Flat plate type heat conduction heat flux sensor based on direct temperature measurement

A technology of heat flow sensor and temperature sensor, which is applied in calorimeters, heat measurement, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve problems such as low precision, high cost, and complicated manufacturing process, and achieve high The effect of high-precision temperature measurement, easy manufacturing process, and small heat flow measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

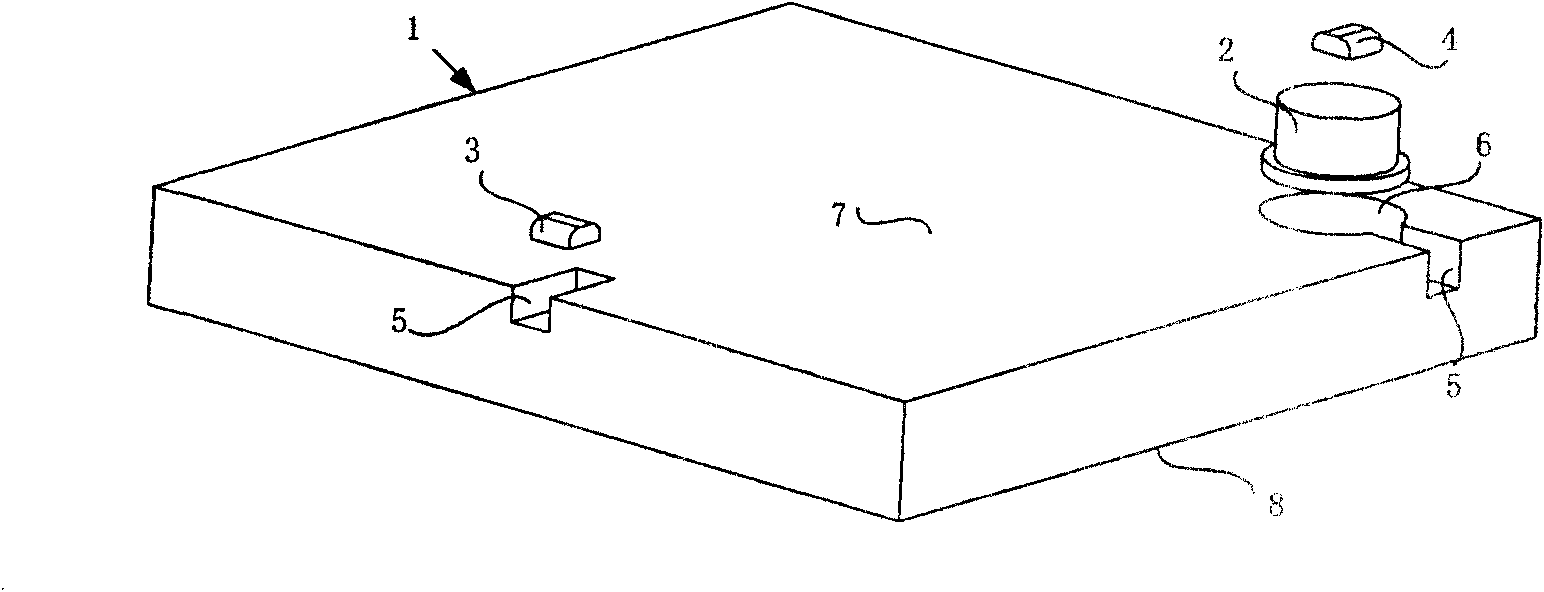

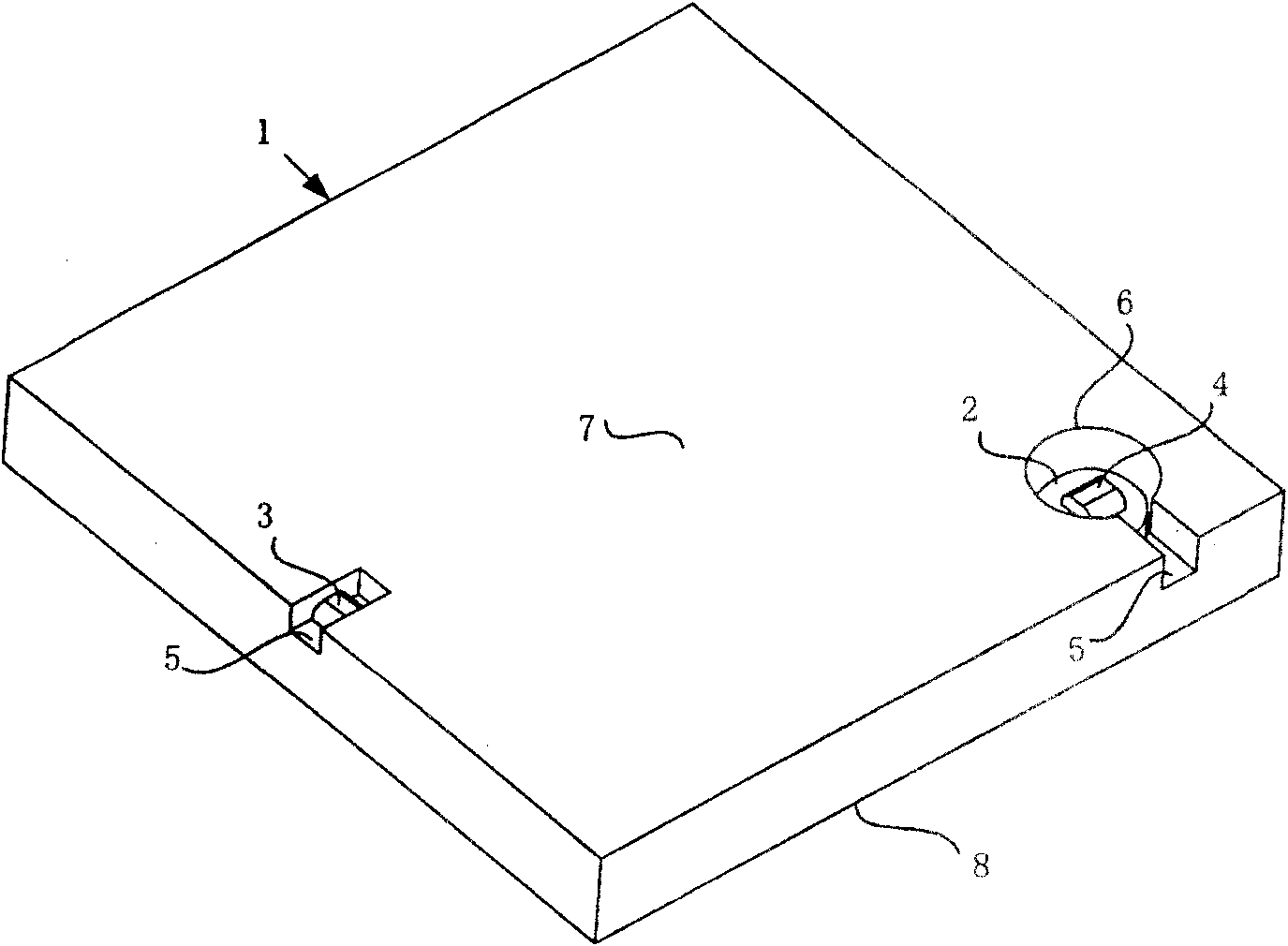

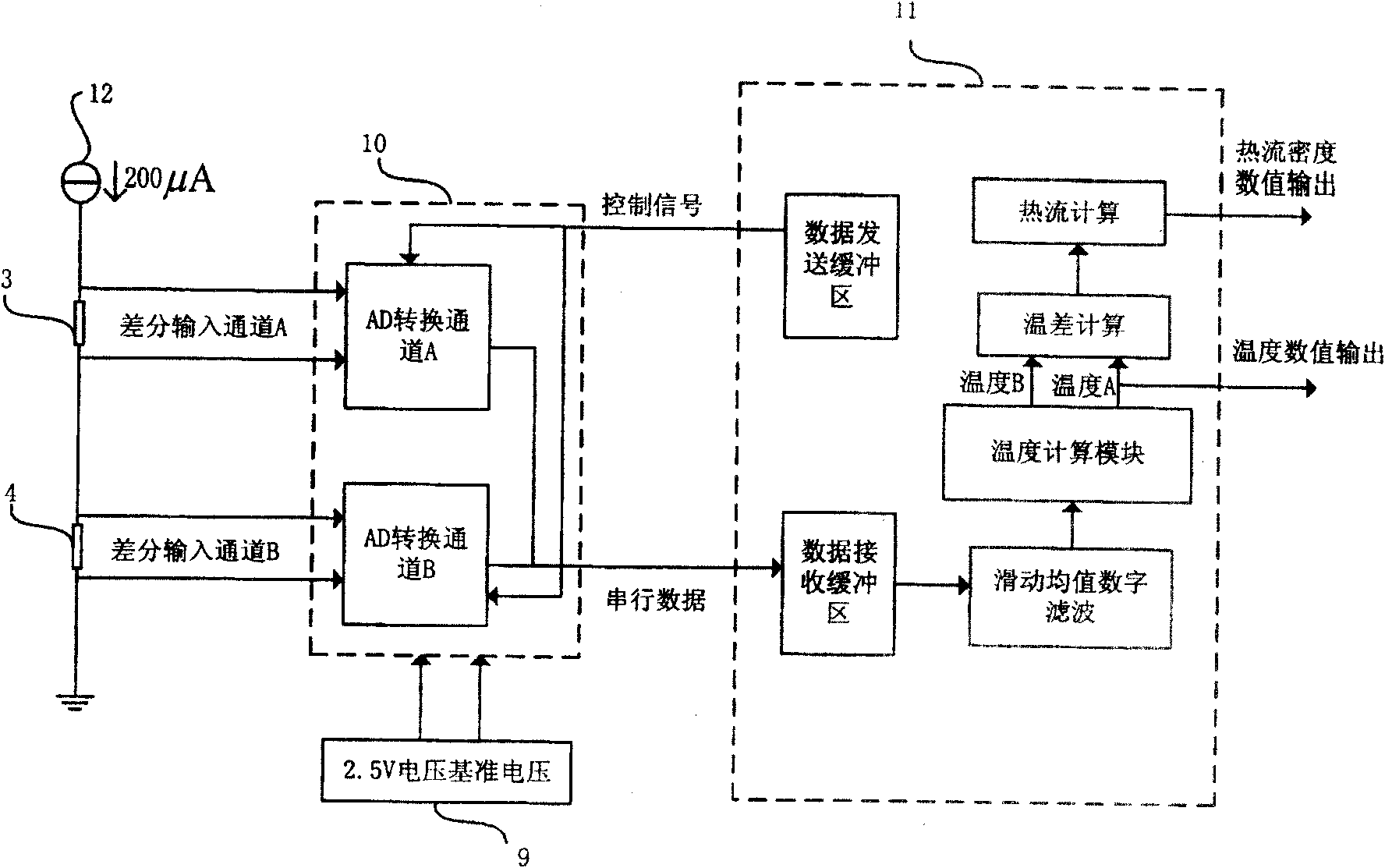

[0026] The present invention is a flat plate heat conduction heat flow sensor based on direct temperature measurement, such as figure 1 , figure 2 , image 3 As shown, it includes a temperature measurement unit and a measurement circuit. The temperature measurement unit includes: a flat plate 1, an embedded boss 2, two identical temperature sensors A3 and a temperature sensor B4. The upper surface 7 of the flat plate 1 is provided with two grooves 5, the grooves 5 are respectively located on two different sides of the upper surface 7, the depth of the grooves 5 is less than the thickness of the flat plate 1, and one of the grooves 5 is connected with a through hole 6 . The embedding boss 2 is tightly embedded in the through hole 6 after being coated with heat-conducting silicone grease, and the bottom of the embedding boss 2 is in the same plane as the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com