A kind of composite water-based adhesive formed by polypeptide and glycyrrhizic acid and preparation method thereof

A technology of glycyrrhizic acid and adhesives, applied in the field of materials, can solve problems such as high heavy metal content, loss of viscosity, and potential safety hazards, and achieve the effects of easy degradation, easy formation, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a method for preparing the polypeptide / glycyrrhizic acid composite aqueous adhesive of the above technical solution, comprising the following steps:

[0042] The pH value of the glycyrrhizic acid aqueous solution is adjusted to 6.0-8.0 with a 0.01-0.1 mol / L sodium hydroxide aqueous solution to obtain a glycyrrhizic acid precursor solution;

[0043] Adjust the pH value of the polypeptide aqueous solution to 6.0-8.0 with 0.01-0.1 mol / L sodium hydroxide aqueous solution to obtain the polypeptide precursor solution;

[0044] Mix the polypeptide precursor solution and the glycyrrhizic acid precursor solution, control the charge ratio of the polypeptide to the glycyrrhizic acid to be 1-1.2:1, stir evenly at 22-25°C, and stand at room temperature for 0.5-1h to obtain the polypeptide / licorice Acid complex water-based adhesive.

[0045] In the present invention, the polypeptide and the glycyrrhizic acid are respectively dissolved in double distill...

Embodiment 1

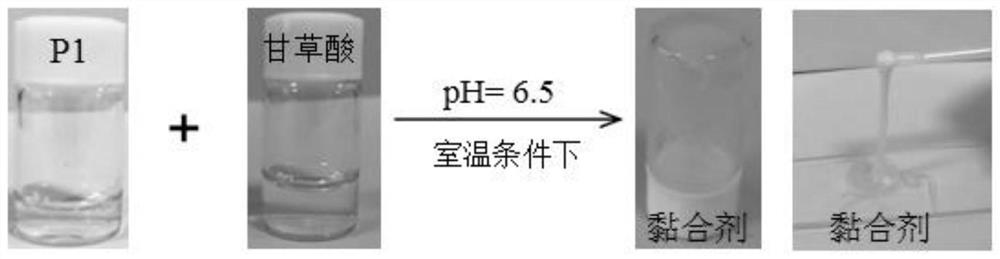

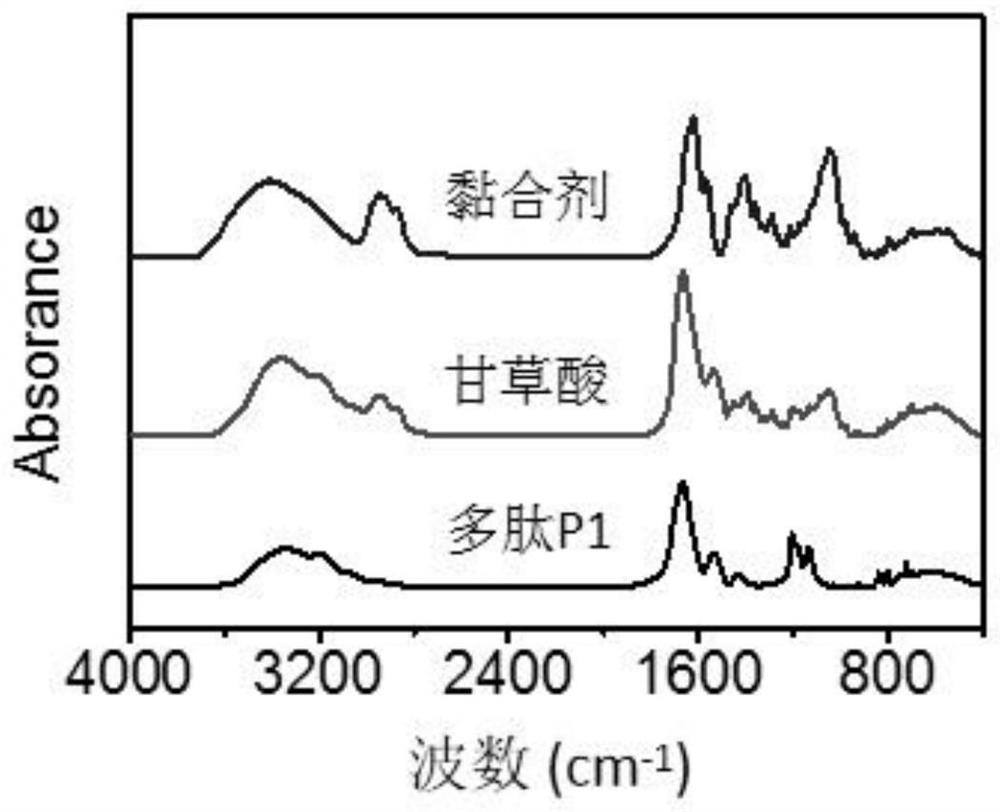

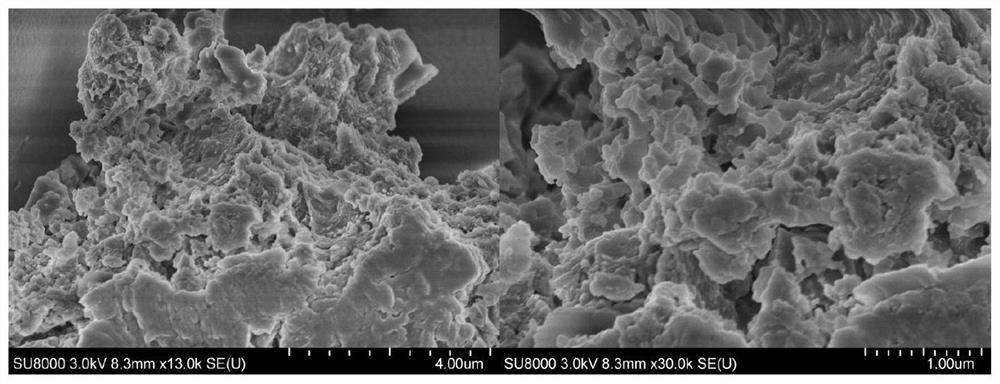

[0049] 1) Preparation of polypeptide P1 / glycyrrhizic acid composite aqueous adhesive: Dissolve 100 mg of polypeptide (P1: molecular weight of 1220.34 g / mol) in 0.5 mL of double distilled water, and adjust the pH of the solution with 0.1 mol / L sodium hydroxide. 7.3, obtaining a polypeptide precursor. 67.43 mg of glycyrrhizic acid (molecular weight: 822.93 g / mol) was dissolved in 0.5 mL of double distilled water, and the pH of the solution was adjusted to 6.5 with 0.1 mol / L NaOH. At 25°C, the aqueous solution of glycyrrhizic acid was added dropwise to the aqueous solution of polypeptide P1, and the transparent solution gradually turned into a turbid state. The obtained mixed solution was stirred at 25°C for 0.5 h after being stirred by a vortex, and the solution turned from turbid to transparent. During this process, a milky white composite aqueous adhesive was gradually formed at the bottom of the solution.

[0050] 2) Performance test:

[0051] 1) figure 1 It is the digital...

Embodiment 2

[0075] As shown in Example 1, with other conditions unchanged, 100 mg of polypeptide P1 was changed to 100 mg of polypeptide P2 (AC-RRYNYQRR-NH 2 , the molecular weight is 1252.38g / mol), and the composite water-based adhesive is prepared according to the above method. Then, the adhesive property, tensile property, self-healing ability and rheological behavior of the composite water-based adhesive were tested according to the steps of Example 1. The bonding test of the composite water-based adhesive to solid materials such as polypropylene, polyether ether ketone, polycarbonate, titanium, stainless steel, wood, shell, stone, rubber, agate) shows that the composite water-based adhesive prepared has a wide range of performance. The adhesive properties of the spectrum. The tensile shear strength of polypeptide P2 / glycyrrhizic acid composite water-based adhesive to titanium, stainless steel, polyetheretherketone, polypropylene and pigskin in water environment are 55.1±1.5kPa, 30.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com