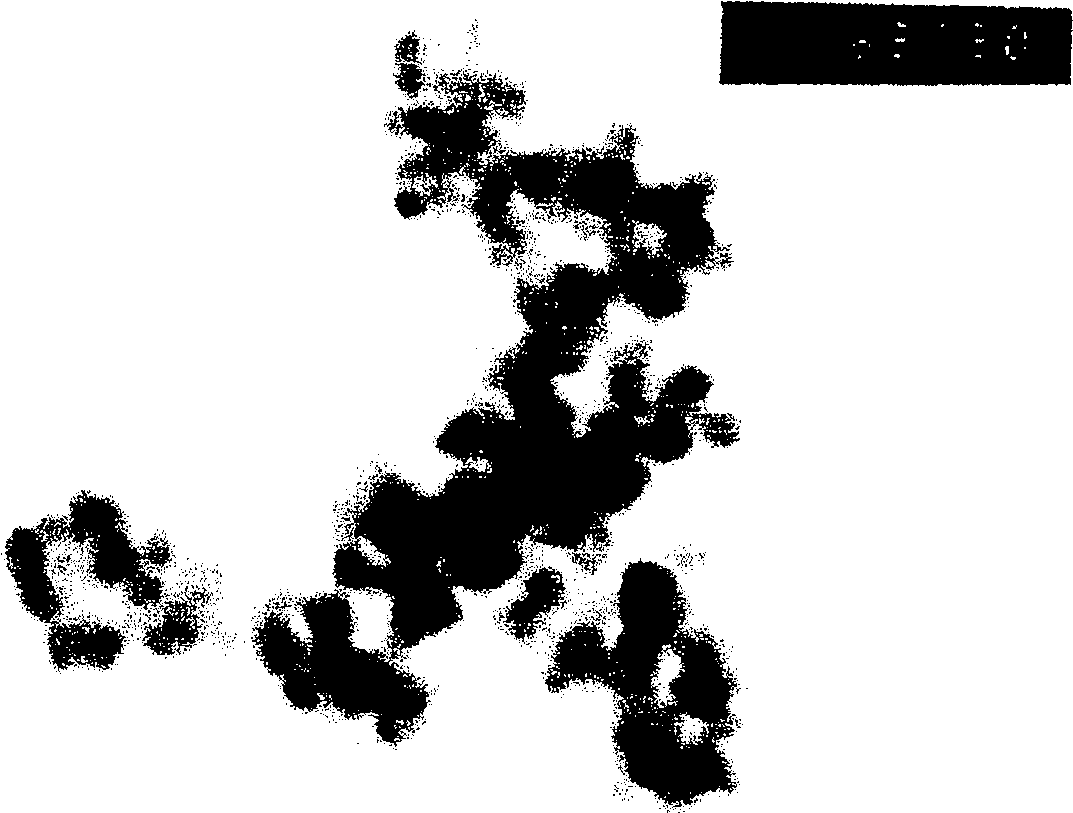

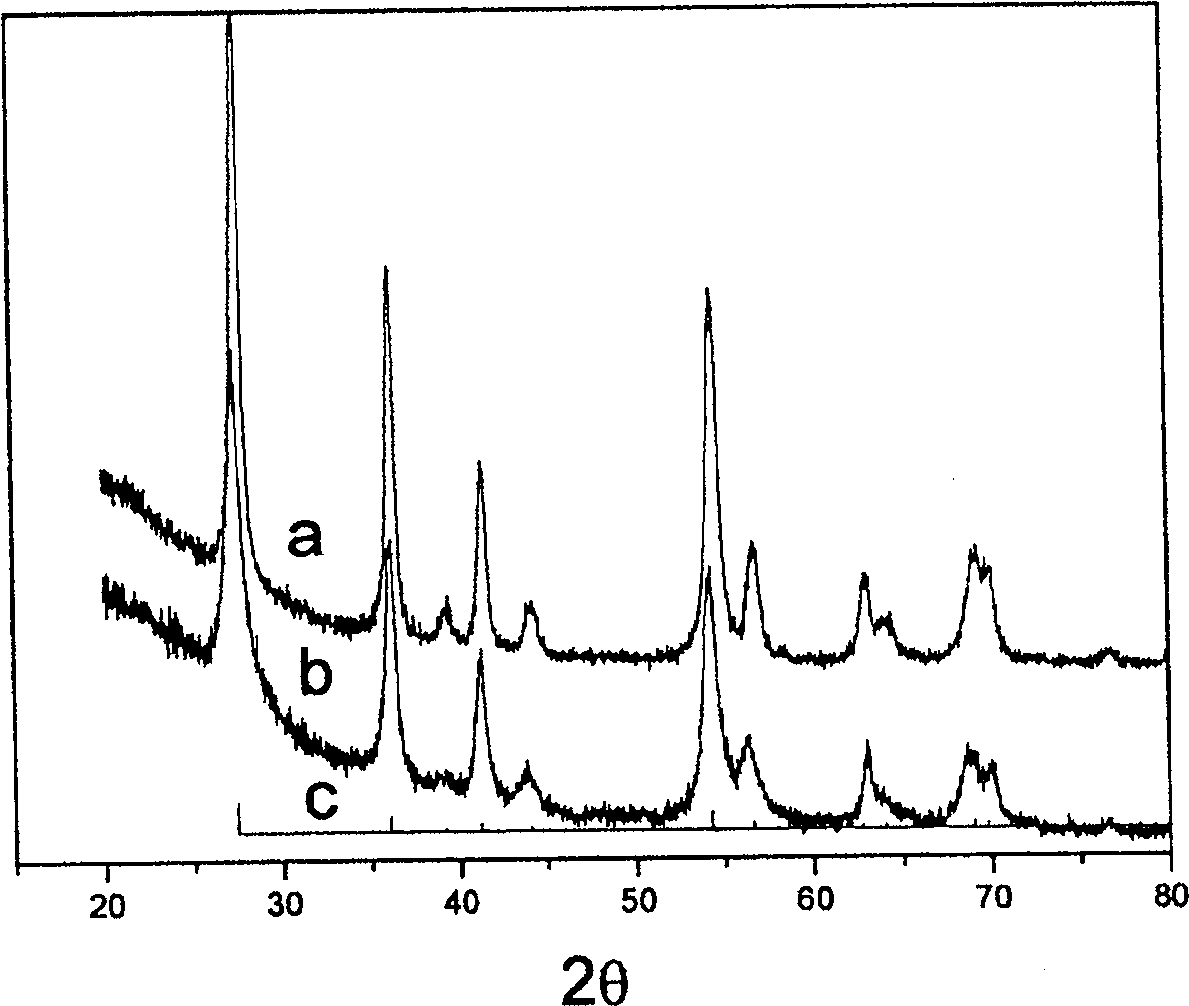

Preparation method of red schorl type titanium oxide nano powder

A titanium dioxide and nano-powder technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of irregular shape of titanium dioxide nano-powder particles, complicated production process, low powder yield, etc. The effect of mass preparation, simple method and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

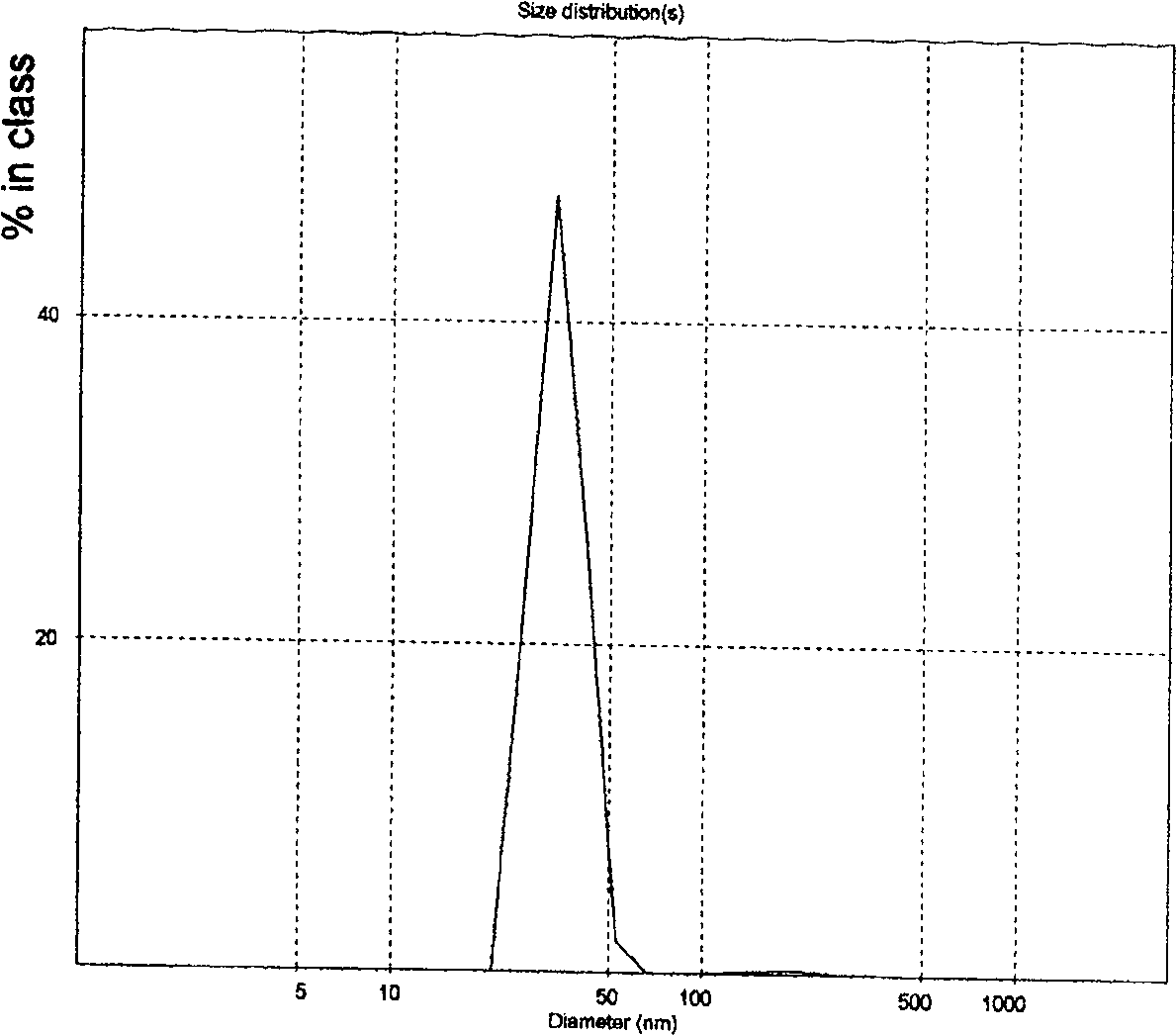

[0012] Example 1: The preparation was completed according to the following steps: a) First, add titanium tetrachloride to the stirring deionized water at 0°C to obtain a titanium tetrachloride solution with a molar concentration of 0.1M, and then heat it at 40°C. Stir for 2.5 hours to obtain a titanium tetrachloride glue solution. After that, the titanium tetrachloride glue solution is aged for 1 day and then filtered to obtain a titanium tetrachloride glue solution with a PH value of 1, and then the titanium tetrachloride glue solution is ultrasonically dispersed, and a stabilizer is added to obtain a titanium dioxide sol; The ultrasonic frequency of the ultrasonic dispersion of the titanium tetrachloride glue solution is 10KHz, the addition amount of the stabilizer is 10% by weight of the titanium tetrachloride glue solution, and the stabilizer is ethanol. b) First dilute the titanium dioxide sol and deionized water at a volume ratio of 1:1, and configure the titanium tetrachlor...

Embodiment 2

[0013] Example 2: The preparation is completed according to the following steps: a) First, add titanium tetrachloride to the stirring deionized water at 2°C to obtain a titanium tetrachloride solution with a molar concentration of 0.2M, and then heat it at 55°C Stir for 2.3 hours to obtain a titanium tetrachloride glue solution. After that, the titanium tetrachloride glue solution was aged for 2 days and then filtered to obtain a titanium tetrachloride glue solution with a pH of 1.5, and then the titanium tetrachloride glue solution was ultrasonically dispersed, and a stabilizer was added to obtain a titanium dioxide sol; The ultrasonic frequency of the ultrasonic dispersion of the titanium tetrachloride glue solution is 25KHz, the addition amount of the stabilizer is 8% by weight of the titanium tetrachloride glue solution, and the stabilizer is ethanol. b) First dilute the titanium dioxide sol and deionized water in a volume ratio of 1:2, and prepare the titanium tetrachloride a...

Embodiment 3

[0014] Example 3: The preparation was completed according to the following steps: a) First, add titanium tetrachloride to the stirring deionized water at 5°C to obtain a titanium tetrachloride solution with a molar concentration of 0.3M, and then heat it at 70°C. Stir for 2 hours to obtain a titanium tetrachloride glue solution. After that, the titanium tetrachloride glue solution was aged for 3 days and then filtered to obtain a titanium tetrachloride glue solution with a pH of 2, and then the titanium tetrachloride glue solution was ultrasonically dispersed, and a stabilizer was added to obtain a titanium dioxide sol; The ultrasonic frequency of the ultrasonic dispersion of the titanium tetrachloride glue solution is 35KHz, the addition amount of the stabilizer is 6% (weight) of the titanium tetrachloride glue solution, and the stabilizer is ethanol. b) First dilute the titanium dioxide sol and deionized water in a volume ratio of 1:3, and prepare the titanium tetrachloride aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com