Method for linked production of potassium fluoride and white carbon black

A technology of white carbon black and potassium fluoride, applied in the field of co-production of potassium fluoride and white carbon black, can solve the problems of high cost, achieve good economic value and social value, reduce production cost, and solve pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

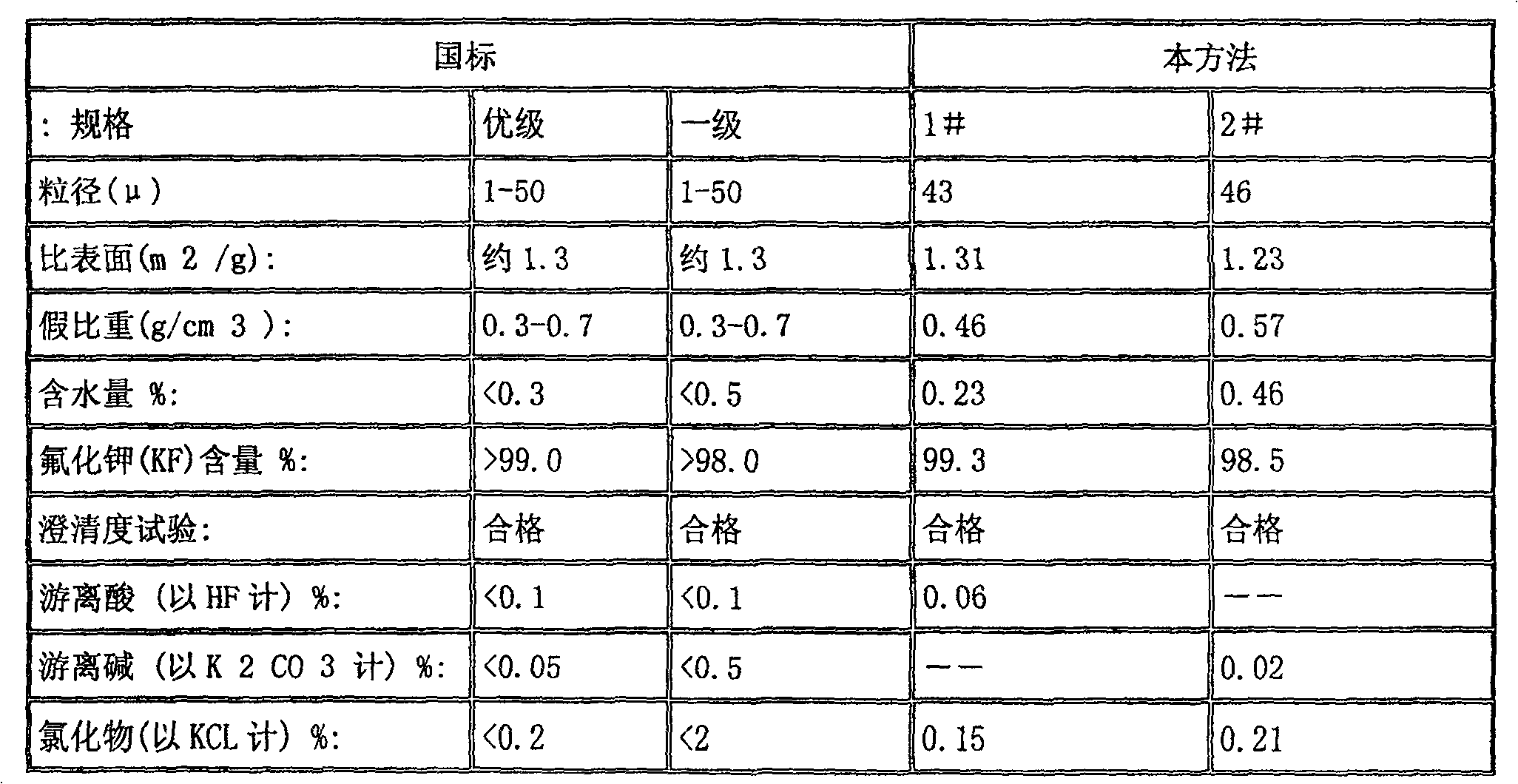

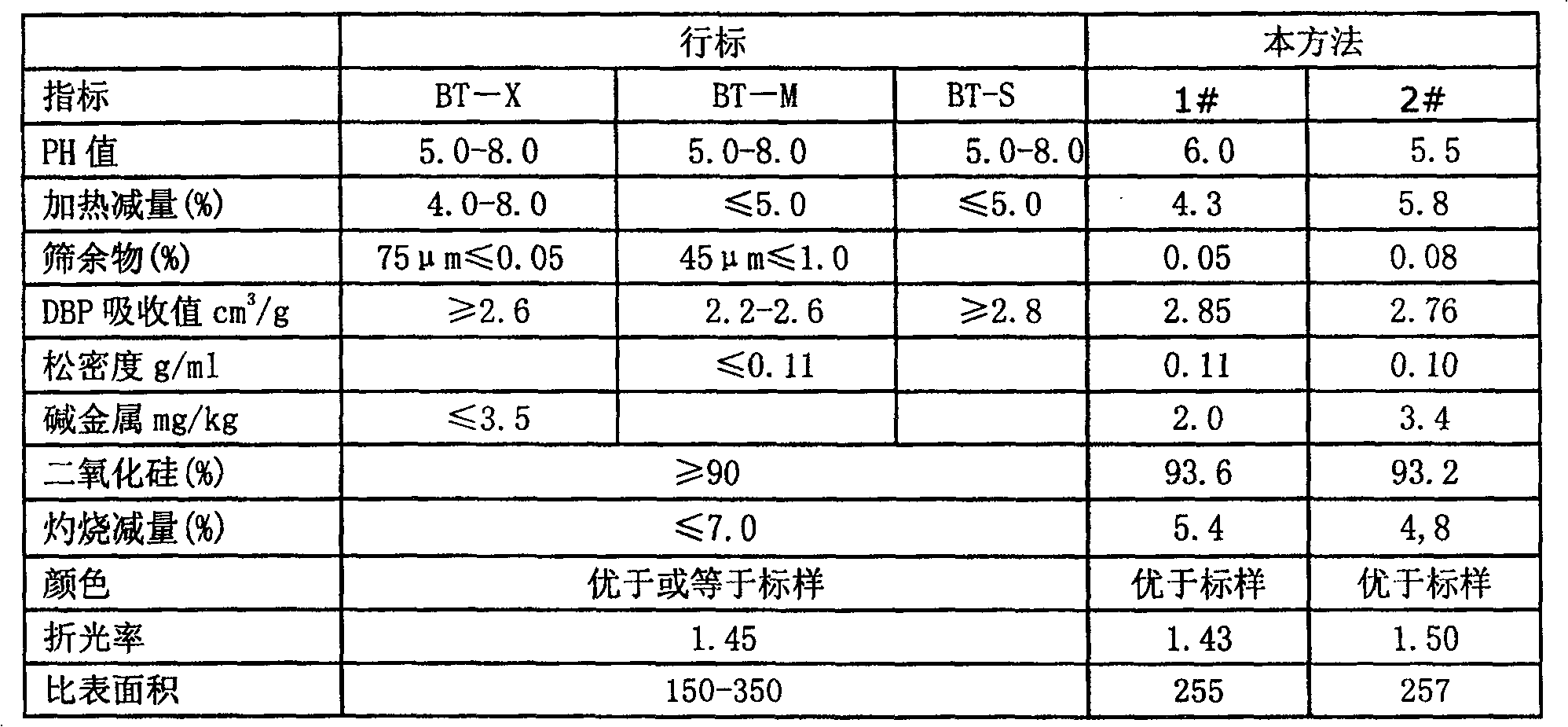

[0018] The method for producing potassium fluoride and co-producing white carbon black in this embodiment is as follows: the concentration of fluosilicic acid is configured to be 10%, and potassium hydroxide and fluosilicic acid or potassium fluosilicate are reacted to obtain white carbon black, The reaction temperature is 85°C, the pH value of the reaction end point is 9.0, and a slurry of silica precipitation and potassium fluoride solution is obtained; the silica slurry is filtered and washed to obtain a silica ointment and a potassium fluoride solution. The black ointment is washed and dried to obtain a white carbon black product; the potassium fluoride solution is concentrated and spray-dried to obtain a potassium fluoride product.

Embodiment 2

[0020] The method for producing potassium fluoride and co-producing white carbon black in this embodiment is as follows: the concentration of fluosilicic acid is configured to be 20%, and potassium hydroxide and fluosilicic acid or potassium fluosilicate are reacted to obtain white carbon black, The reaction temperature is 90°C, the pH value of the reaction end point is 9.5, and the slurry of silica precipitation and potassium fluoride solution is obtained; the silica slurry is filtered and washed to obtain silica ointment and potassium fluoride solution. The black ointment is washed and dried to obtain a white carbon black product; the potassium fluoride solution is concentrated and spray-dried to obtain a potassium fluoride product.

Embodiment 3

[0022] The method for producing potassium fluoride co-producing white carbon black in this embodiment is as follows: the concentration of fluosilicic acid is configured to be 30%, potassium hydroxide and fluosilicic acid or potassium fluosilicate are reacted to obtain white carbon black, and the reaction The temperature was 95° C., the pH value of the reaction end point was 10.0, and the slurry of silica precipitation and potassium fluoride solution was obtained. The silica slurry is filtered and washed to obtain silica ointment and potassium fluoride solution. The silica ointment is washed and dried to obtain a silica product; the potassium fluoride solution is concentrated and spray-dried to obtain potassium fluoride. product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com