Phosphate water, oil-repellent containing fluoroolefin and its preparation method and uses

A water- and oil-repellent and oil-repellent technology is applied in the fields of phosphate-based fluorine-containing water- and oil-repellent agents and fluorine-containing surfactants, and can solve the problem of high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

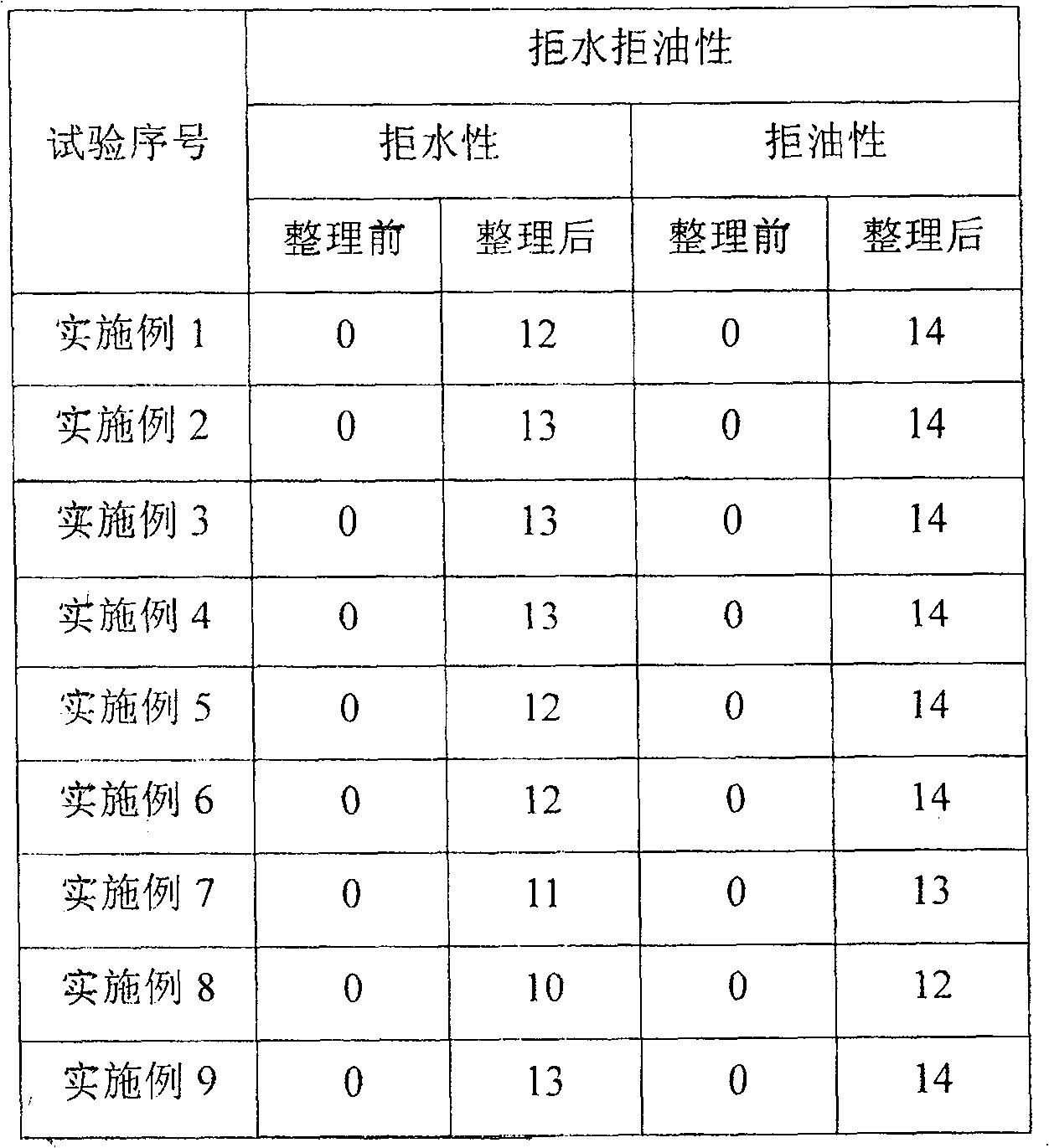

Examples

Embodiment 1

[0039] Add 75.24 grams of ethylene glycol and 122.28 grams of triethylamine to a 500-ml 4-neck glass flask equipped with a stirrer, a constant pressure funnel, a condensing reflux tube, and a thermometer, and the temperature rises to 40 degrees. Start to drip 300.5 grams of perfluorohexene C 6 F 12 , the dropwise addition was completed within 1 hour, and the product was washed with water to neutrality after 4 hours of reaction to obtain about 321.58 grams of C 6 F 11 OCH 2 CH 2 oh.

[0040] Add 72.9 grams of dipolyphosphoric acid to the 4-neck glass flask of 500 milliliters equipped with stirrer, constant pressure funnel, condensation reflux tube, and thermometer, then dropwise add the reaction product of one step, and react for 6 hours at 80 degrees. A pale yellow viscous liquid was obtained, followed by addition of 10 mL of water for hydrolysis at this temperature for 2 hours. Then, the temperature was lowered to room temperature, 20 mL of an equivalent amount of dieth...

Embodiment 2

[0044] Add 75.24 grams of ethylene glycol and 122.28 grams of triethylamine to a 500-ml 4-neck glass flask equipped with a stirrer, a constant pressure funnel, a condensing reflux tube, and a thermometer, and the temperature rises to 40 degrees, and 450.0 grams of perfluorononene C 9 F 18 , the dropwise addition was completed within 1 hour, and the product was washed with water to neutrality after 4 hours of reaction to obtain about 470.1 g of C 9 F 18 OCH 2 CH 2 oh.

[0045] Add 72.9 grams of dipolyphosphoric acid to the 4-neck glass flask of 500 milliliters equipped with stirrer, constant pressure funnel, condensation reflux tube, and thermometer, then dropwise add the reaction product of one step, and react for 6 hours at 80 degrees. A pale yellow viscous liquid was obtained, followed by addition of 10 mL of water for hydrolysis at this temperature for 2 hours. Then, the temperature was lowered to room temperature, 20 mL of an equal amount of sodium carbonate aqueous ...

Embodiment 3

[0049] Use hydroquinone instead of ethylene glycol, other same as Example 1, obtain perfluorononene phenoxyphosphoric acid diethanolamine salt emulsion, adopt the method of adding inside to process paper, then dry at 120 degrees, the application results are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com