Catalyst for preparing ethylamine compounds, preparation method and application thereof

A molybdenum phosphide catalyst and compound technology, which is applied in the field of catalysts for the preparation of ethylamine compounds, can solve the problems of limited application, low product selectivity, environmental impact, etc., and achieve the effect of overcoming long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

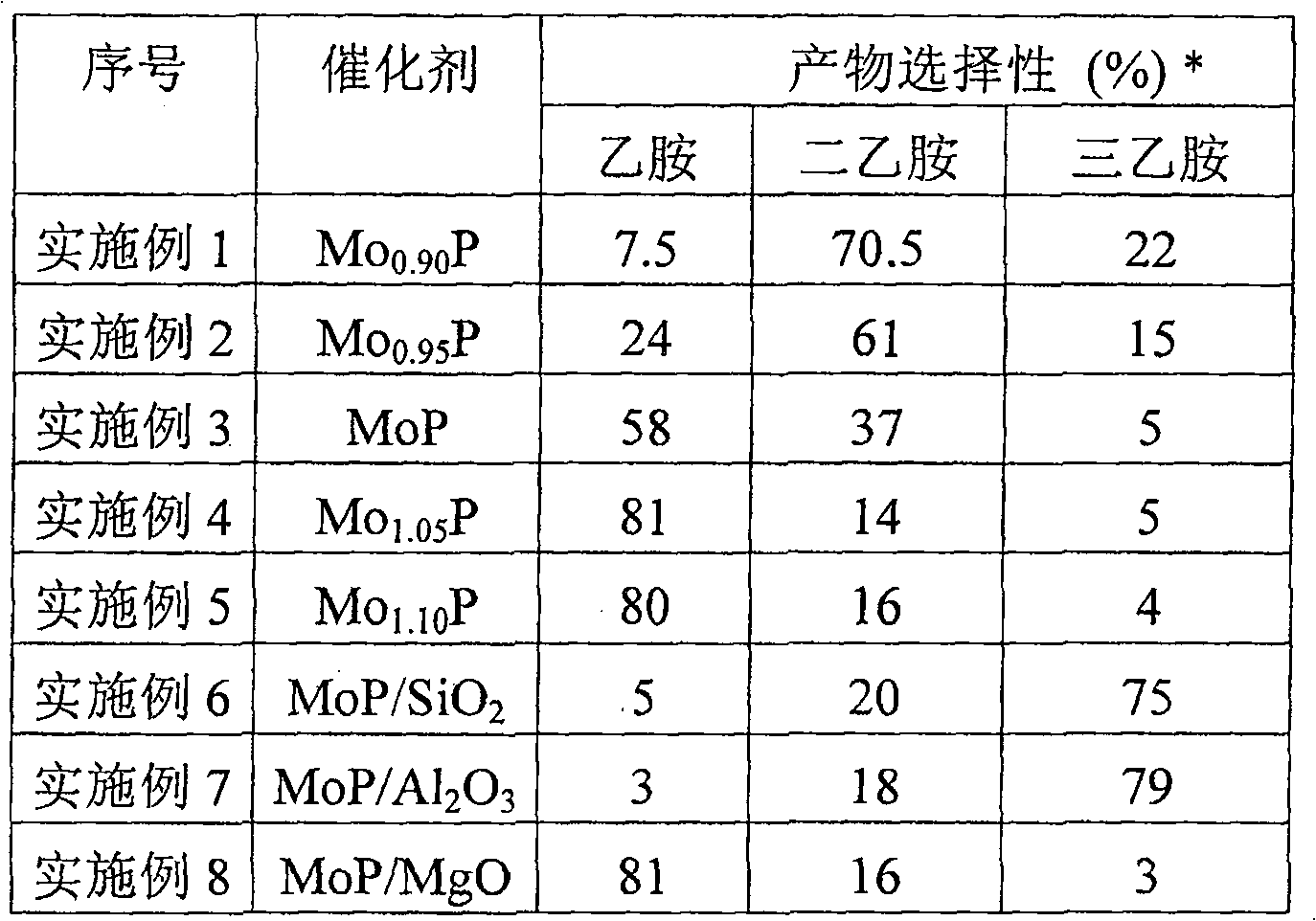

[0027] The pure-phase molybdenum phosphide prepared with a molybdenum-phosphorus ratio of 0.9 was used as a catalyst, and the hydrogenation reaction of acetonitrile was carried out in a miniature fixed-bed reactor. The reaction conditions are: 0.25 g catalyst, temperature 200°C, normal pressure, hydrogen flow rate 20ml / min, temperature of the saturator containing acetonitrile kept at 10°C. The product was analyzed by gas chromatography and hydrogen flame detector.

Embodiment 2-5

[0029] With embodiment 1, just change the feeding ratio of molybdenum phosphorus, reaction result is listed in table 1.

Embodiment 6

[0031] Same as Example 1, except that molybdenum and phosphorus compounds containing molybdenum and phosphorus with a molybdenum-phosphorus ratio of 1 are dissolved and impregnated in a certain quality of SiO 2 On the basis of Mo mass, MoP / SiO with a loading of 30% was prepared 2 . The reaction results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com