Wood plastic micro foaming composite material and its processing shaping method

A composite material and micro-foaming technology, which is applied in the field of wood-plastic micro-foaming composite materials and their processing and molding, to achieve the effects of improved plasticity, low density, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Micro-foamed wood-plastic composites are composed of the following raw materials by mass percentage:

[0035] 100 parts polyvinyl chloride

[0036] Sanding powder 30 parts

[0037] AC (foaming agent) 1.5 parts

[0038] Heat stabilizer 5.0 parts

[0039] 1.8 parts of plasticizer

[0040] Lubricant 1.5 parts

[0041] Foaming aid 5.0 parts

[0042] 2.0 parts of coupling agent

[0043] a. Add polyvinyl chloride resin powder and 100-mesh sanding powder (commercially available industrial products) into SRL-Z200 / 500 high-speed mixer for hot mixing, mix for 5 minutes, weigh heat stabilizer, lubricant, Processing aids such as plasticizers and stabilizers are proportioned according to tribasic lead sulfate: dibasic lead phosphite: lead stearate: barium stearate = 3.0:2.0:1.0:1.0, and added to the mixer , the mixing temperature was 110°C, and the mixing time was 10 minutes. Put the uniformly mixed hot material into the cold mixer and mix it to 40°C; then add the foaming ag...

Embodiment 2

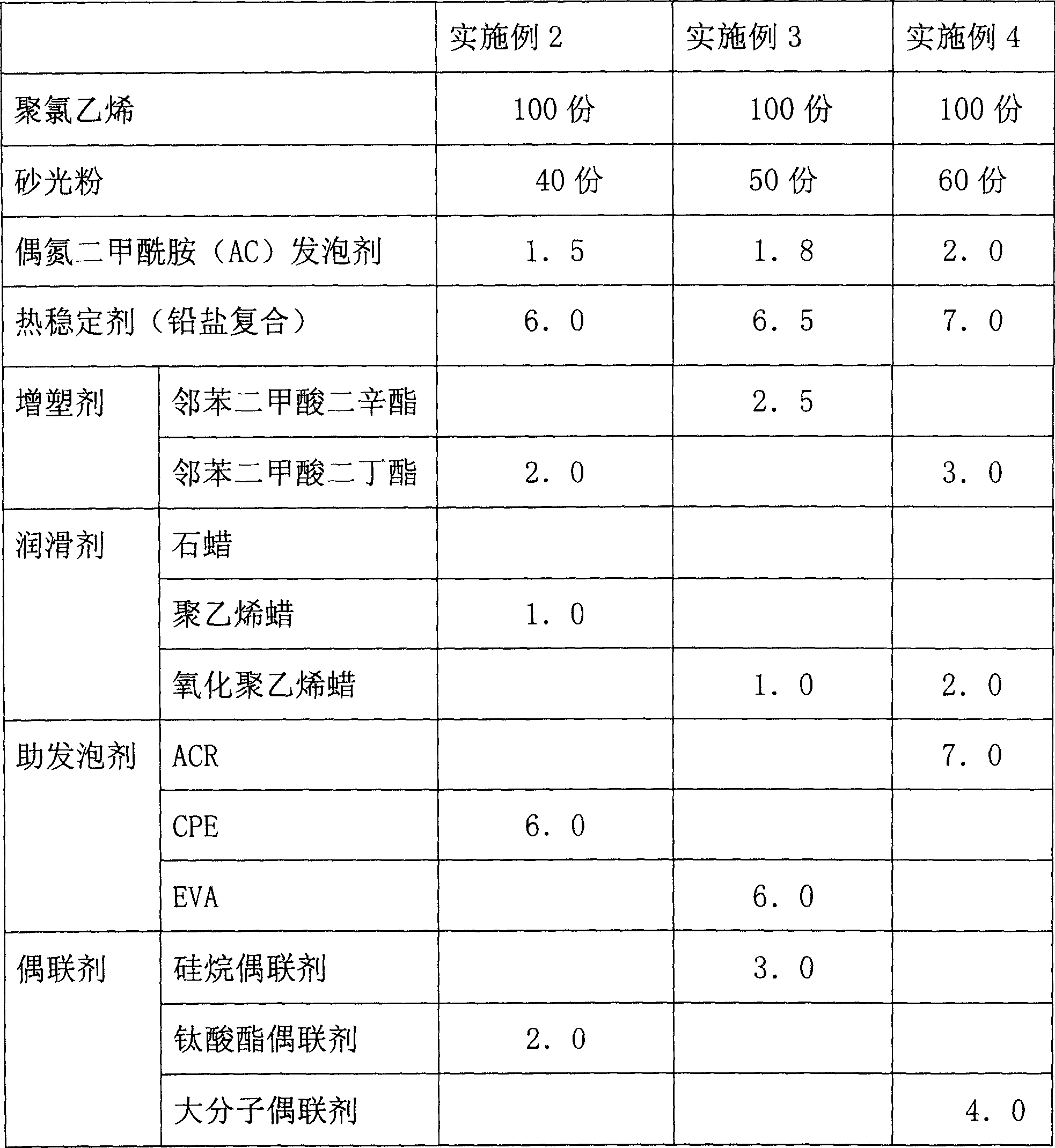

[0046] Embodiment 2, embodiment 3, embodiment 4: process step is the same as embodiment 1, and each component is as table 1:

[0047] Table 1

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com