Superfine microtea powder preparation process

A preparation process, ultra-fine technology, applied in the field of ultra-fine tea powder preparation process, can solve the problems of low utilization rate of tea active ingredients, poor taste and nutritional effect, waste with slag, etc., to maintain natural green and nutrition, mellow taste and Refreshing, the effect of increasing the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The ultra-fine tea powder preparation process comprises the following steps:

[0025] a. Select fresh green tea leaves as raw materials, kill enzymes, sterilize, and sort; then dry the surface moisture by air at minus 20 degrees; then dry to make the water content as low as 2.5%; then use high-speed air The tube is cooled and crushed into flakes, impurities are removed, stems are removed, and then put into an electric ultrafine pulverizer to pulverize to obtain tea powder;

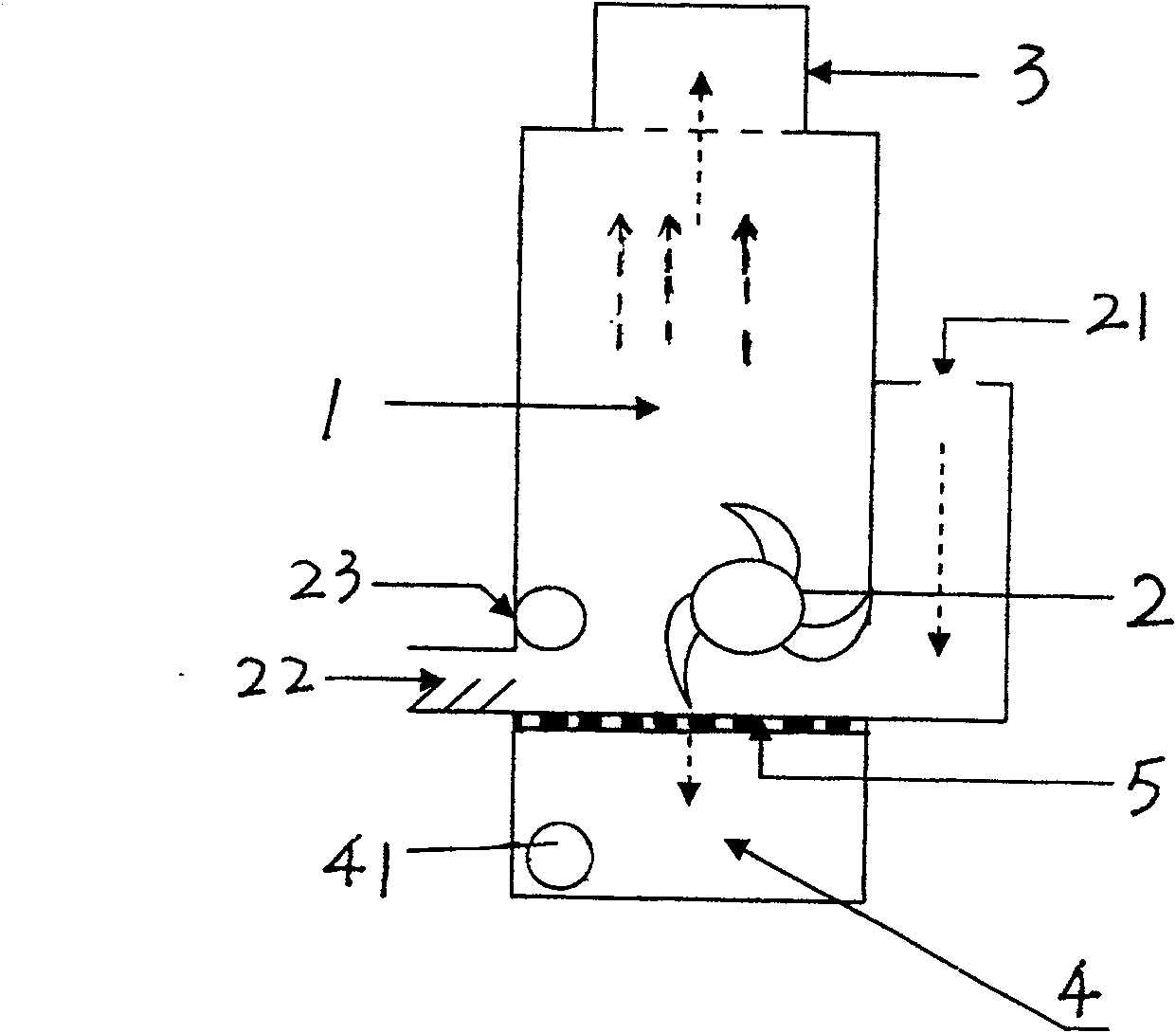

[0026] B, the tea powder grain that step 1 obtains is sent into the bottom of collection chamber 1 through the entrance 21 of collection chamber, as figure 1 Shown, and make the stirring blade 2 rotation that is positioned at collection chamber bottom, the rotating speed of stirring blade 2 is 4000 rev / s, and the diameter of stirring blade is 18 centimetres, and the rotation of stirring blade stirs the tea powder grain in the collection chamber, makes tea The powder particles are flying up (as show...

Embodiment 2

[0030] The ultra-fine tea powder preparation process comprises the following steps:

[0031] a. Select fresh green tea leaves as raw materials, kill enzymes, sterilize, and sort; then dry the surface moisture by air at minus 15 degrees; then dry to make the water content as low as 3.0%; then use high-speed air The tube is cooled and crushed into flakes, impurities are removed, stems are removed, and then put into an electric ultrafine pulverizer to pulverize to obtain tea powder;

[0032] b. Send the tea powder obtained in step 1 into the lower part of the collection chamber, and rotate the agitating blade located at the lower part of the collection chamber. The rotating speed of the agitating blade is 5000 rpm, and the diameter of the agitating blade is 20 cm for use to agitate the tea powder At the same time, air is blown into the bottom of the collection chamber, and the air blown in is filtered by a filter; at the upper part of the collection chamber, 3.5 meters above the ...

Embodiment 3

[0034] The ultra-fine tea powder preparation process comprises the following steps:

[0035] a. Select fresh tea leaves as raw materials, kill enzymes, sterilize, and sort; then dry the surface moisture by air at minus 15 degrees; then dry to make the water content as low as 2.5%; then use high-speed air duct Cool and break into flakes, remove impurities, pick stems, and then put it into an electric ultrafine pulverizer to pulverize to obtain tea powder;

[0036] b. Send the tea powder obtained in step 1 into the lower part of the collection chamber, and rotate the agitating blade located at the lower part of the collection chamber. The rotating speed of the agitating blade is 3000 rpm, and the diameter of the agitating blade is 15 cm for use to agitate the tea powder At the same time, air is blown into the bottom of the collection chamber, and the air blown in is filtered by a filter; at the upper part of the collection chamber, 1.5 meters above the central axis of the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com