Method for decreasing petroleum acid value

A technology of petroleum acid and petroleum, applied in the field of deacidification, which can solve the problems of affecting the properties of petroleum and high cost, and achieve the effect of avoiding the influence of petroleum properties, easy implementation and high deacidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is used to illustrate the method for reducing the acid value of petroleum provided by the present invention.

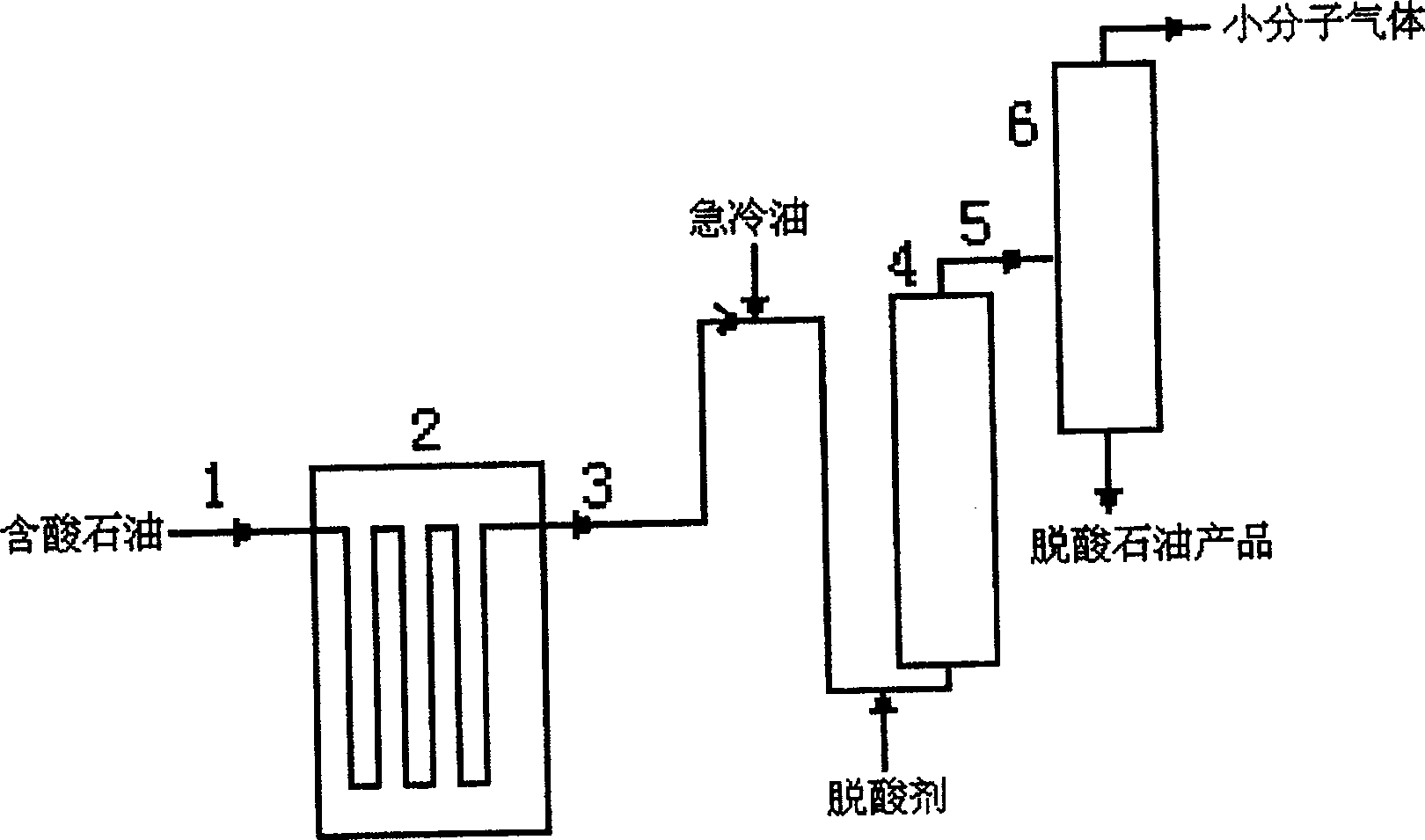

[0035] Such as figure 1 As shown, the desalted and dehydrated crude oil with an acid value of 18.21 mg KOH / g enters the preheater 2 from pipeline 1 and preheats to 440 ° C for thermal deacidification reaction. The time of thermal deacidification reaction is 30 seconds, and the obtained heat The deacidification reaction product is cooled to 250°C in pipeline 3 by heat exchange with diesel oil at 50°C, and then sent into esterification reactor 4 together with 0.5% by weight of glycerol and 0.8% by weight of pentaerythritol relative to the weight of desalted and dehydrated crude oil Carry out esterification and deacidification reaction, the reaction time is 200 minutes, the obtained esterification and deacidification product enters fractionation tower 6 from pipeline 5 and carries out fractional distillation, and the deacidification crude oil produ...

Embodiment 2

[0037] This embodiment is used to illustrate the method for reducing the acid value of petroleum provided by the present invention.

[0038] Such as figure 1 As shown, the desalted and dehydrated crude oil with an acid value of 10.36 mg KOH / g enters the preheater 2 from pipeline 1 and preheats to 420 ° C for thermal deacidification reaction. The time of thermal deacidification reaction is 50 seconds, and the obtained heat The deacidification reaction product is cooled to 300°C in the pipeline 3 through heat exchange with 30°C diesel oil, and then sent to the esterification reactor 4 together with 0.5% by weight of diethylene glycol relative to the weight of the desalted and dehydrated crude oil for deesterification Acid reaction, the reaction time is 30 minutes, the obtained esterification and deacidification product enters the fractionation tower 6 from pipeline 5 for fractionation, and obtains deacidification crude oil product, small molecular gas and coke with an acid value...

Embodiment 3

[0040] This embodiment is used to illustrate the method for reducing the acid value of petroleum provided by the present invention.

[0041] Such as figure 1 As shown, the desalted and dehydrated crude oil with an acid value of 13.10 mg KOH / g enters the preheater 2 from pipeline 1 and preheats to 405 ° C for thermal deacidification reaction. The time of thermal deacidification reaction is 50 seconds, and the obtained heat The deacidification reaction product is cooled to 200°C in pipeline 3 through heat exchange with 30°C atmospheric residue, and then sent to esterification reactor 4 together with 1.0% by weight of triethylene glycol relative to the weight of desalted and dehydrated crude oil. Esterification and deacidification reaction, the reaction time is 280 minutes, the obtained esterification and deacidification product enters the fractionation tower 6 from the pipeline 5 for fractionation, and obtains the deacidified crude oil product and small molecule gas with an acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com