Burning device capable of saving fuel and reducing pollution

A combustion device and fuel technology, applied in the direction of non-flammable liquid/gas transportation, combustion method, control combustion, etc., can solve the problems of bulky combustion equipment, serious pollution of ambient air, waste of fuel and energy, etc., and achieve good application effect. Improve the ecological environment and increase the effect of unit content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

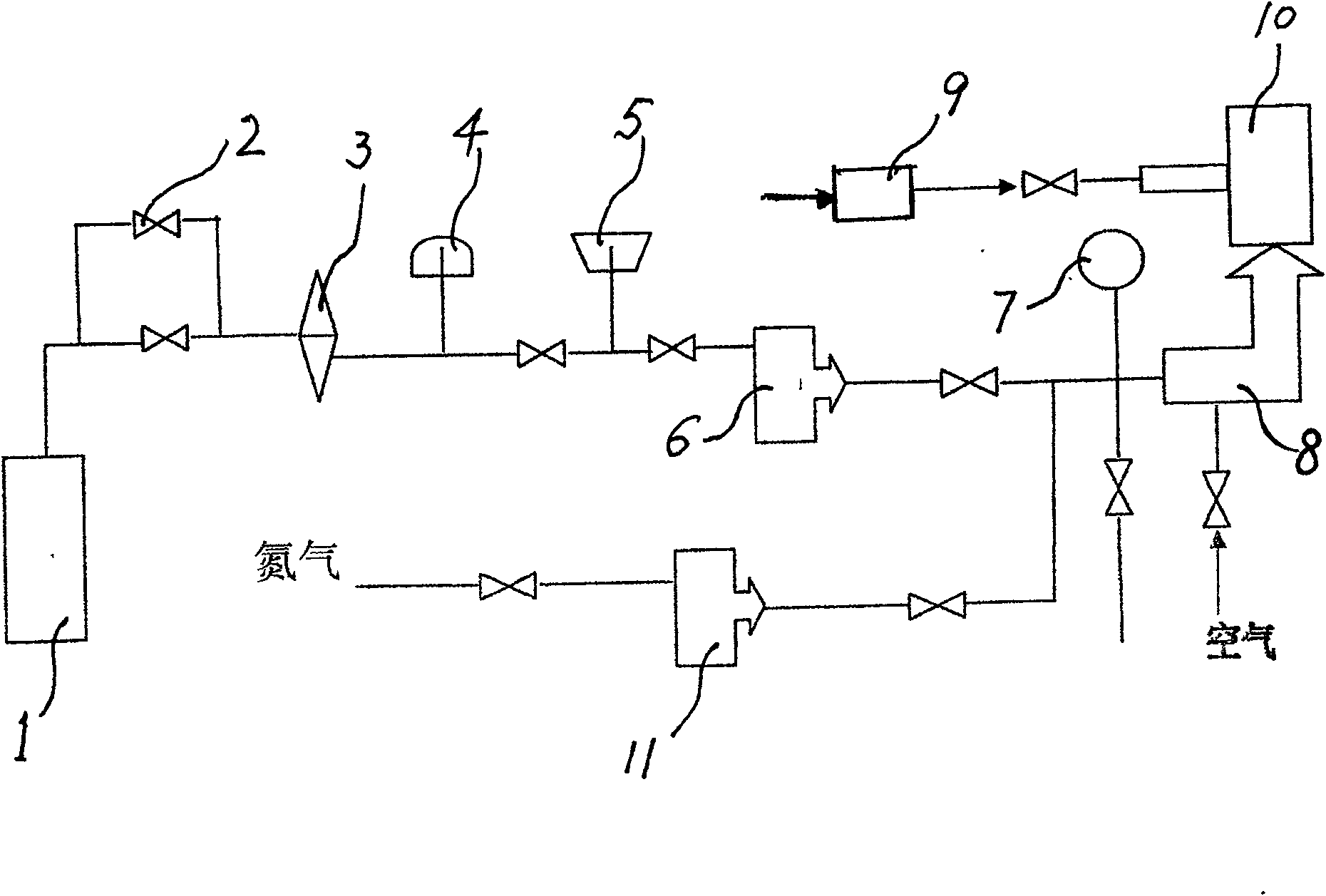

[0010] Referring to the accompanying drawings, the scheme of the present invention can be implemented according to actual needs through a set of automatic control system. Buffer 8 and other parts. The output end of the combustion-supporting gas manufacturing device 1 communicates with the input end of the combustion-supporting gas homogeneous mixer 6 to form a combustion-supporting gas conveyor. A professional gas flow control valve 2, a flow meter 3, a high-temperature quick shut-off valve 4 and a pressure gauge 5 are provided on the gas pipeline between the combustion-supporting gas manufacturing device 1 and the combustion-supporting gas homogeneous mixer 6, and the combustion-supporting gas homogeneous mixer 6 A combustion-supporting gas concentration measurement meter 7 is provided on the gas pipeline between the combustion-supporting gas-air mixing buffer 8 . When the combustion device is working, the combustion-supporting gas is produced by the combustion-supporting ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com