Spacing mechanical arm perpendicular style modularized joint

A technology of modular joints and space manipulators, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of small output torque per unit mass, large joint volume, and large power consumption, and achieve high overall rigidity, reliable transmission, and power consumption. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

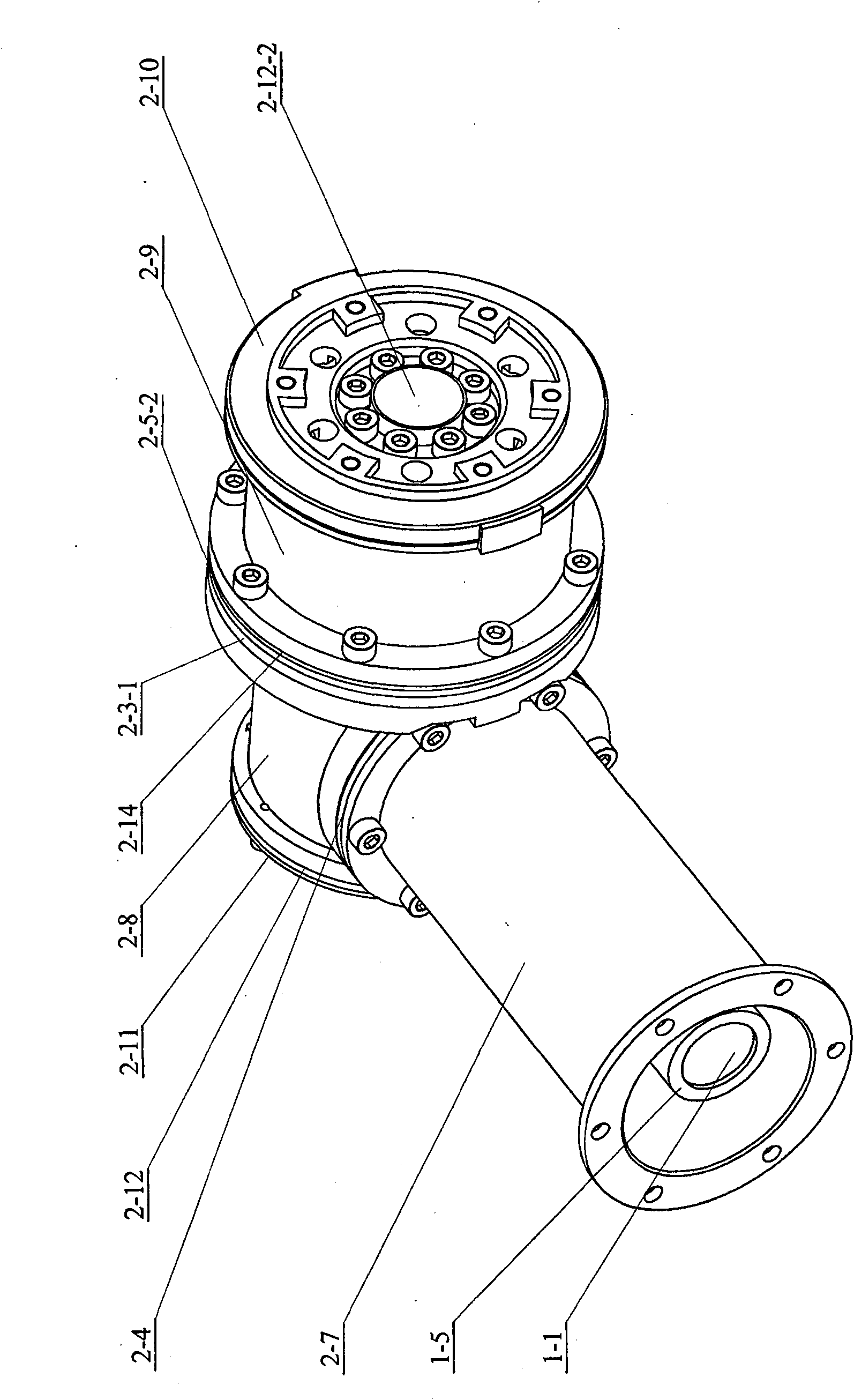

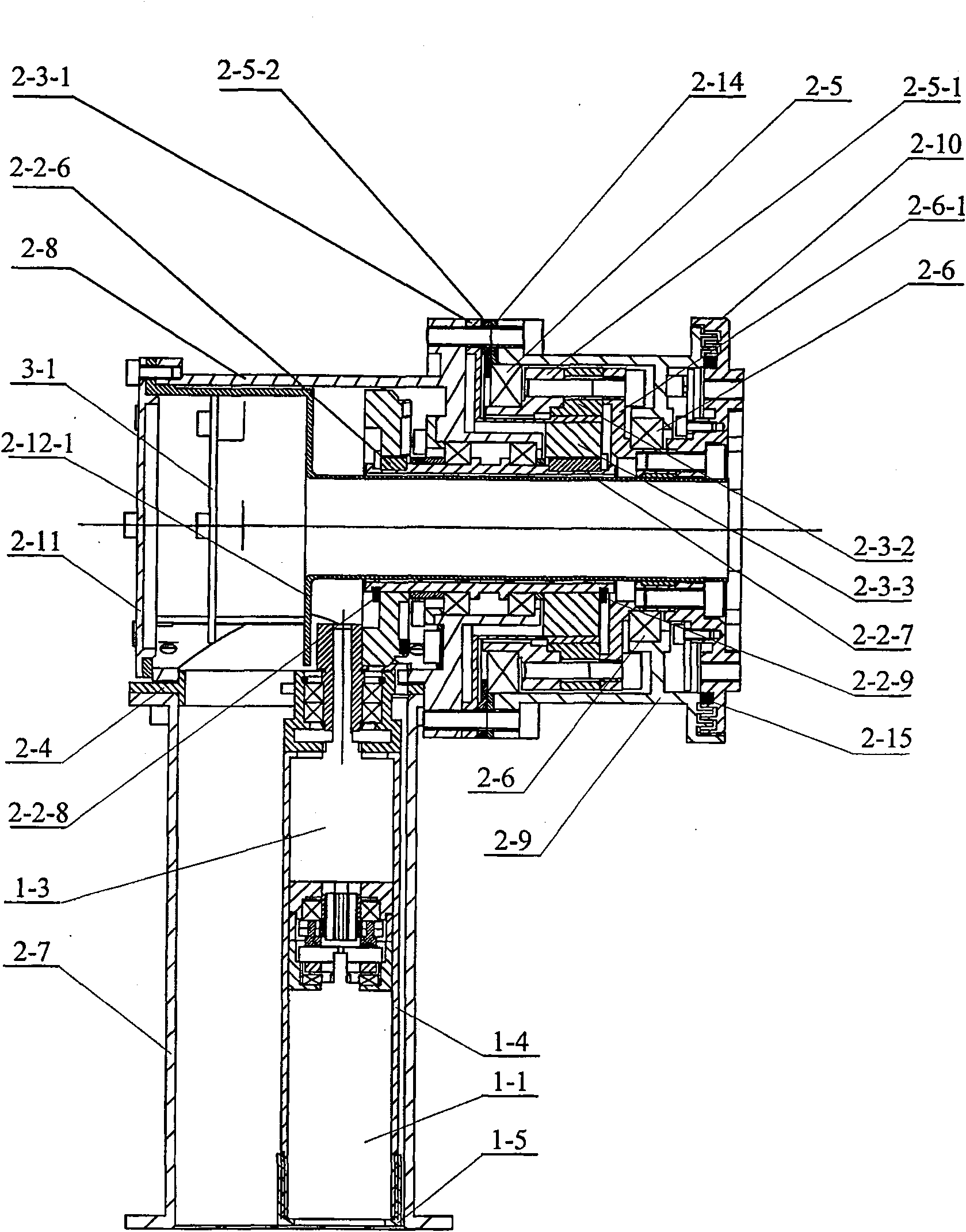

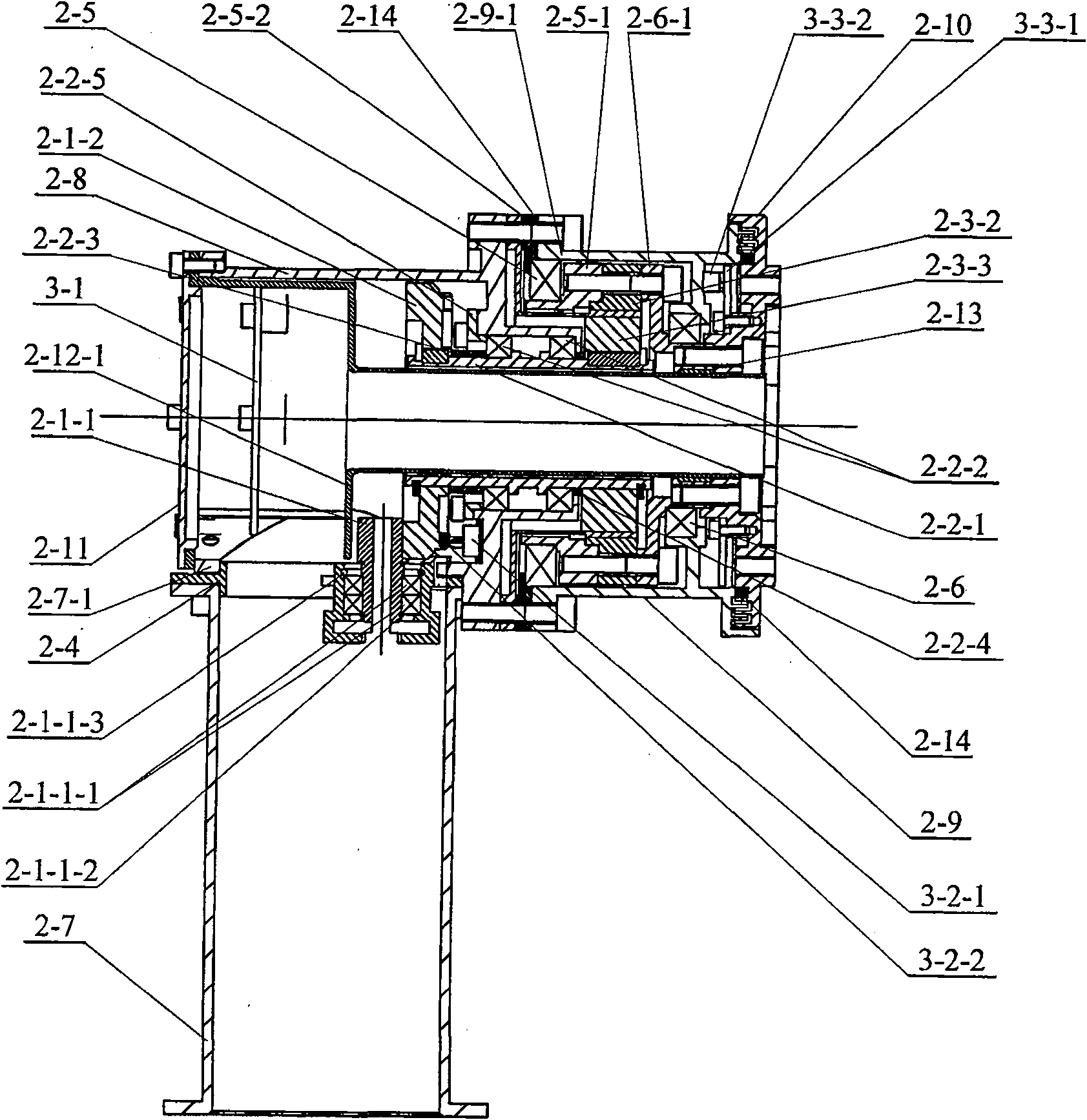

[0006] Specific implementation mode one: (see Figure 1 to Figure 11) This embodiment is composed of a drive device, a joint mechanism and an electrical part. The drive device is composed of a DC brushless motor 1-1, a friction reverse brake, a planetary reducer 1-3, a motor sleeve 1-4 and a motor The sleeve cover 1-5 is composed of, and the joint mechanism is composed of an eccentric motor sleeve fixing plate 2-4, a crown gear device, a hollow transmission shaft device, a harmonic reducer, a thin-walled bearing 2-5, and a thin-walled bearing Two 2-6, thin-walled bearing one inner ring support seat 2-5-1, thin-walled bearing one outer ring retaining ring 2-5-2, thin-walled bearing two inner ring support seat 2-6-1, the first shell 2-7, second shell 2-8, third shell 2-9, output flange 2-10, joint rear end cover 2-11, sleeve 2-12, isolation support ring 2-13, adjusting gasket 2-14 and felt 2-15, the electrical part is composed of Hall switch, position sensor and transfer circui...

specific Embodiment approach 2

[0008] Specific embodiment two: the motor sleeve 1-4 described in this embodiment, the motor sleeve cover 1-5, the hollow drive shaft 2-2-1, the sleeve one 2-2-3, the sleeve two 2-2 -4, hollow bearing cover 2-2-5, key one 2-2-6, key two 2-2-7, eccentric motor sleeve fixing plate 2-4, thin-walled bearing one inner ring support seat 2-5 -1. Thin-walled bearing first outer ring retaining ring 2-5-2, thin-walled bearing second inner ring support seat 2-6-1, first shell 2-7, second shell 2-8, third shell 2- 9. The output flange 2-10, the joint rear end cover 2-11 and the sleeve 2-12 are all made of titanium alloy material. Since the material of the bearing is 440C (stainless steel) and the difference in thermal expansion coefficient between titanium alloy (TC4) is very small, the bearing will not be stuck due to the large difference in thermal expansion coefficient between the inner ring seat of the bearing and the outer ring seat of the bearing and the inner and outer steel rings ...

specific Embodiment approach 3

[0009] Specific embodiment three: In order to ensure reliable braking during reverse transmission in this embodiment, the friction plate one 1-2-5, the friction plate two 1-2-6 and the inner wall of the shell three 1-2-12 The coefficient of friction is greater than Where r is the radius of the pitch circle of the output gear shaft 1-2-7, R is the inner diameter of the housing 3 1-2-12, and b is the width of the opening groove on the friction plate. The friction reverse brake consumes no power when braking. There is an appropriate interference fit between the cavities formed by the three bearings 1-2-3 and the output shaft of the motor, so that the three bearings 1-2-3 can squeeze the output of the brushless DC motor 1-1 axis. A clearance fit should be selected between the three pin shafts 1-2-2 and the inner rings of the three bearings 1-2-3. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com