A TFT LCD array base plate and the manufacturing method thereof

A manufacturing method and array substrate technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of reduced aperture ratio and increased cost, and achieve the effect of reducing the resistance of data lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

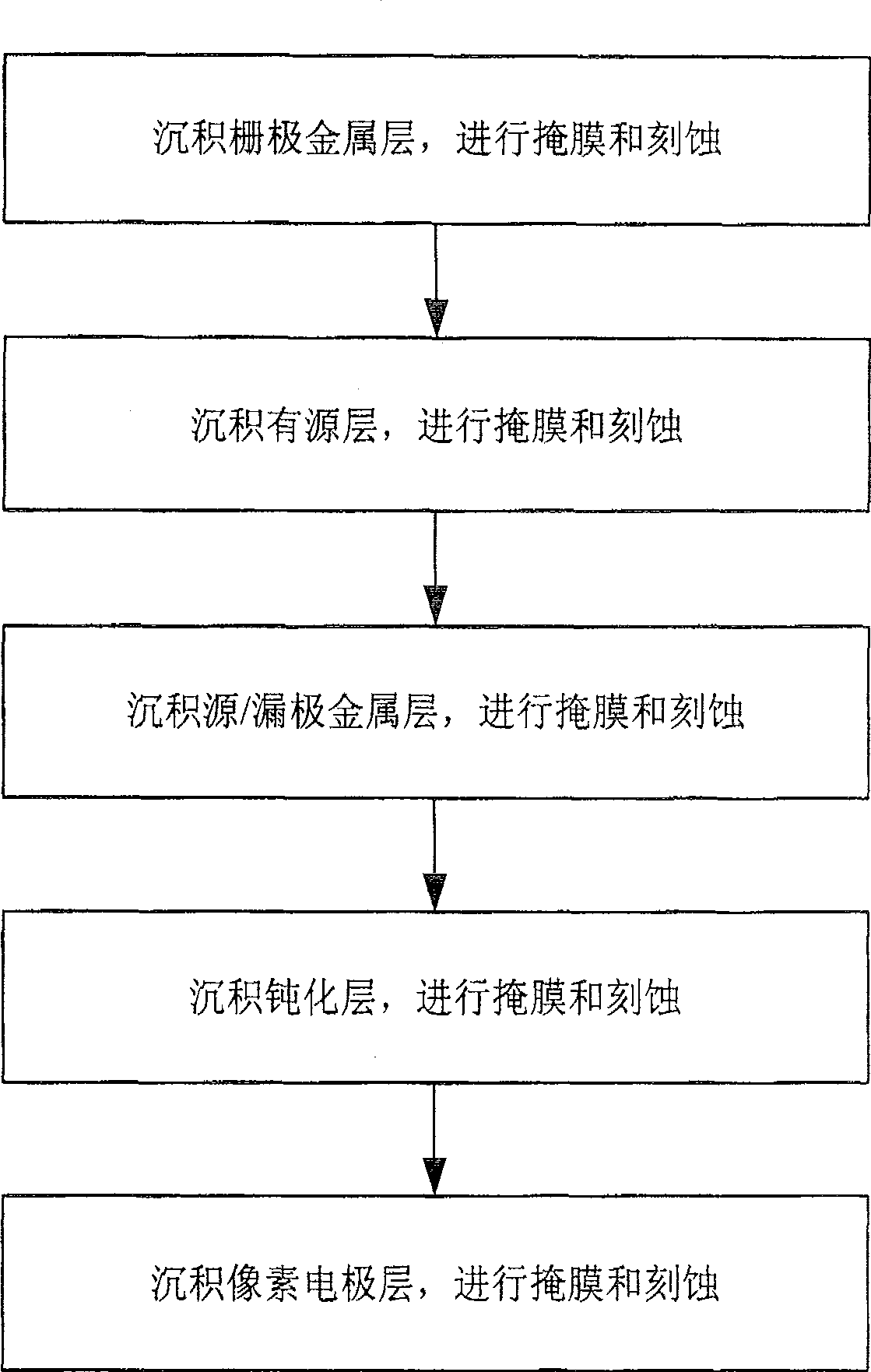

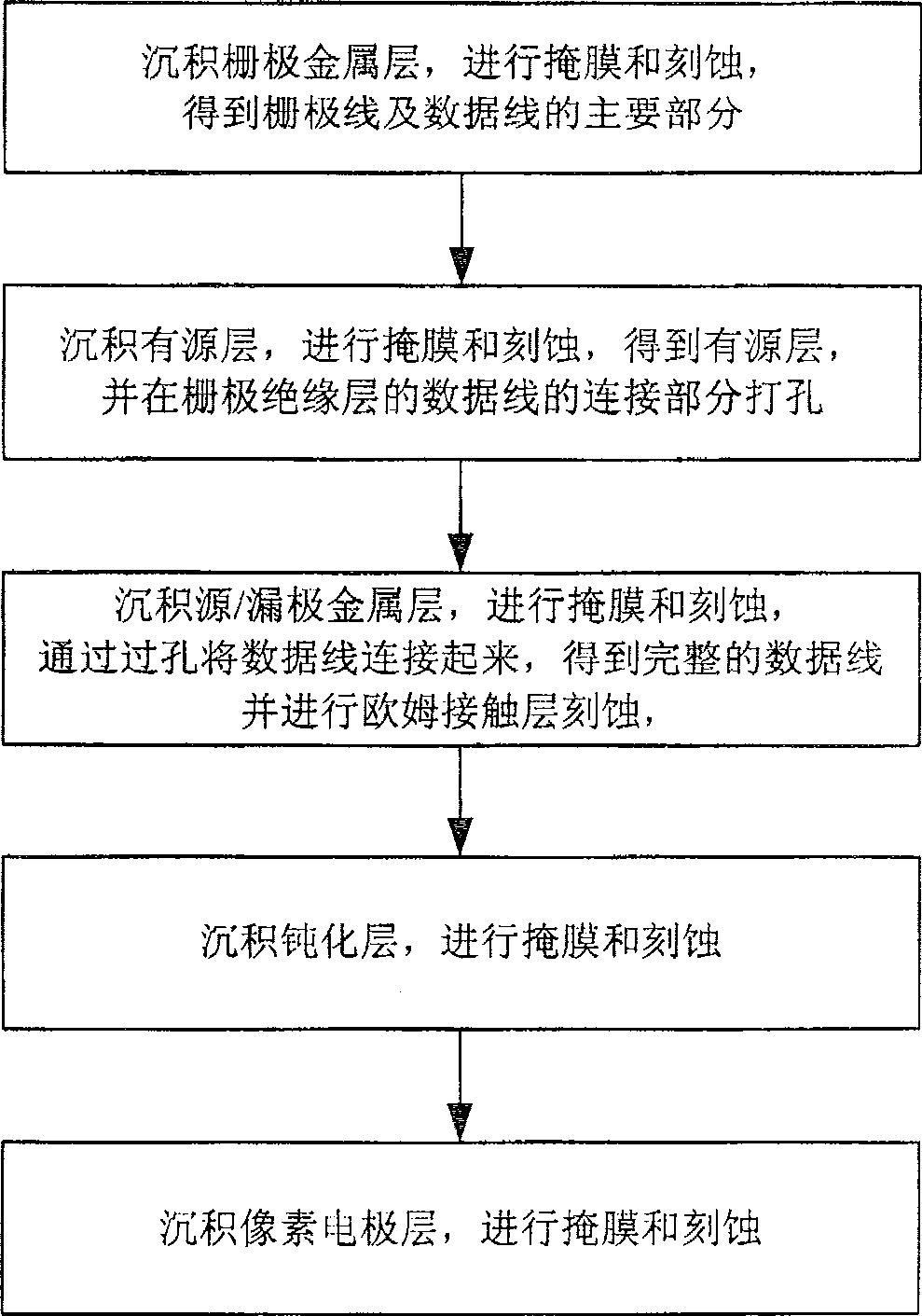

[0035] Such as image 3 Shown, be that the flowchart of the present invention comprises the following steps:

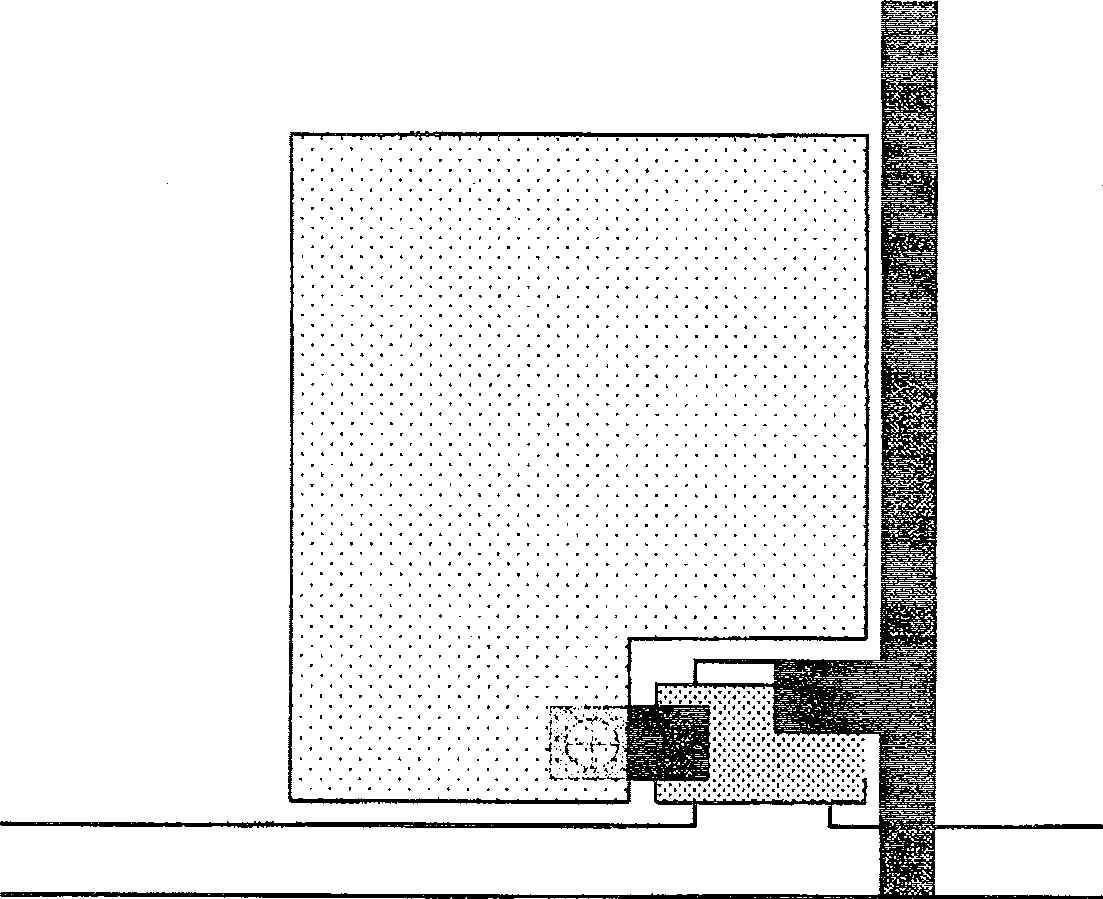

[0036] Step 1. First deposit Gate metal on a clean glass substrate (Bare Glass) by sputtering. Gate metal is a composite film composed of one of AlNd, Al, Cu, Mo, MoW or Cr or any combination of deposition layers. , for example: Mo / AlNd / Mo composite film, AlNd / Mo composite film; then, carry out Gate photolithography, after etching process, get such as Figure 4 The structure shown, along the A-A section as Figure 5 As shown, the gate line and the gate electrode 2, and the main part 3 of the data line are obtained.

[0037]Step 2: Deposit multilayers (MultiLayer) on the substrate formed in step 1 by using chemical vapor phase (PECVD), including one or more insulating dielectric layers such as SiNx, SiOx, SiOxNy, etc., and a-Si active layer and ohmic contact Layer, gray tone active layer mask (G / T Act.Mask) is carried out by using Gray Tone technology, the active la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com