Compound corn chip

A technology of corn flakes and corn, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of backward technology and forming methods, single taste of corn flakes, and low nutritional content, and achieve high toughness, good molding, and nutritional value. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

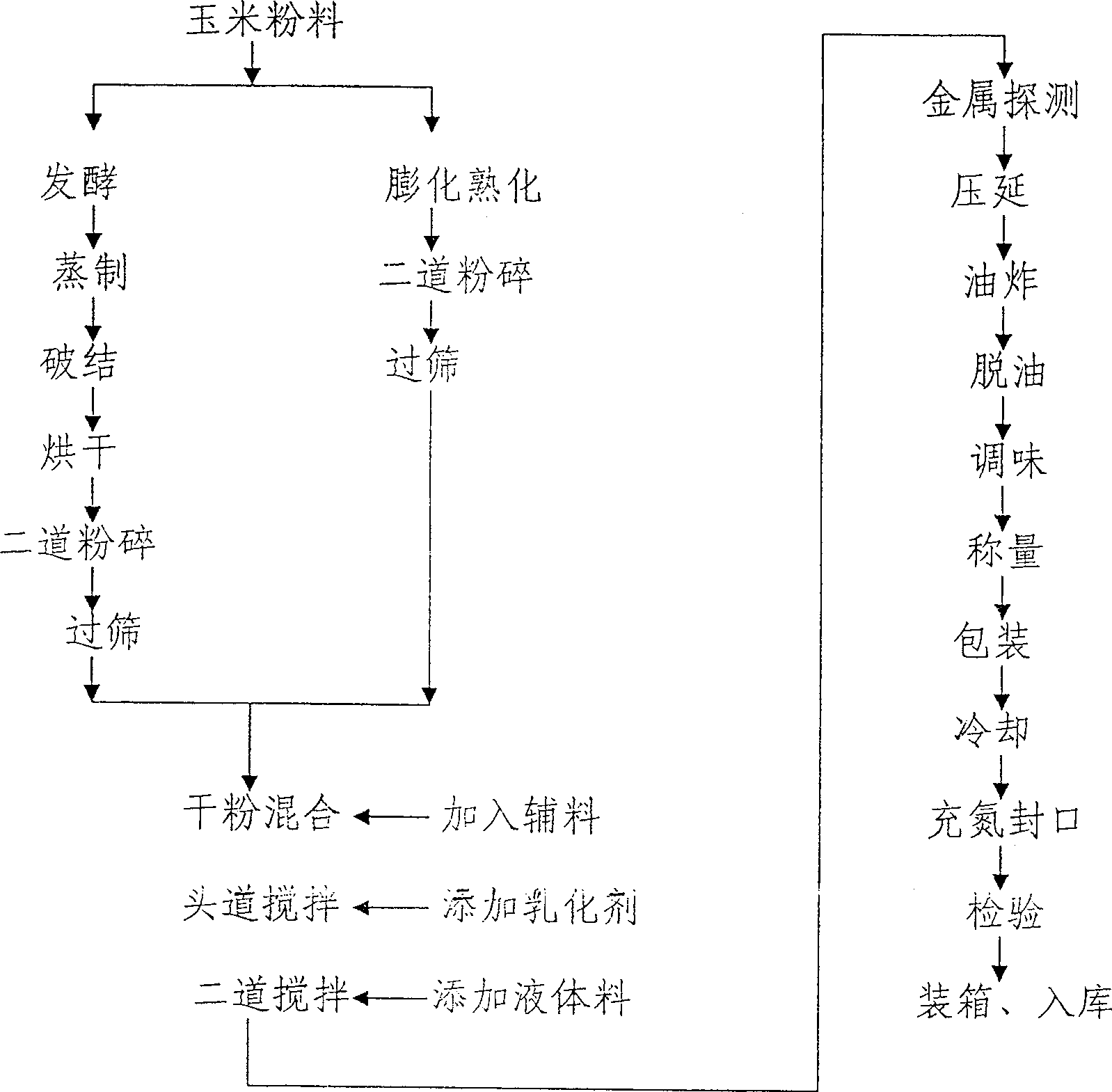

[0025] see figure 1 , the preparation steps of the composite corn flakes are as follows:

[0026] 1), the preparation of dry powder raw material:

[0027] ①. Preparation of cooked corn flour:

[0028] Get 50 kilograms of raw corn powders and extrude and puff them in a conventional way and crush them to 95% to pass through a 200 mesh sieve, and form cooked corn flour with the remaining coarser flour for subsequent use;

[0029] ②. Preparation of corn fermentation powder:

[0030] a, select 50 kilograms of raw corn flour that has crossed a 60-mesh sieve, add 0.75 kilograms of yeast and 50 kilograms of water to ferment;

[0031] b. Steam the fermented raw corn flour for 60 minutes to fully gelatinize the starch;

[0032] c. Properly break the lumped corn flour after steaming and gelatinization, and then dry it in two stages at 60-65°C for 1 hour, and at 50-55°C for 4 hours until the moisture content is 15. ~18%;

[0033] d, pulverize the above-mentioned dried corn flour, th...

Embodiment 2

[0043] The preparation steps and the values of the raw materials in this embodiment are exactly the same as those in the previous embodiment. The difference is that to prepare corn fermentation powder, add 1 kg of yeast and 55 kg of water for fermentation; steam the fermented raw corn flour for 50 minutes in time to fully gelatinize the starch; The shaped corn flour is properly broken, and then dried in two stages at 60-65°C for 1.5 hours and 50-55°C for 3 hours until the water content is 15-18%; the mixing ratio of dry powder is:

[0044] Cooked corn flour: corn fermentation powder: potato flake powder: modified starch: wheat starch: corn starch: soybean flour: dextrin: lecithin: whey powder = 25:25:32:3.5:2.5:6:3:1.5: 0.25:0.25;

[0045] The emulsifier added by the first stirring is:

[0046]Take 100 kg of the above-mentioned mixed dry powder and transport it into a high-speed mixer, add 2 kg of glycerol monostearate melted into a liquid state by spraying while stirring,...

Embodiment 3

[0051] The preparation steps of the present embodiment and the value of the corn flour raw material are exactly the same as those of the first two embodiments. The difference is that the preparation of corn fermentation powder adds 0.75 kg of yeast and 55 kg of water for fermentation; the fermented raw corn flour is steamed in a steamer for 55 minutes in time to fully gelatinize the starch; The shaped corn flour is properly broken, and then dried in two stages at 60-65°C for 1.3 hours and 50-55°C for 3.5 hours until the water content is 15-18%; the mixing ratio of dry powder is:

[0052] Cooked corn flour: corn fermented powder: potato flour: modified starch: wheat starch: corn starch: soybean flour: dextrin: lecithin: whey powder = 20.9: 26: 32: 3: 2: 6: 1.5: 2: 0.2∶0.2;

[0053] The emulsifier added by the first stirring is:

[0054] Take 100 kg of the above-mentioned mixed dry powder and transport it into a high-speed mixer, add 1 kg of glyceryl monostearate melted into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com