Method for removing haloacetic acids in the drinking water

A haloacetic acid and drinking water technology, applied in the field of water treatment, achieves the effects of high removal rate, short treatment time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The iron shavings used in the present invention reduce and remove haloacetic acid, and control Fe in the effluent 2+ The concentration method is as follows: (the sample is a 100 μg / L haloacetic acid solution prepared with tap water):

[0027] Step 1: Degrease the iron shavings formed in the process of 45# steel processing, first use cleaning solution to degrease, such as washing powder, soak for 10-30min, and then soak in 2-3wt% dilute sulfuric acid for 0.5-1.5h to remove rust. Wash and set aside;

[0028] The second step: use plexiglass column, the diameter of the glass column is 29mm, the height is 500mm, the bottom is equipped with a support layer of glass beads with a height of 30mm, the particle size of the glass beads is 3-5mm, and then filled with manganese sand and manganese sand The height is 50mm.

[0029] Step 3: Crush the pretreated iron shavings to a length of about 20-50mm, put them on the upper layer of manganese sand filter material, and fill them unti...

Embodiment 2

[0034] With reference to Example 1, the 50mm manganese sand loaded in the third step is replaced with manganese sand and granular activated carbon, and the manganese sand and granular activated carbon are filled with 25mm respectively, and other materials and steps are unchanged.

[0035] The total content of haloacetic acid in the effluent of Example 2 is less than 5 μg / L, the total iron is less than 0.3 mg / L, and the chroma is less than 15 degrees. While the haloacetic acid in the water is well removed, other conventional indicators basically meet the requirements of national drinking water. specification.

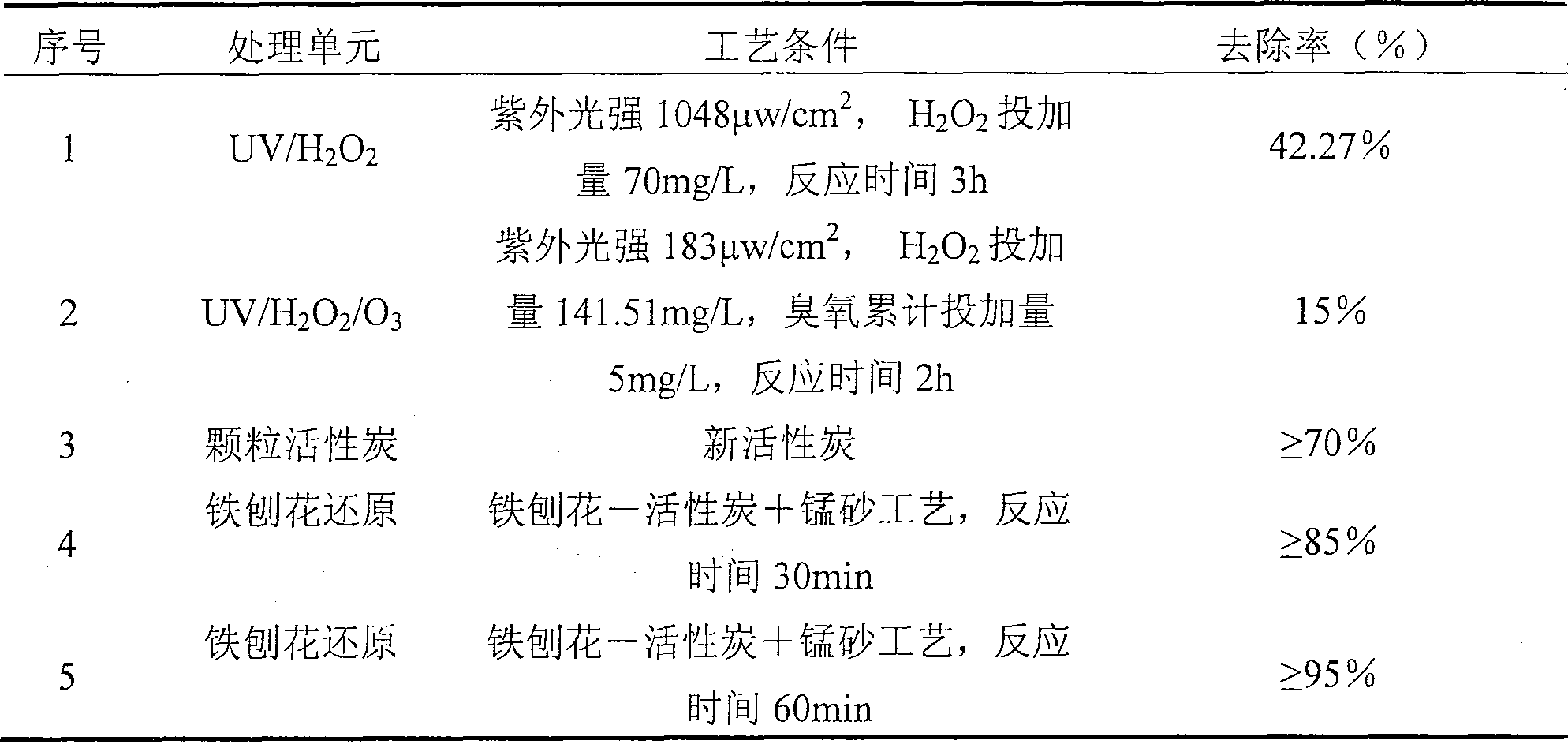

[0036] Using iron shavings to reduce and remove TCA in water, compared with the advanced oxidation process: the preparation of water contains 100 μg / L of TCA, respectively, using UV / H 2 o 2 , UV / H 2 o 2 / O 3 Compared with the reduction treatment of iron shavings and granular activated carbon adsorption unit, the test method of trichloroacetic acid is according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com