Raster and light valve array processed by electric microcomputer for laser filmsetting and its production

A technology of grating light valve and processing method, which is applied in the direction of diffraction grating, optical mechanical equipment, phototypesetting device, etc., can solve the problems of low scanning precision and slow scanning speed of laser phototypesetting system, and achieve high imaging precision, reduced volume, The effect of increasing the scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

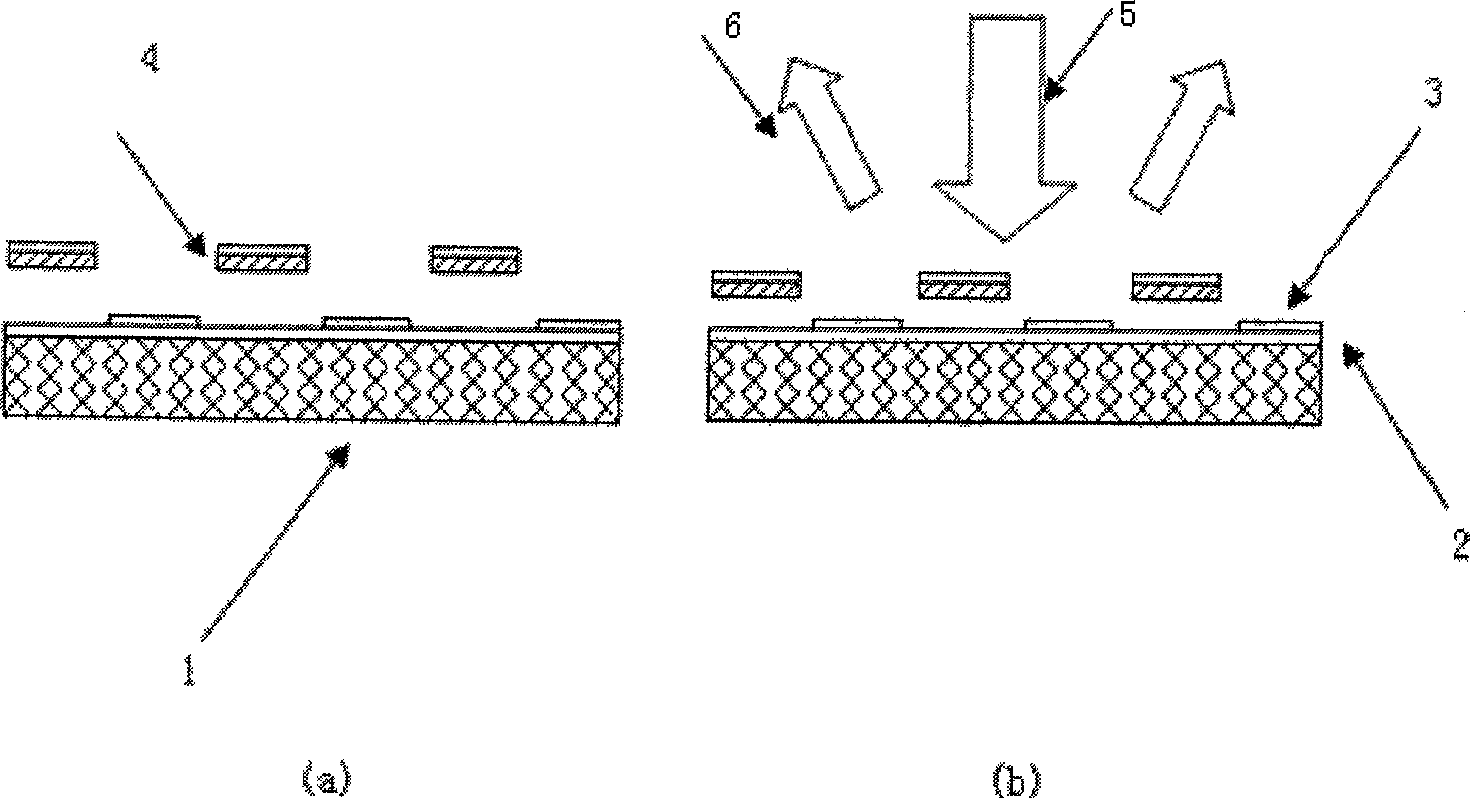

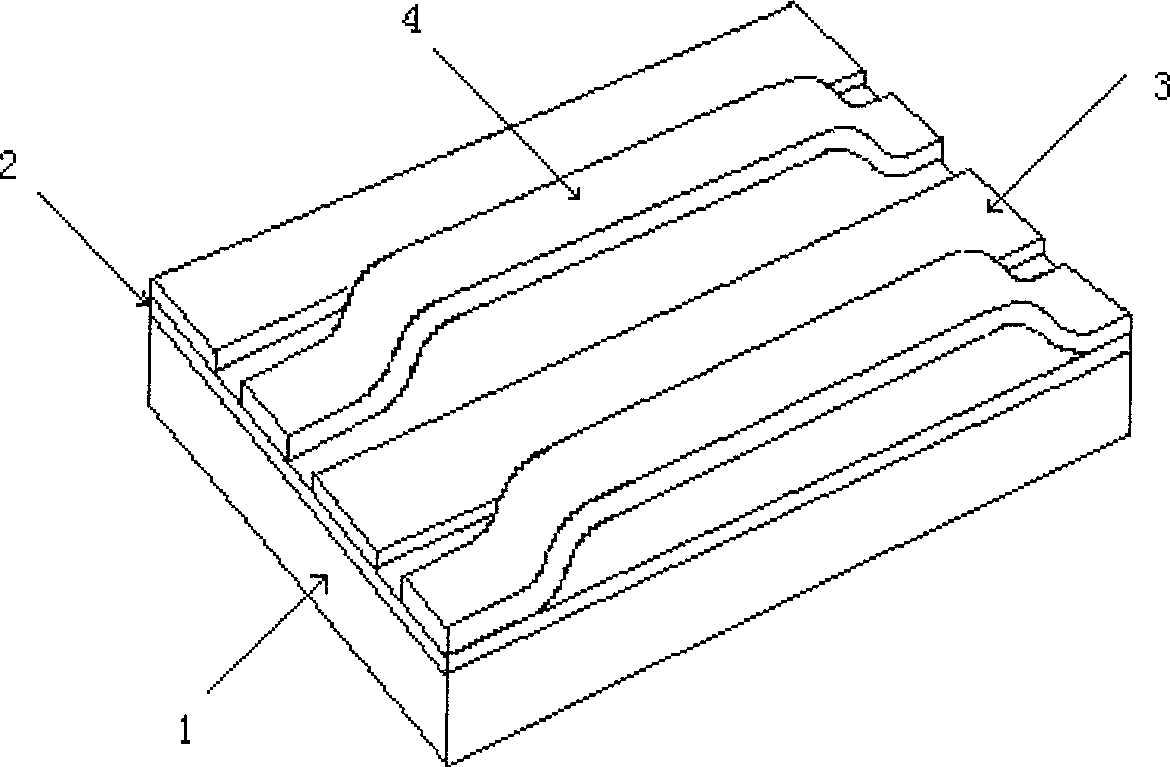

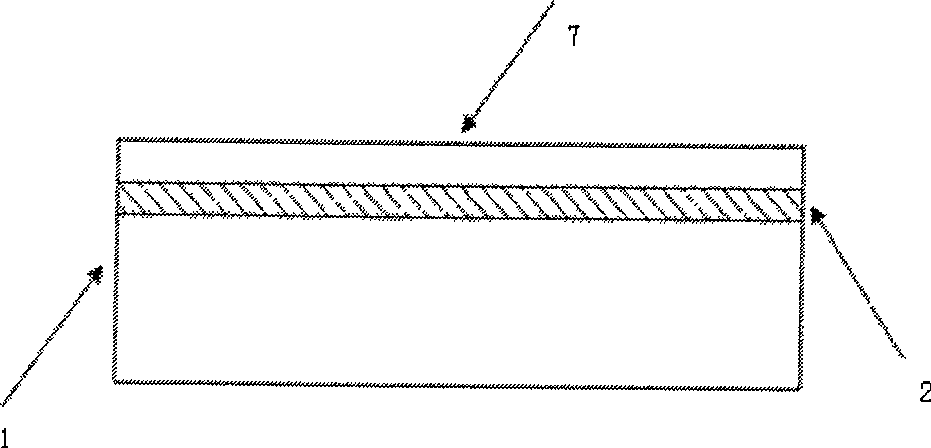

[0066] 1) Growing a silicon dioxide layer and a silicon sacrificial layer on the silicon substrate, growing a layer of silicon nitride, single crystal silicon or polycrystalline silicon on the surface of the silicon sacrificial layer, the thickness of the silicon substrate is 300 microns, and the thickness of the silicon dioxide layer is 0.7 Micron, the thickness of the silicon sacrificial layer is 1 micron, and the thickness of silicon nitride, monocrystalline silicon or polycrystalline silicon is 170 nanometers;

[0067] 2) Spray a layer of photoresist on the surface of silicon nitride, single crystal silicon or polycrystalline silicon with a uniform machine, and place the mask plate with the pattern engraved on the photoresist layer under the exposure machine for exposure treatment ;

[0068] 3) After the exposure treatment, a developing operation is carried out in a dark room to remove the photoresist on the exposed part, and the remaining photoresist is used as a protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com