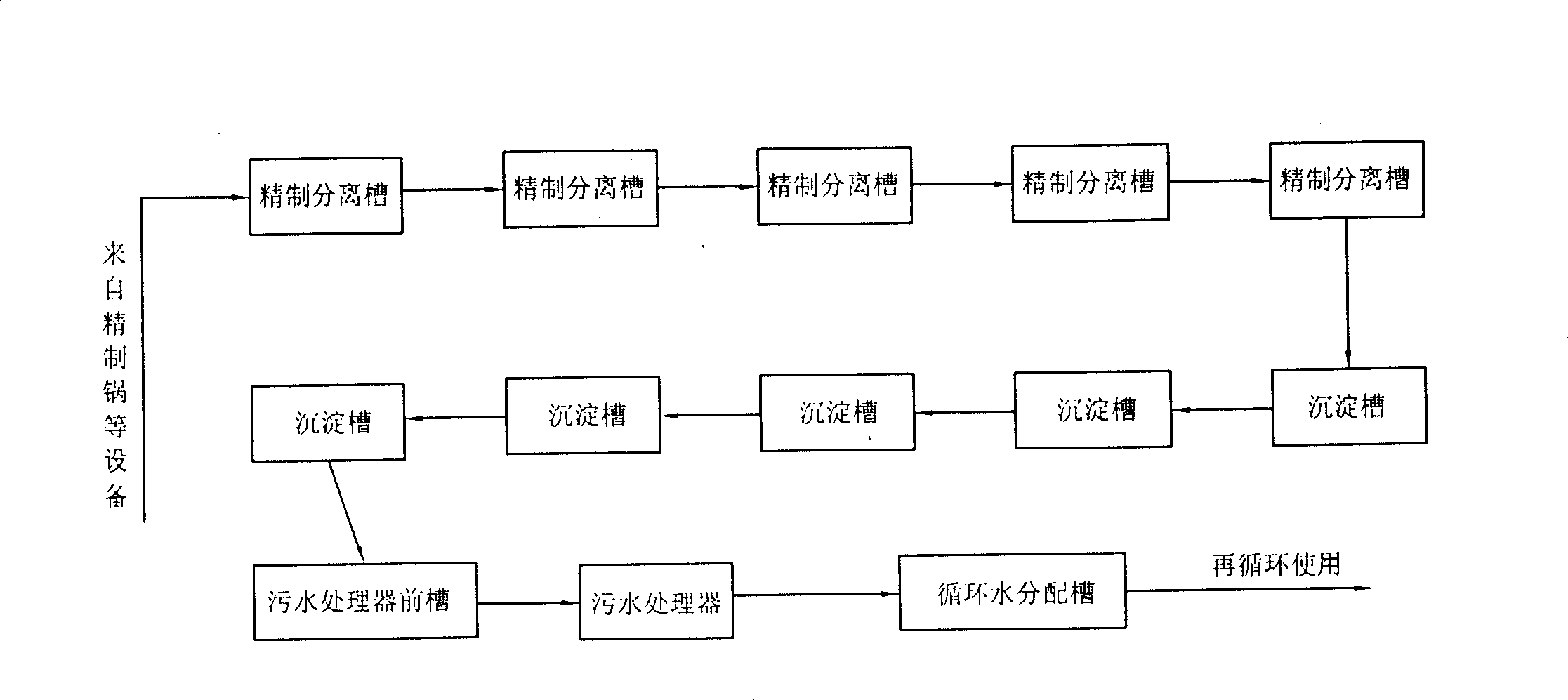

[0014] according to figure 1 The process flow diagram shown in describes the present invention in detail as follows:

[0015] a. The wastewater is transported through pipelines to a sealed separation system connected in series by five refined separation tanks for sedimentation and separation treatment. The floating phosphorus and phosphorus sludge in the wastewater are gradually deposited and separated from the water. During this process, the temperature of the wastewater is guaranteed to be 70 -80°C, use the suction pump to pump the sediment to the refining pot every 24 hours for reuse; after the wastewater passes through five refining and separating tanks in sequence, the phosphorus content in the wastewater is reduced by about 80%;

[0016] b. The wastewater treated by the sealed separation system is introduced into the sedimentation system connected in series by five sedimentation tanks for natural sedimentation and separation. The residual phosphorus sludge in the wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com