Internal tricyclic decelerator

A technology of reducer and ring plate, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of poor reliability of crank structure, unbalanced additional torque, and low life of ring plate bearing, etc., to achieve product application The effect of widening the surface, reducing the span, and improving the torque output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

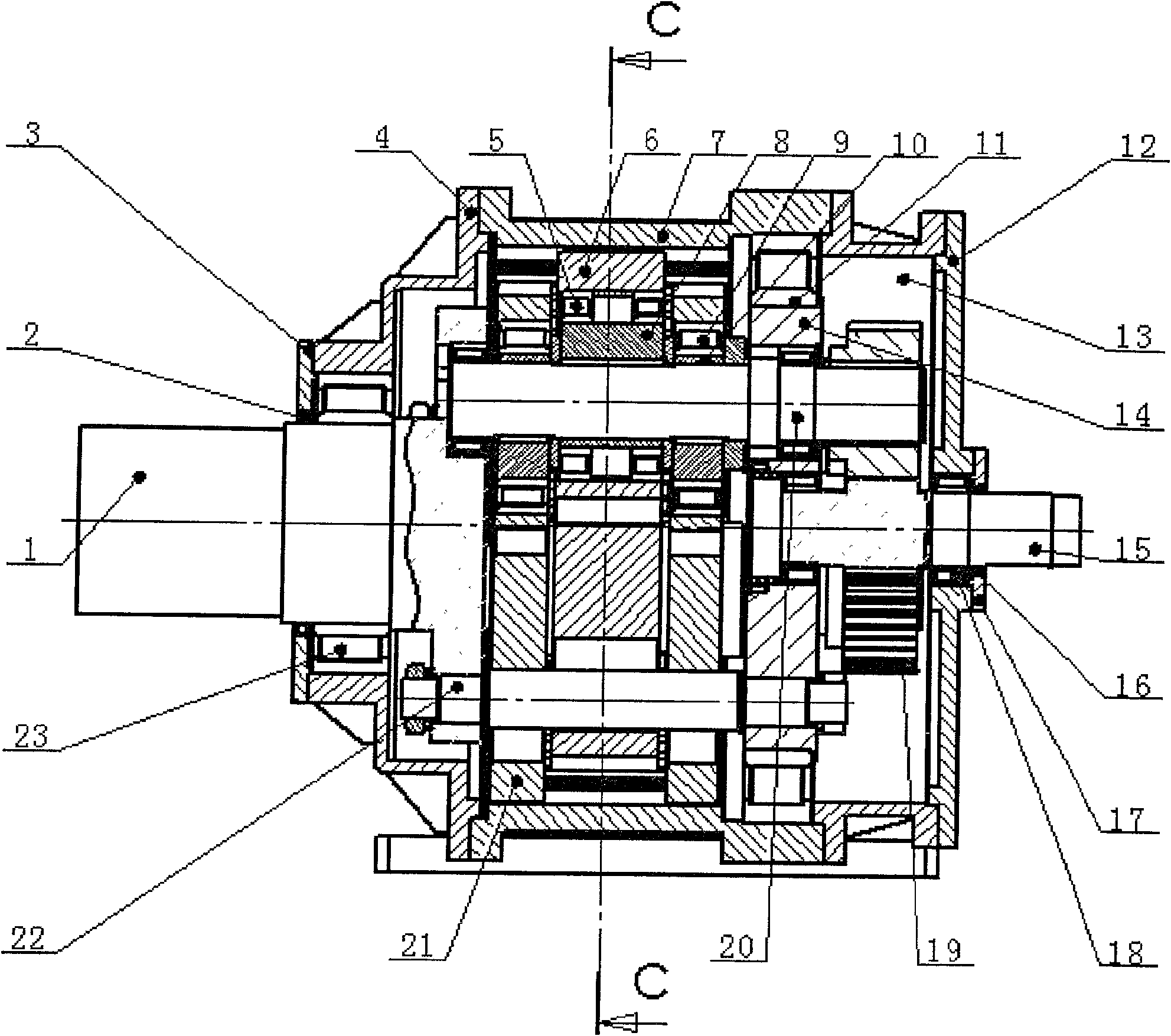

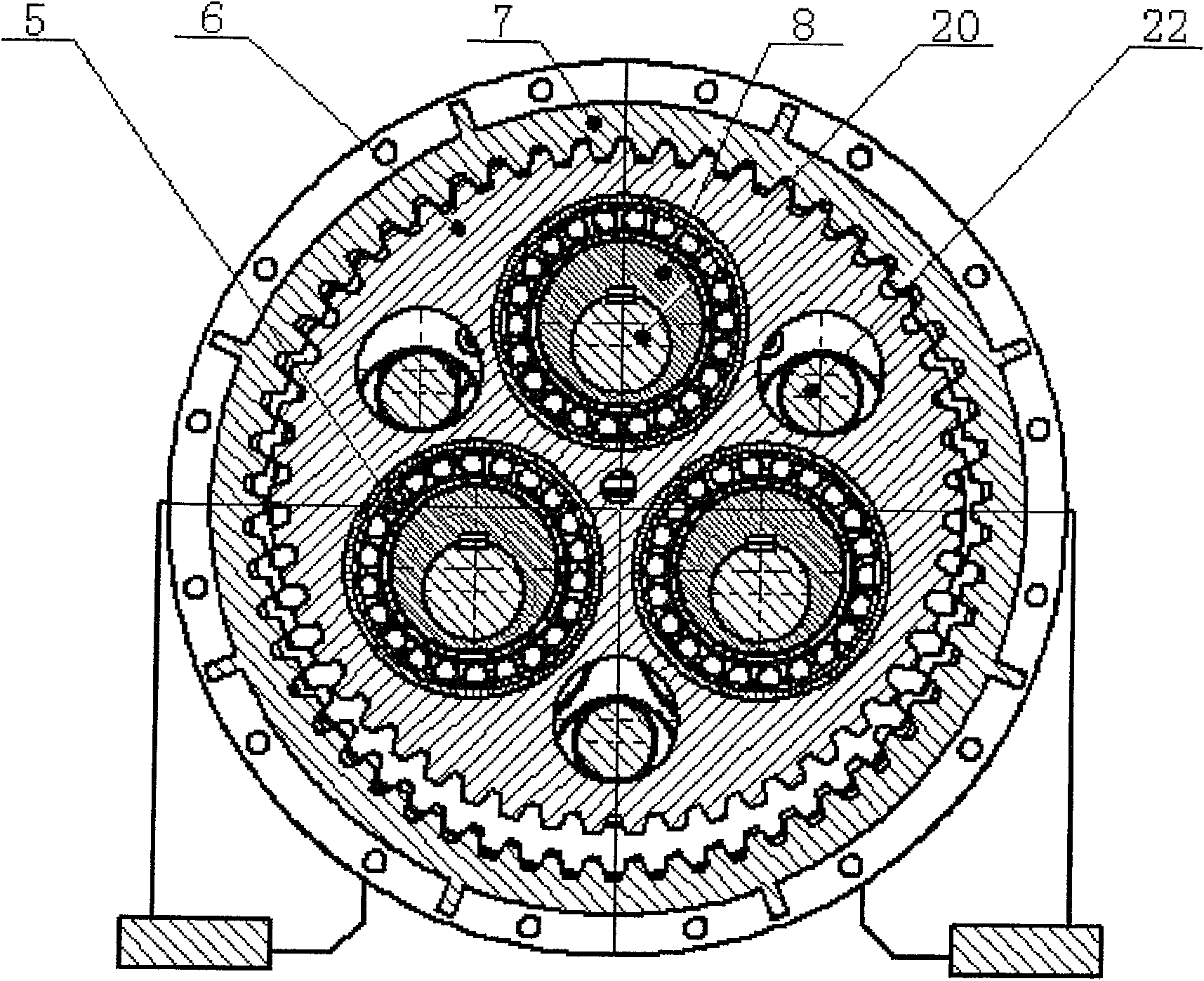

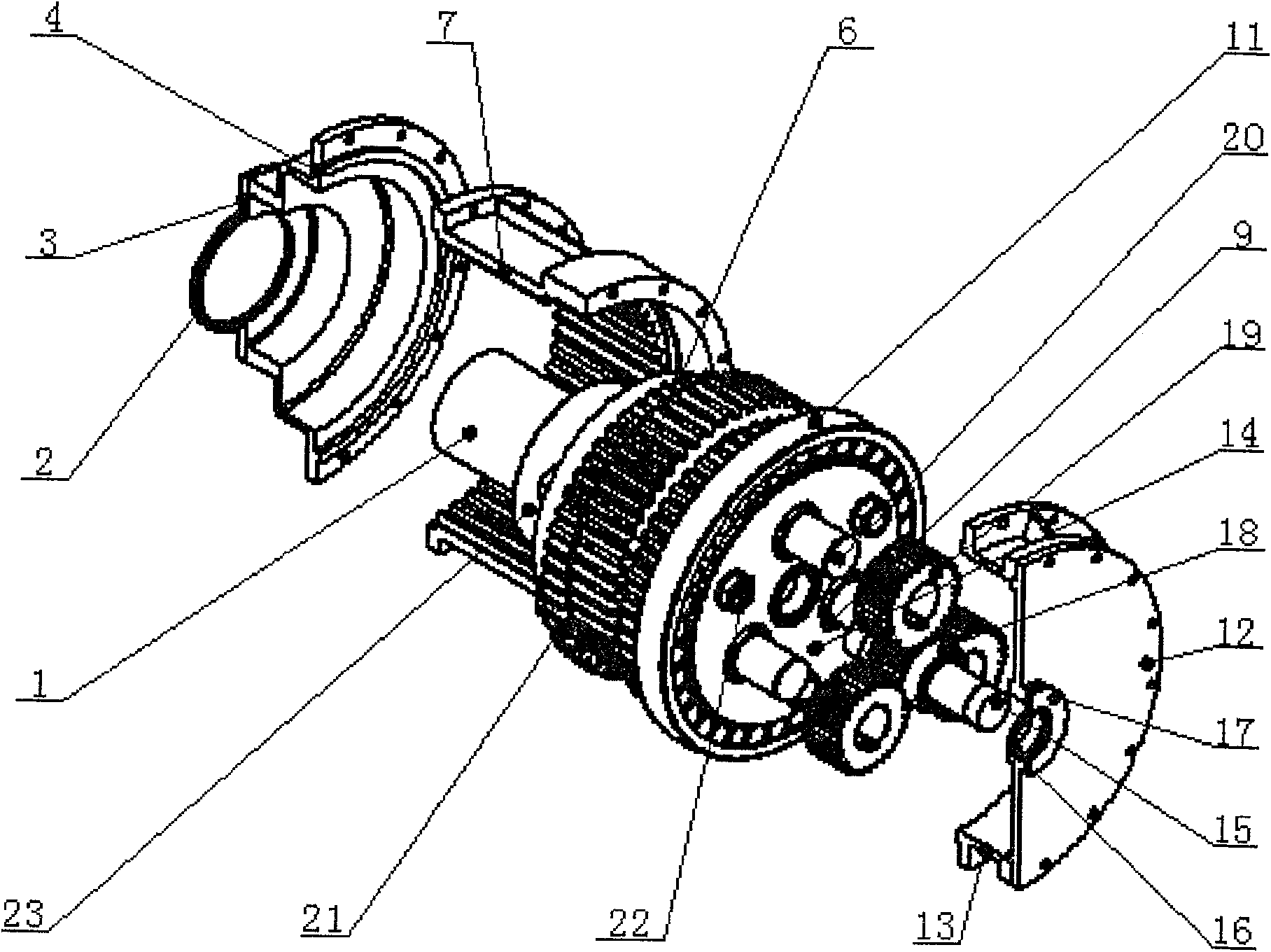

[0025] see figure 1 , figure 2 and image 3 , the present invention consists of an input gear shaft 15, a bearing frame 14, three synchronous planetary wheels 19, three three-key shafts 20, three connecting support rods 22, two side gear ring plates 21, a middle gear ring plate 6, a The internal ring gear 7, an output shaft 1, and an eccentric sleeve 8, a side eccentric sleeve 10, a sealing ring 2, an output shaft end cover pressure plate 3, and an end cover 4 are composed.

[0026] One end of the output shaft 1 is equipped with a bearing 23 , the outer side of the bearing 23 is provided with an end cover 4 , the output shaft end cover pressing plate 3 is installed on the outside of the end cover 4 , and the sealing ring 2 is housed in the output shaft end cover pressing plate 3 . One end of input gear shaft 15 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com