Integrated processing technique for retting-hemp waste water and equipment thereof

A treatment process and integrated technology, which is applied in the process of wastewater treatment, reduced water/sewage treatment, water/sewage multi-stage treatment, etc. problems, to achieve the effect of improving biodegradability, improving biodegradability, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

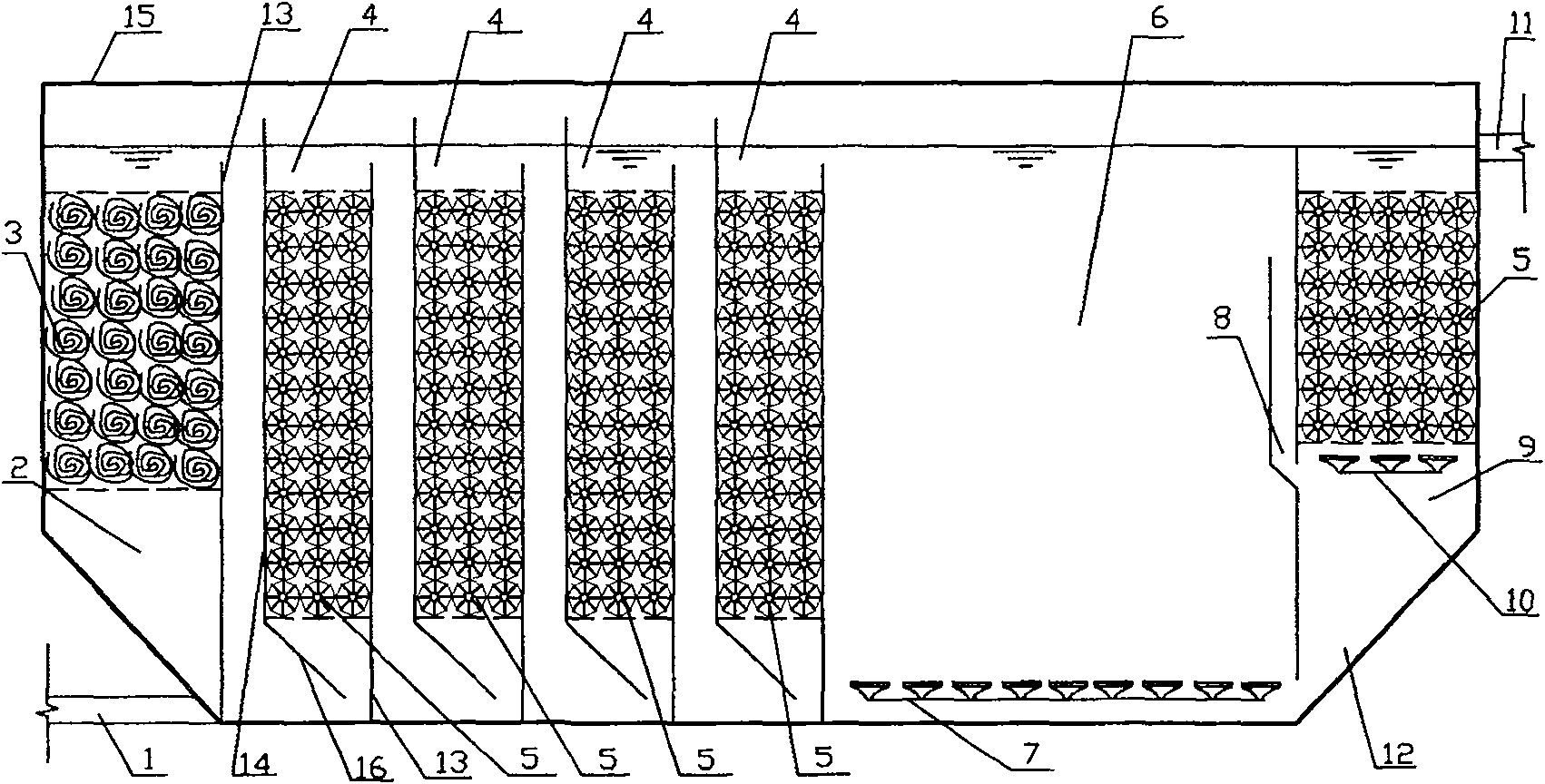

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

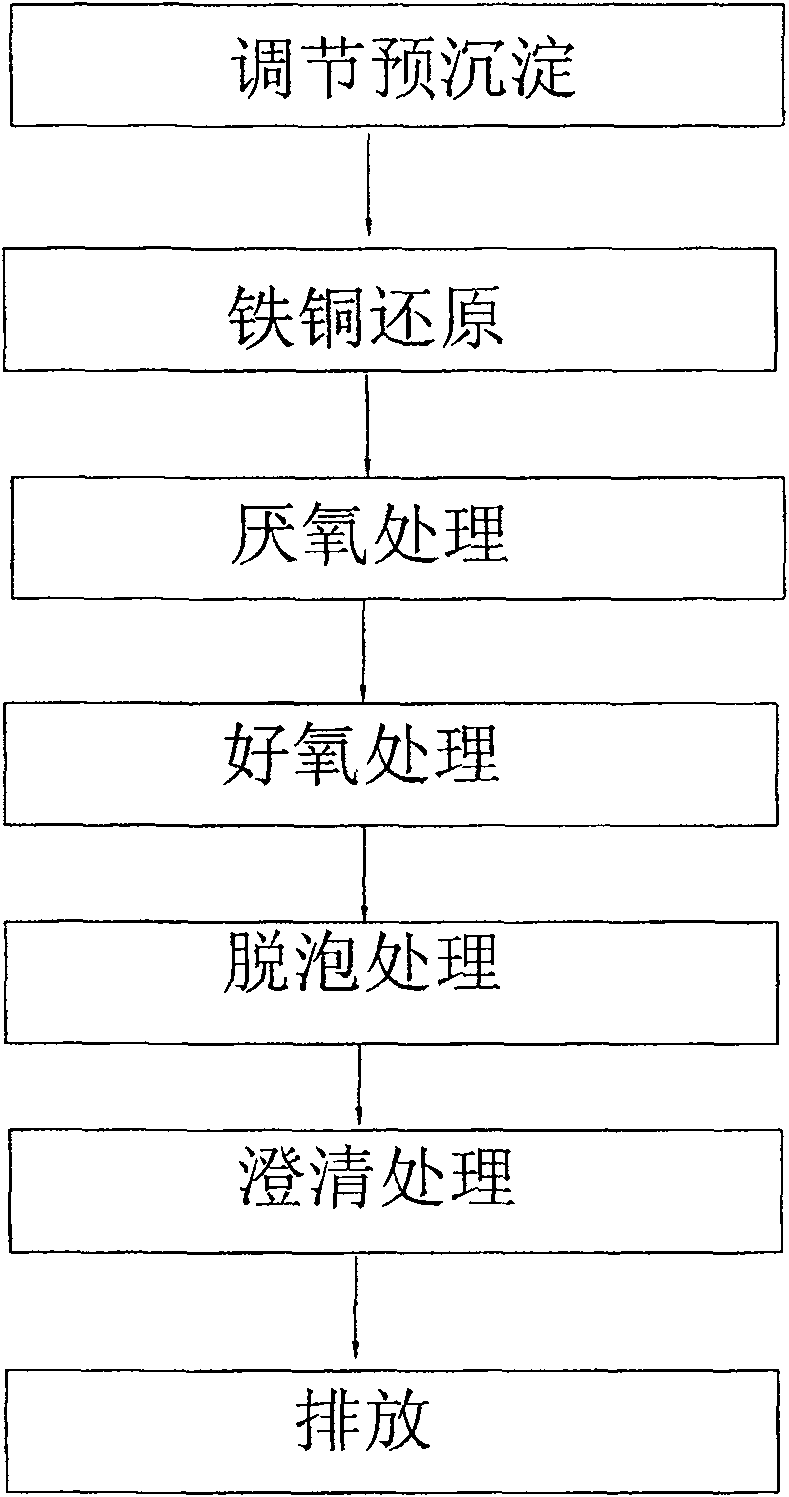

[0028] figure 2 Shown, a kind of integrated treatment process of hemp degumming waste water, comprises regulating pre-precipitation step, also comprises the following steps after above-mentioned regulation pre-precipitation step:

[0029] Iron-copper reduction step: After adjusting the pre-precipitation step, the hemp degumming wastewater enters the iron-copper reduction bed. The weight ratio of iron and copper in the iron-copper reduction bed is 5:1. Through electrocatalysis, the iron and copper in the iron-copper reduction bed Decompose the above-mentioned refractory substances in the hemp degumming wastewater through the adjustment pre-precipitation step;

[0030] Anaerobic treatment steps: the hemp degumming wastewater treated by iron-copper reduction first passes through the downflow channel of the baffled anaerobic filter bed, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com