Device and system for feeding large bio-material to furnace for directly burning generating

A technology of combustion power generation and material delivery system, applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve problems that have not been seen yet, achieve the effect of maintaining normal and stable combustion, facilitating promotion, and overcoming disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

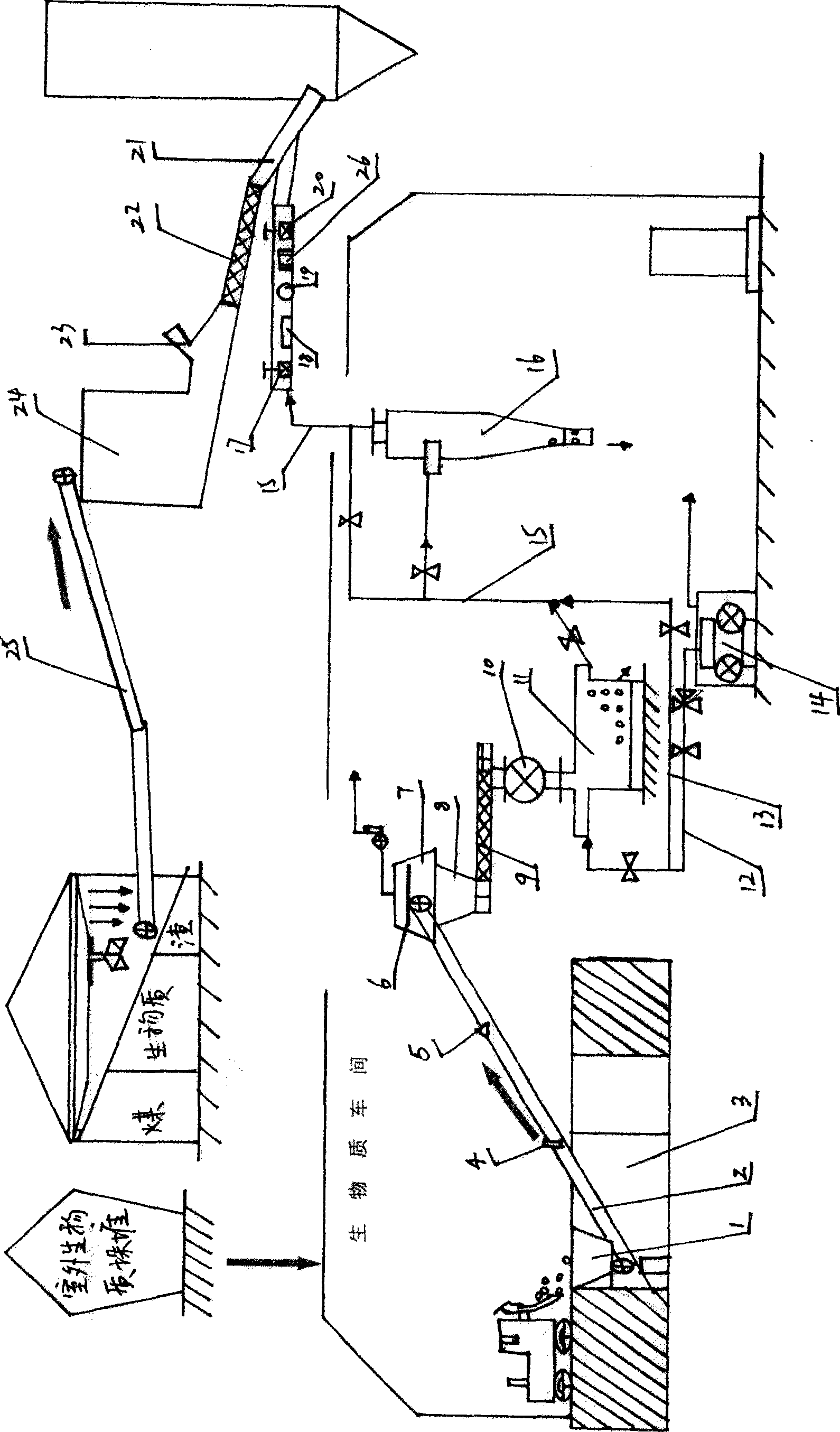

Embodiment 1

[0031] Example 1. A material delivery method for transporting a large amount of biomass into the furnace for direct combustion to generate electricity. The biomass raw material is processed and cut into short biomass rods, or the shell and chip biomass raw materials are directly taken, and the gas composed of biomass raw materials and wind is used by wind The solid and two-phase mixture flows through the conveying pipeline, and is directly sent to the dense-phase area in the fluidized bed boiler for combustion and power generation. During the process of conveying the biomass by wind, it is also treated for removing mud and sand.

Embodiment 2

[0032] Example 2. A material delivery method for transporting a large amount of biomass into the furnace for direct combustion to generate electricity. The biomass raw material is processed and cut into short biomass rods, or the shell and chip biomass raw materials are directly taken, and the gas composed of biomass raw materials and wind is used by wind The solid and two-phase mixture flows through the conveying pipeline, and is directly sent to the dense-phase area in the fluidized bed boiler for combustion and power generation. During the process of conveying the biomass by wind power, it is also treated to remove silt and sand debris; the processed and cut biomass The length of the short rod is 40mm; at the same time, the iron removal treatment is also carried out on the biomass raw material.

Embodiment 3

[0033] Example 3. A material delivery method for transporting a large amount of biomass into the furnace for direct combustion to generate electricity. The biomass raw material is processed and cut into short biomass rods, or the shell and chip biomass raw materials are directly taken, and the gas composed of biomass raw materials and wind is used by wind The solid and two-phase mixture flows through the conveying pipeline, and is directly sent to the dense-phase area in the fluidized bed boiler for combustion and power generation. During the process of conveying the biomass by wind power, it is also treated to remove silt and sand debris; the processed and cut biomass The length of the short rod is 20mm; at the same time, the iron removal treatment is also carried out on the biomass raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com