Thermal transfer ink, thermal transfer sheet and method of thermal transfer recording therewith

A technology of thermal transfer printing and ink, which is applied in the direction of copying/marking methods, inks, chemical instruments and methods, etc. It can solve the problems of large molecular light absorption coefficient and no safety problems, and achieve good light fastness and good light fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

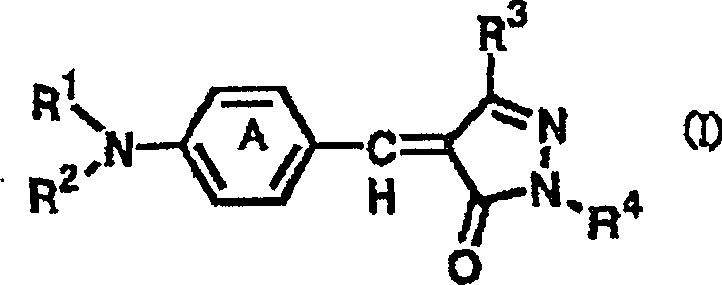

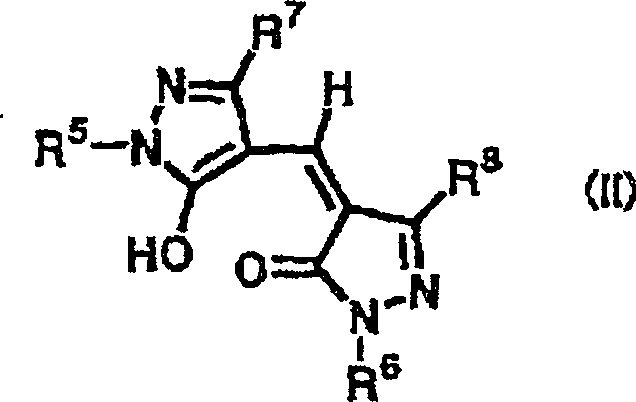

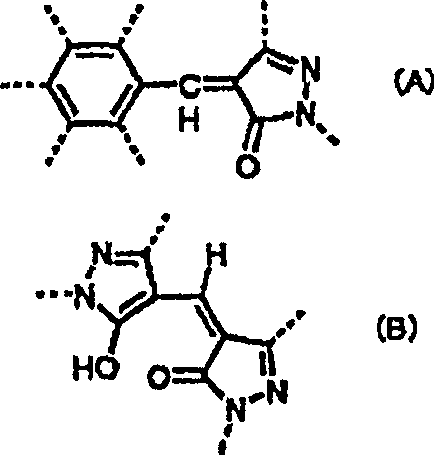

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] The mixture of the following composition was treated with an ultrasonic cleaner for 30 minutes to prepare ink (Y) and ink (C).

[0099] [Composition of ink (Y) (parts by weight)]

[0100] No.1-1 dye: 3.0

[0101] No.2-1 dye: 3.0

[0102] Phenoxy resin ("PKHJ", produced by Union Carbide Corporation): 10

[0103] Tetrahydrofuran: 90

[0104] [Composition of ink (C) (parts by weight)]

[0105] Cyan dye (structure (III)): 8.0

[0106] Phenoxy resin ("PKHJ", produced by Union Carbide Corporation): 10

[0107] Tetrahydrofuran: 90

[0108]

[0109] Use a wire-wound coater to apply the obtained ink (Y) and ink (C) to a polyethylene terephthalate film (6μm thick), and dry (about 1μm dry film thickness) to form a color料层。 The material layer. 10 parts by weight of acrylic resin (trade name: BR-80, produced by Mitsubishi Rayon Co., Ltd.) and 1 part by weight of amino-modified silicone oil (trade name: KF393, produced by Shin-Etsu Chemical Co., Ltd.) And 89 parts by weight of toluene ...

Embodiment 2~3

[0116] The preparation of ink, preparation of thermal transfer sheet, transfer recording, and light resistance test were performed in the same manner as in Example 1, except that the dye shown in Table 3 was used as the yellow dye. The results are shown in Table 4.

Embodiment 4

[0141] The ink prepared by the following method was used instead of the ink used in Example 1, and the preparation, transfer recording, and evaluation of the transfer sheet were performed in the same manner as in Example 1, thereby obtaining a recording with uniform color density. It was also confirmed that the recorded matter thus obtained had good light resistance.

[0142] [Ink composition (parts by weight)]

[0143] No.1-1 dye: 3.0

[0144] No.2-1 dye: 3.0

[0145] AS resin (product name: Denka AS-S, produced by Denka Chemical Industry Co., Ltd.): 10

[0146] Toluene: 70

[0147] Cyclohexanone: 10

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com