Process for deodorizing household garbage, increasing methane yield and accelerating garbage degradation

A technology for the degradation of domestic waste and garbage, applied in the removal of solid waste, waste treatment, waste fuel, etc., can solve the problems of air pollution, low treatment efficiency, volatile escape, etc., to accelerate the degradation rate and increase the production of methane , the effect of improving the degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

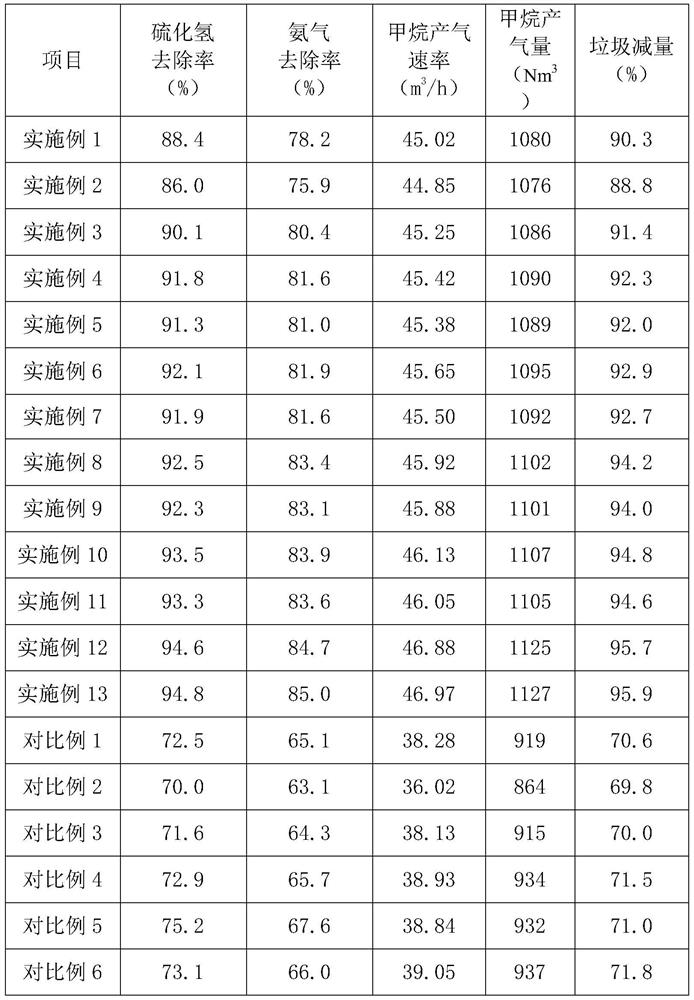

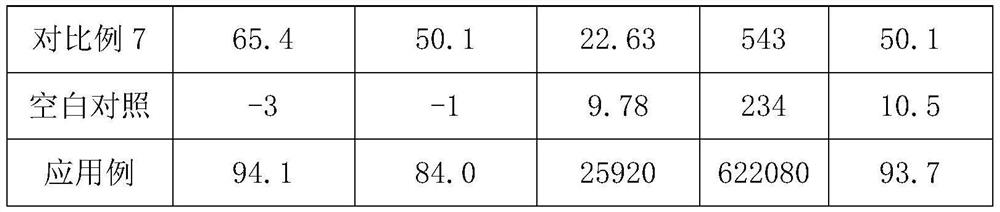

Examples

preparation example 1

[0044] This preparation example discloses a microbial inoculum, which includes bacillus, lactic acid bacteria, streptococcus thermophilus, red yeast, photosynthetic bacteria and actinomycetes.

[0045] This preparation example also discloses a manufacturing method of a microbial inoculum, which specifically includes:

[0046] S1, after the Bacillus, Lactobacillus, Streptococcus thermophilus, Rhododendron, Photosynthetic and Actinomycete strains were respectively activated and cultured in solid state, the obtained concentrations were all 1×10 8 CFU / ml of Bacillus bacteria suspension seed liquid, Lactobacillus bacteria suspension seed liquid, Streptococcus thermophilus bacteria suspension seed liquid, Rhododendron bacteria suspension seed liquid, Photosynthetic bacteria bacteria suspension seed liquid and Actinomycete bacteria suspension liquid seed liquid;

[0047] S2, respectively inoculate the above-mentioned bacterial suspension seed liquid with 5% of the inoculum to the PD...

preparation example 2

[0050] This preparation example discloses a method for producing a microbial inoculum. The difference between this preparation example and preparation example 1 is that the component distribution ratio of each bacterial suspension in S3 is different, specifically: 12kg of Bacillus bacteria suspension, 1.2kg Lactic acid bacteria suspension, 1kg Streptococcus thermophilus bacteria suspension, 1kg Rhododendron bacteria suspension, 1kg photosynthetic bacteria bacteria suspension and 1.5kg actinomycete bacteria suspension were mixed and added into the stirring pot, and stirred at a uniform speed of 120r / min. 20min to obtain microbial inoculum.

preparation example 3

[0052] This preparation example discloses a manufacturing method of a microbial inoculum. The difference between this preparation example and preparation example 1 is that the composition ratio of each bacterial suspension in S3 is different, specifically: 10kg of Bacillus bacteria suspension, 1kg of lactic acid bacteria Bacterial suspension, 1kg of Streptococcus thermophilus bacterial suspension, 1kg of Rhodotorula bacterial suspension, 1kg of photosynthetic bacteria bacterial suspension and 1kg of Actinomycetes bacterial suspension were mixed into the stirring pot, and stirred at a uniform speed of 120r / min for 20min. Obtain microbial inoculum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com