Cooking oil smoke degradation conversion device

A conversion device and oil fume technology, applied in the direction of oil fume removal, chemical instruments and methods, household heating, etc., can solve the problems of secondary pollution equipment stain removal, incompleteness, mechanical noise, etc., to achieve uniform degradation temperature, good Degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

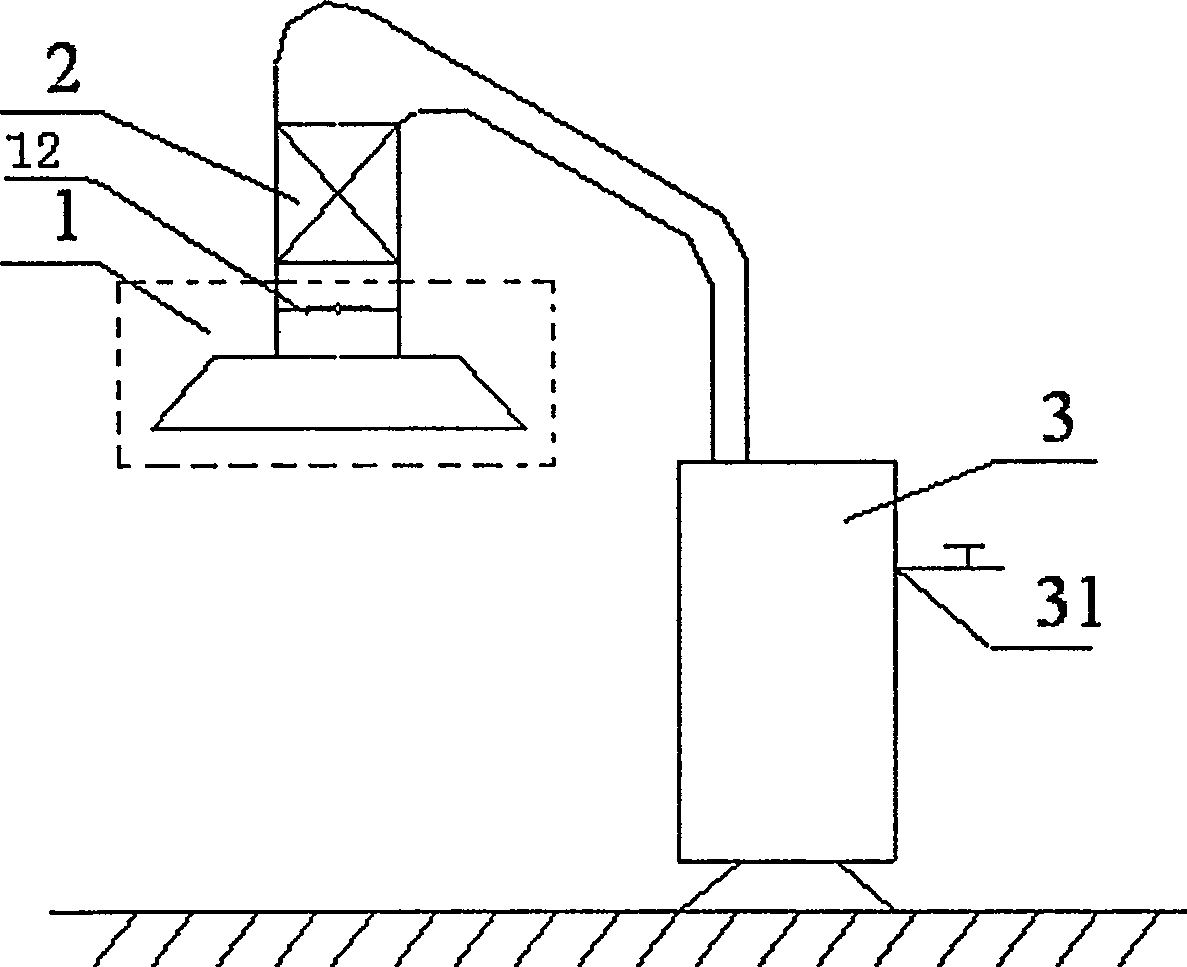

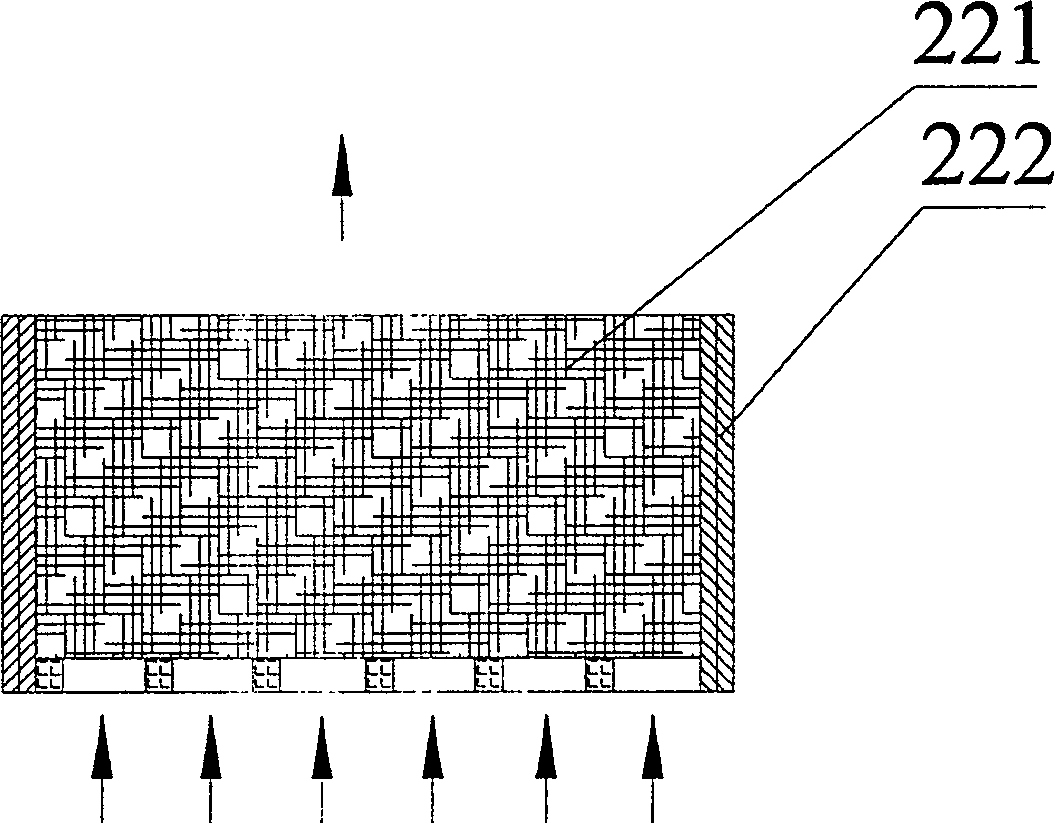

[0015] Example 1 A cooking oil fume degradation conversion device for treating cooking oil fume, comprising a oil fume extractor 1, a through-type oil fume degrader 2 is provided on the oil fume flow channel formed by the oil fume extractor 1, and a through-type oil fume degrader The outlet 21 of the device 2 is communicated with the storage tank 3, and the upper part of the storage tank 3 is provided with a combustible gas outlet 31). A heating resistance wire 222 is arranged around the kaolin clay copper oxide degradation block 221 .

Embodiment 2

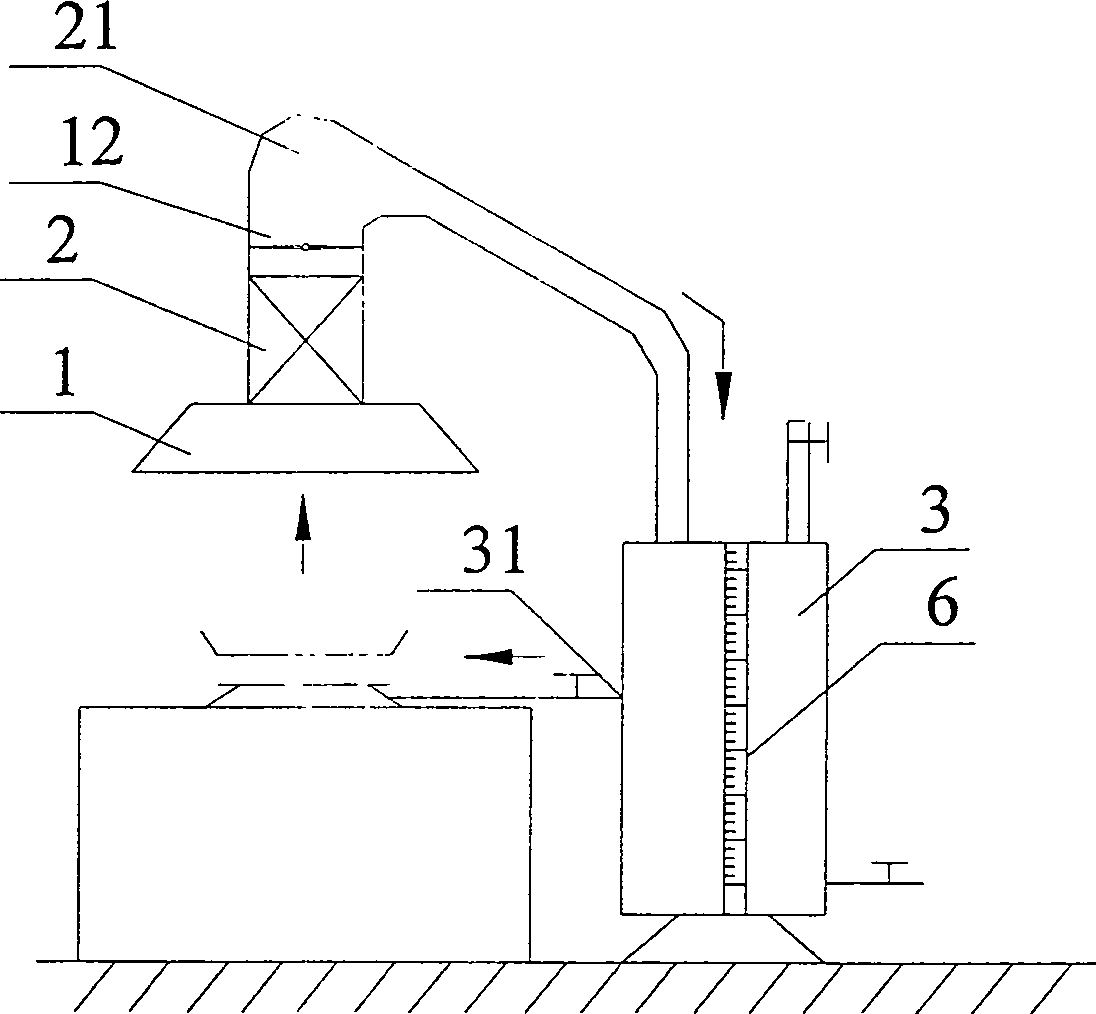

[0016] Example 2 A cooking oil fume degradation conversion device for treating cooking oil fumes, including a oil fume extractor 1, a through-type oil fume degrader 2 is provided on the oil fume flow channel formed by the oil fume extractor 1, and a through-type oil fume degrader The outlet 21 of the device 2 is connected with the storage tank 3, and the upper part of the storage tank 3 is provided with a combustible gas outlet 31, and a heating resistance wire 222 is provided in the reticulated kaolin copper oxide degradation block 221, and the through-type oil fume degrader 2 is made of kaolin The copper oxide degradation rod 232 is composed of a kaolin copper oxide degradation rod 232 with a heating resistance wire 231.

[0017] The present invention realizes the pollution-free treatment of cooking oil fume based on the following principle: the present invention makes the cooking oil fume in contact with the kaolin copper oxide degradation block undergo oxidation reaction, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com