Method for fabricating electric-heating film PTC heating devices

A technology for heating devices and manufacturing methods, applied in electric heating devices, electrical components, ohmic resistance heating, etc., can solve the problems of unsafe use, rise, easy to be damaged, etc., and achieve safe and reliable use, simple process flow, and bonding strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

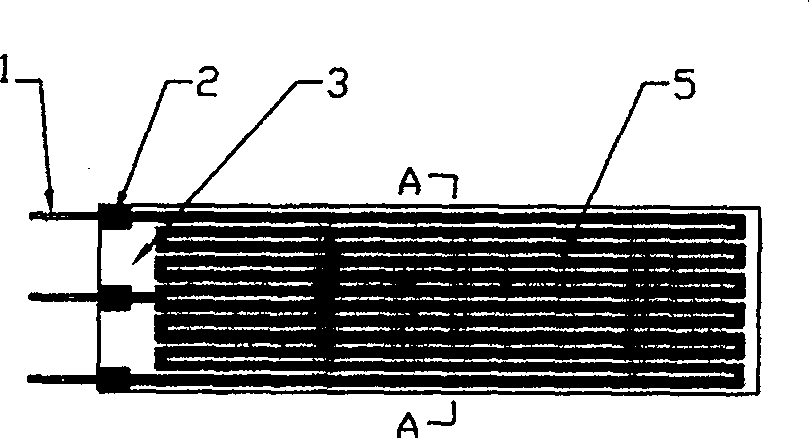

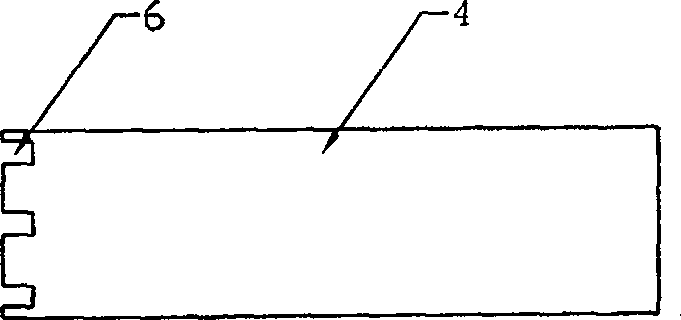

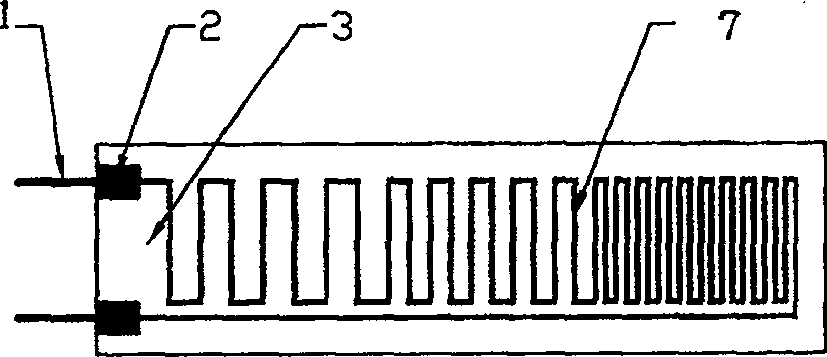

[0043] Firstly, the ceramic substrate green body is made by using the green body casting process: adding an appropriate binder to the alumina ceramic powder, and the alumina used as the raw material of the upper ceramic substrate and the lower ceramic substrate is required to have a content of 96% after sintering . A high-viscosity slurry is formed after ball milling and mixing. The thickness of the casting layer is controlled by a scraper located above the conveyor belt, and a certain thickness of slurry is evenly distributed on the carrier belt when the conveyor belt moves. After drying at 100°C, it is ready for use. This process is prior art. The ceramic substrate green body has a flat surface and a thickness of 0.8mm. as attached figure 1 and 2 As shown in , the ceramic substrate green body in this embodiment has a rectangular structure, and three gaps 6 or two gaps are left on the upper ceramic substrate 4, and the positions of the gaps are directly opposite to the l...

Embodiment 2

[0053] Firstly, the ceramic green body tape-casted with aluminum nitride as the raw material is selected as the ceramic substrate, and the content of aluminum nitride used as the raw material of the upper ceramic substrate and the lower ceramic substrate is required to be 94% after sintering. The green body of the ceramic substrate in this embodiment is a circular flat plate structure, and there are two gaps on the upper ceramic substrate 4, and the positions of the gaps are directly opposite to the lead-out ends of the electrodes 2 of the lower ceramic substrate 3, as shown in the attached Figure 5 And attached Image 6 shown in . The surface of the ceramic substrate green body is flat and the thickness is 1.0mm

[0054] In this example, 60% molybdenum-manganese mixed powder is selected as the electric heating film raw material in the electric heating film slurry screen printing, and 40% glass powder is added, and then mixed with the binder at a ratio of 4:1 . The ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com