Method of producing Cu/NbZr metallic composite tube

A metal composite pipe and alloy pipe technology, applied in metal processing equipment, metal wire drawing, manufacturing tools, etc., can solve the problems of low strength and unfavorable improvement of the density of MgB core wire, etc., and achieve excellent processing performance and good processing plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

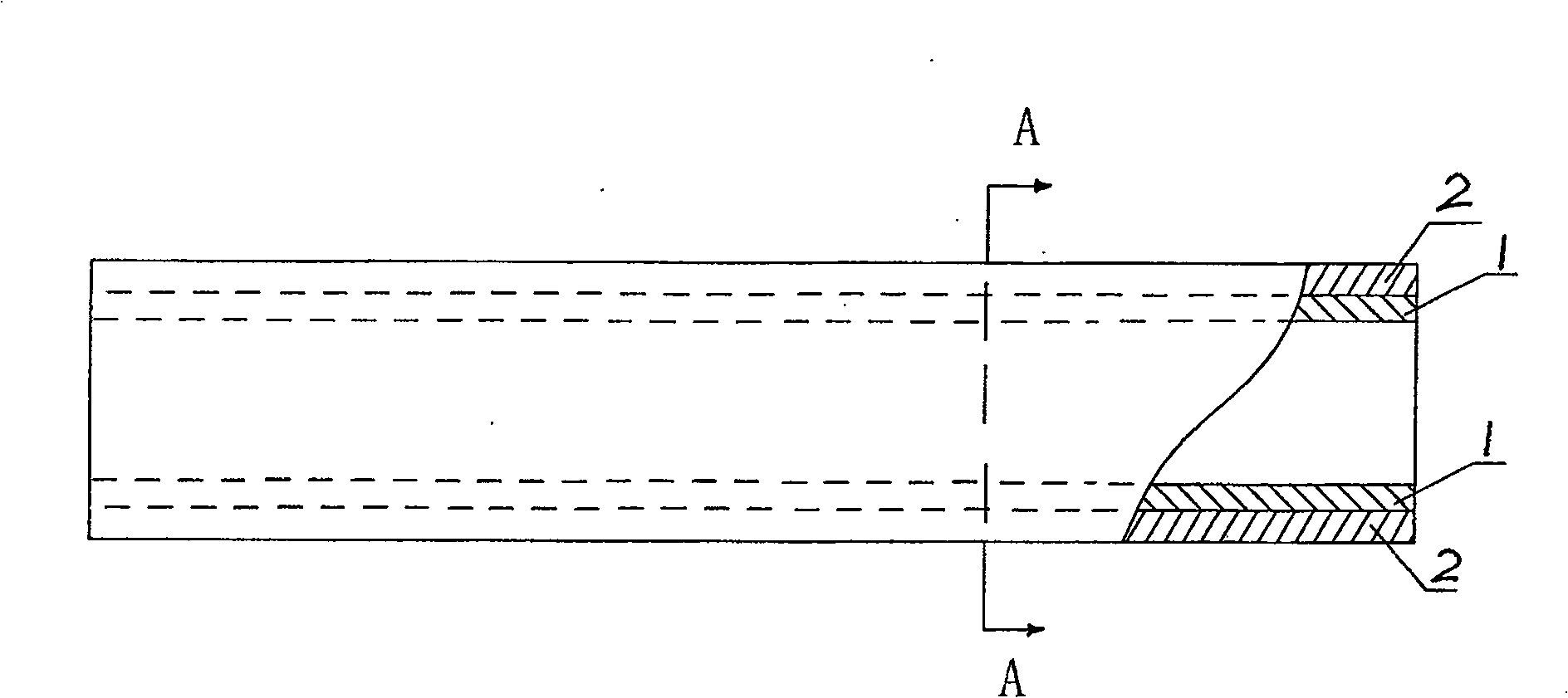

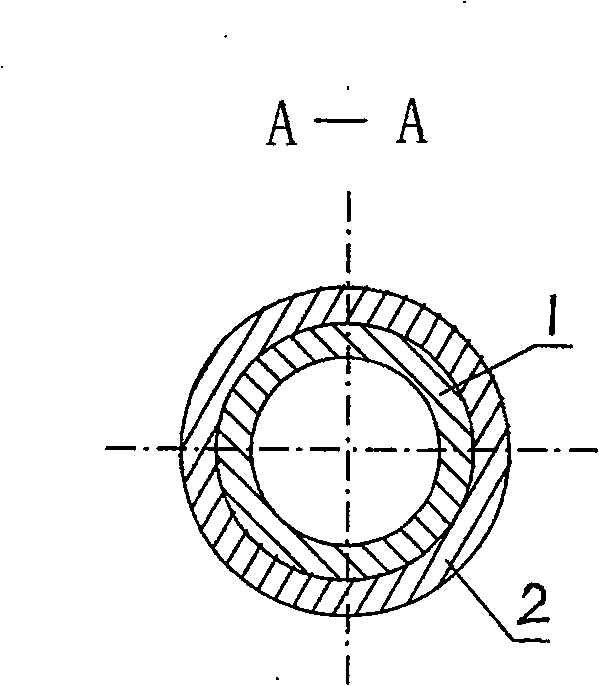

[0013] Firstly, the Nb-5Zr alloy tube with a diameter of Φ8.0×1.0mm is HF:HNO 3 =Pickling in 1:3 hydrofluoric acid and nitric acid solution, Φ11.0×1.4mm Cu tubes were pickled in dilute nitric acid, dehydrated and dried separately, and the Cu tubes were coated on the outer layer of Nb-5Zr tubes. The assembled Cu / Nb-5Zr composite was drawn on a broaching machine with a Φ9.2mm wire drawing die for a single pass at room temperature, and the pass processing rate was 30.05%. The drawn Cu / Nb-5Zr composite pipe is straightened and the head and tail are cut off to obtain a composite sheath material with a size of Φ9.2×2.5mm. Using the composite pipe as the outer sheath material, the kilometer-level magnesium diboride superconducting wire can be prepared by using the in-situ powder casing method.

Embodiment 2

[0015] First, the Nb-1Zr alloy tube with a diameter of Φ12.0×1.5mm is HF:HNO 3 =Pickling in 1:3 hydrofluoric acid and nitric acid solution, pickling Φ16.5×2.0mm Cu tube in dilute nitric acid, drying after dehydration, coating the Cu tube on the outer layer of Nb-1Zr tube. The assembled Cu / Nb-1Zr complex was drawn on a broaching machine with a Φ13.5mm wire drawing die for a single pass at room temperature, and the pass processing rate was 33.06%. Straighten the Cu / Nb-1Zr composite pipe and cut off the head and tail to obtain a composite sheath material with a size of Φ13.5×3.5mm. Using the composite pipe as the outer sheath material, the kilometer-level magnesium diboride superconducting wire can be prepared by using the in-situ powder casing method.

Embodiment 3

[0017] First, the Nb-1Zr alloy tube with a diameter of Φ15.0×2.0mm is HF:HNO 3 =Pickling in 1:3 hydrofluoric acid and nitric acid solution, pickling of Φ20.0×2.4mm Cu tube in dilute nitric acid, drying after dehydration, coating the Cu tube on the outer layer of Nb-1Zr tube. The assembled Cu / Nb-1Zr complex was drawn on a broaching machine with a Φ16.0mm wire drawing die for a single pass at room temperature, and the pass processing rate was 36%. Straighten the Cu / Nb-1Zr composite pipe and cut off the head and tail to obtain a composite sheath material with a size of Φ16.0×4.5mm. Using the composite pipe as the outer sheath material, the kilometer-level magnesium diboride superconducting wire can be prepared by using the in-situ powder casing method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| superconducting critical temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com