Process for treating gas water for producing gas by lurgi furnace

A treatment method, gas water technology, applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve problems such as poor filtering effect of dual-media filters, high ammonia content in gas water, clogged filter beds, etc., to achieve The effect of changing the appearance of the working environment, increasing the reuse rate, and advanced indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

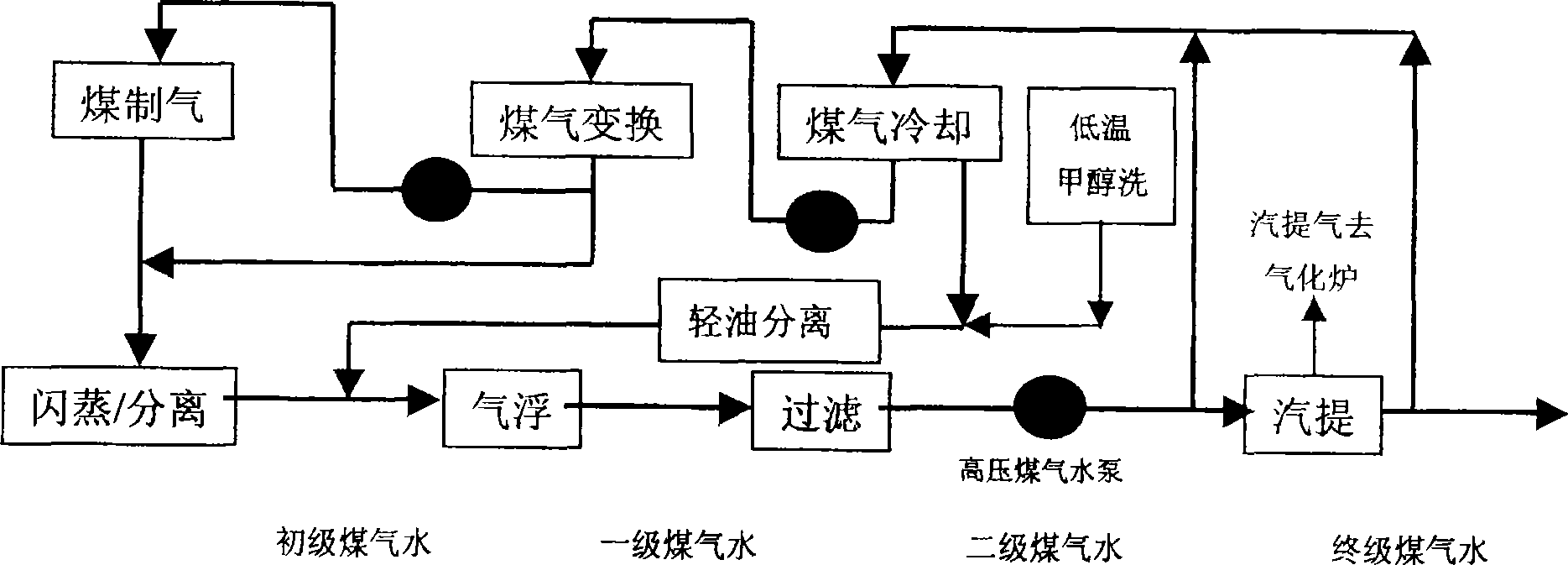

[0029] In order to meet the requirements of today's environmental protection for gas and water treatment, combined with the demand for 50% expansion of the Luqi coal-to-ammonia plant, Tianji Coal Chemical Group Co., Ltd. has improved the raw gas and water treatment process of the Luqi furnace coal-to-gas plant. , Created the Lurgi furnace coal-to-gas gas-water comprehensive treatment new process of the present invention. The following combination figure 2 The process flow chart for a detailed description:

[0030] The high-pressure gas water from the coal-to-gas section and the conversion section, after heat recovery, is flashed to remove dissolved gas through the flash / separation unit, and the degassed gas water enters the tar separator to remove solid substances to obtain primary gas water. The tar separation unit consists of two sets of tar primary separator and tar secondary separator connected in series to prolong the residence time of gas water and fully separate tar; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com