Method for removing residual minim chloroform from tea polyphenol

A technology for tea polyphenols and chloroform, which is applied in the chemical industry, can solve the problems of frequent regeneration, limited adsorption capacity, complex facilities, etc., and achieves the effects of good effect, low energy consumption and processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention will be further described:

[0029] 1. Determination of adsorption capacity of different adsorbents and tea polyphenol solutions containing different concentrations of chloroform

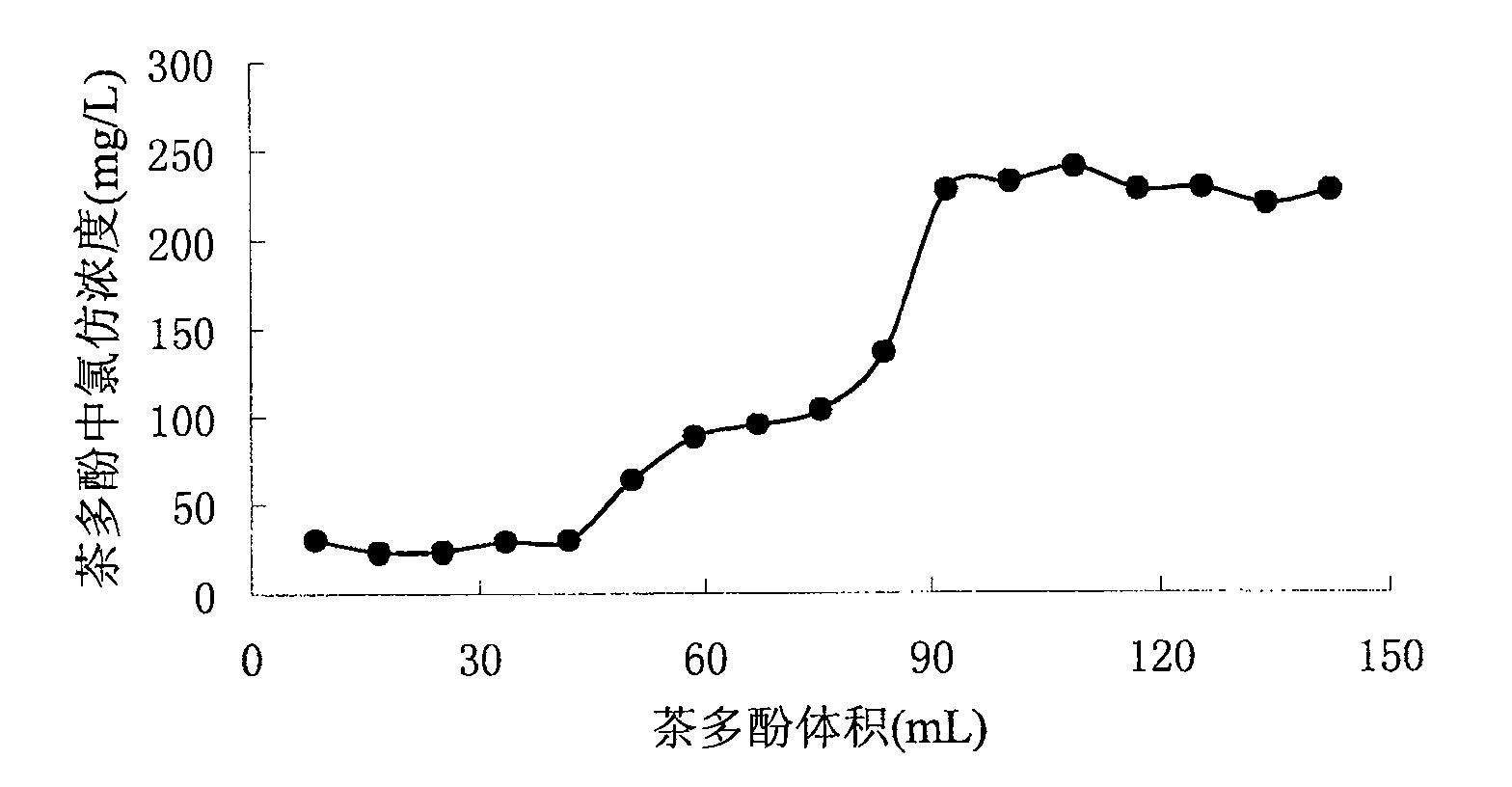

[0030] The hydrophobic adsorbent is activated in the air at 550°C for two hours and then added to the adsorption column after cooling. The adsorption column has a height of 45cm, an inner diameter of 1.5cm, and a loading capacity of 185g of zeolite adsorbent. Solution flow rate to be treated: 3.0 mL / min.

[0031]The flow rate was adjusted to be stable, and the tea polyphenol solution containing chloroform was input to the adsorption column with a constant flow pump. Use a volumetric flask to take a sample at the outlet of the column every 6 minutes. After 36 minutes, take a sample every 3 minutes until 105 minutes before stopping the delivery of the solution. The sample obtained in the first 36 minutes was extracted by adding 18ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com