Two-stage rotating wheel dehumidification air conditioner device capable of using low-grade heat source

A low-grade heat source, rotary dehumidification technology, applied in household heating, air conditioning systems, applications, etc., can solve the problems of complex structure, inability to remove moisture, difficulty, etc., to meet comfort requirements, significant emission reduction effect, easy to use control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

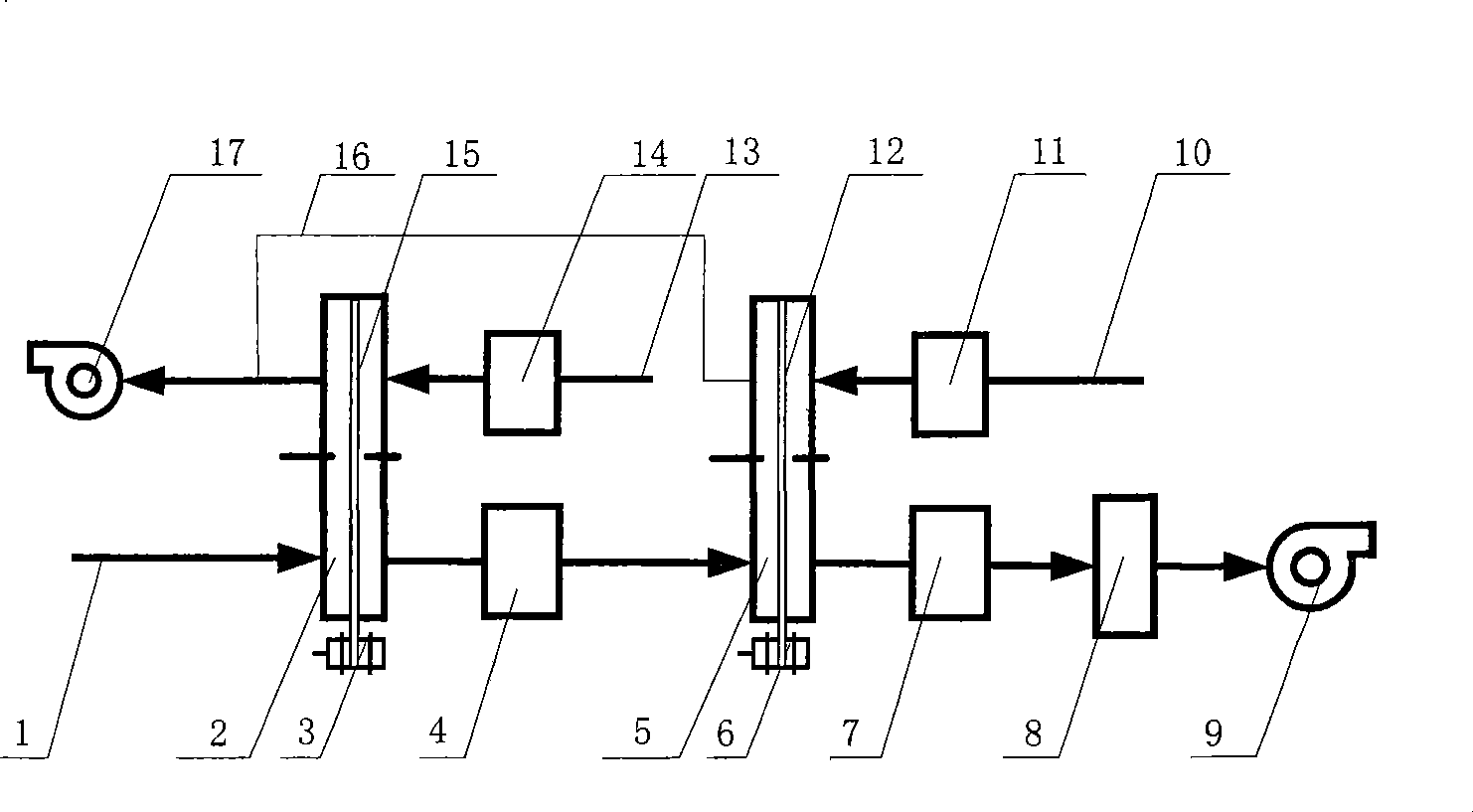

[0032] The structure of this embodiment is as figure 1 As shown, this embodiment includes: a processing air inlet duct 1, a first-stage dehumidification runner 2, a first-stage dehumidification runner drive motor 3, a first-stage treatment heat exchanger 4, a second-stage dehumidification runner 5, Second-stage dehumidification runner drive motor 6, second-stage treatment heat exchanger 7, evaporative cooler 8, treatment fan 9, second-stage regenerative air inlet duct 10, second-stage regenerative heater 11, second-stage dehumidification Wheel drive belt 12, first stage regenerative air inlet air duct 13, first stage regenerative heater 14, first stage dehumidification runner drive belt 15, second stage regenerative air outlet air duct 16, regenerative fan 17.

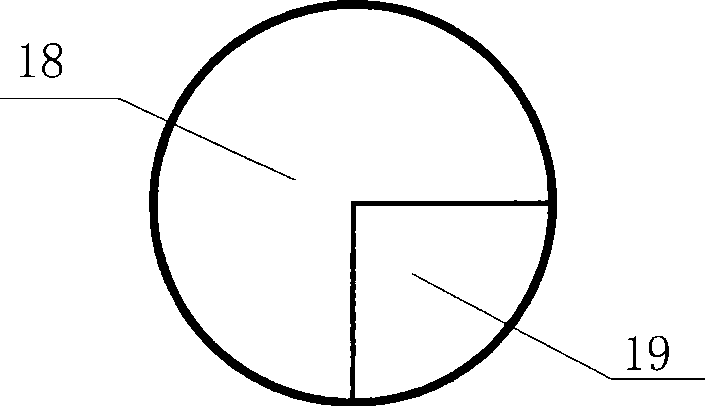

[0033] Such as figure 2 As shown, the first-stage dehumidification rotor 2 treatment zone 18 and regeneration zone 19 account for 3 / 4 and 1 / 4 of the cross-sectional area of the rotor respectively, and other ratios,...

Embodiment 2

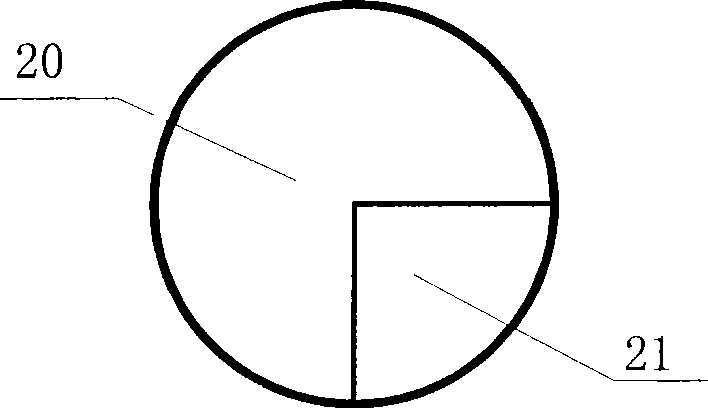

[0044] The structure of this embodiment is as Figure 4 As shown, the two-stage dehumidification air conditioner includes: processing air inlet duct 1, first-stage dehumidification rotor 2, first-stage dehumidification rotor drive motor 3, first-stage treatment regenerator 22, second-stage dehumidification rotor Wheel 5, second-stage dehumidification wheel drive motor 6, second-stage treatment regenerator 23, evaporative cooler 8, treatment fan 9, second-stage regenerative air inlet duct 10, second-stage regenerative heater 11, second-stage regenerator Second-stage dehumidification wheel drive belt 12, first-stage regeneration air inlet duct 13, first-stage regeneration heater 14, first-stage dehumidification wheel drive belt 15, second-stage regeneration air outlet duct 16, regeneration fan 17 , the regeneration air inlet main pipe 24, and the regeneration side evaporative cooler 25. figure 2 , image 3 It is a schematic diagram of the first-stage dehumidification rotor 2 ...

Embodiment 3

[0054] The structure of this embodiment is as Figure 5 shown. Compared with Example 2, the structure of this embodiment has no evaporative cooler on the regeneration side and is only used for heating in winter.

[0055] Compared with Embodiment 2, the difference in its connection method is:

[0056] The treatment air passes through the treatment side outlet of the first-stage treatment regenerator 22 and is connected with the treatment blower 9 through the air duct 27 . The second-stage treatment air inlet pipe 26 is connected to the air inlet side of the treatment area of the second-stage dehumidification rotor 5, and the air outlet side of the treatment area of the second-stage dehumidification rotor 5 is treated with the second-stage treatment regenerator 23 through the air duct. The side inlets are connected, and the second-stage treatment regenerator 23 is connected to the evaporative cooler 8 through an air pipe. The evaporative cooler 8 is connected with the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com